Floating bed bioreactor for deep nitrogen removal

A bioreactor and reactor technology, applied in special treatment targets, anaerobic digestion treatment, biological treatment devices, etc., can solve the problems to be improved, and achieve the effects of reasonable structure, high denitrification rate and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

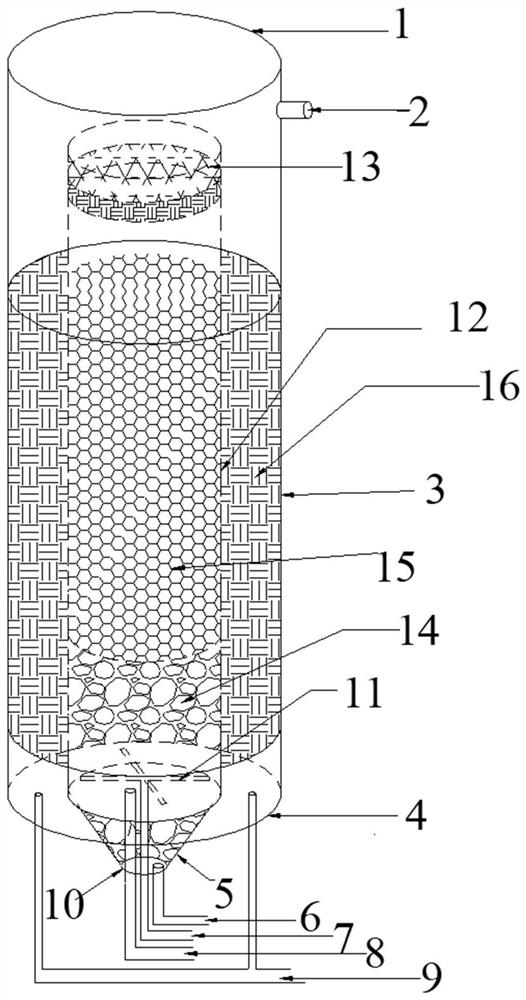

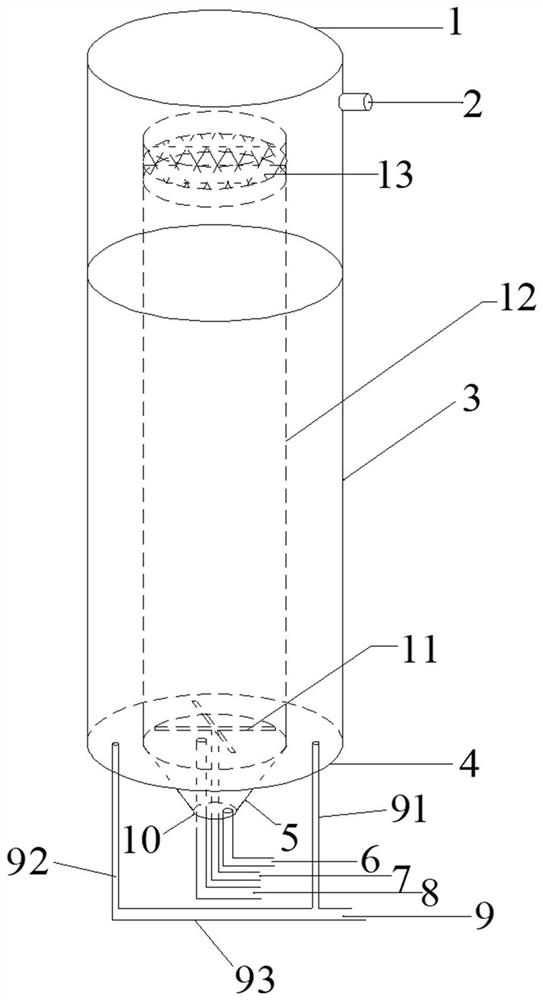

[0051] The preparation process of the floating bed bioreactor for treating low-concentration nitrate nitrogen regeneration water is as follows:

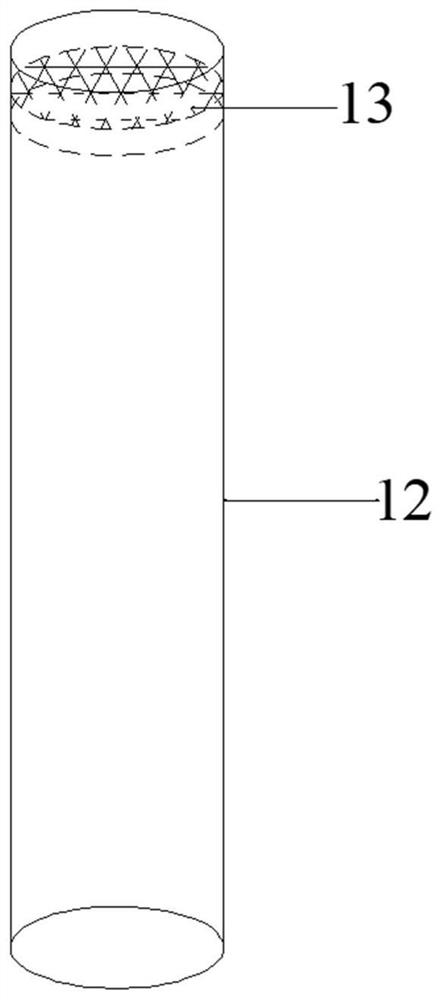

[0052] The floating bed bioreactor is made of plexiglass plate, the inner diameter of the reactor body is 60cm, the outer diameter is 61cm, and the height is 300cm. The movable cover plate has a diameter of 65cm and a thickness of 1cm, and is connected with the reactor body by a flange. The outer diameter of the circular base plate is 65cm, the inner diameter is 45cm, and the thickness is 1cm. The inner diameter of the inner cylinder of the reactor is 45 cm, the outer diameter is 46 cm, and the height is 275 cm. The height of the funnel pool is 30cm, the diameter of the upper part is 45cm, and the diameter of the bottom is 20cm. There is a water inlet pipe with an inner diameter of 32mm in the center of the movable floor at the bottom. Pipes, the diameters of which are 50mm and 55mm, respectively, and the symmetrical sides of the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com