A stacking device for semiconductor lead frames

A lead frame, semiconductor technology, applied in the direction of semiconductor/solid-state device manufacturing, transportation and packaging, electrical components, etc., can solve the problems of labor consumption and low production efficiency, and achieve the effect of saving labor, reducing production costs, and improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

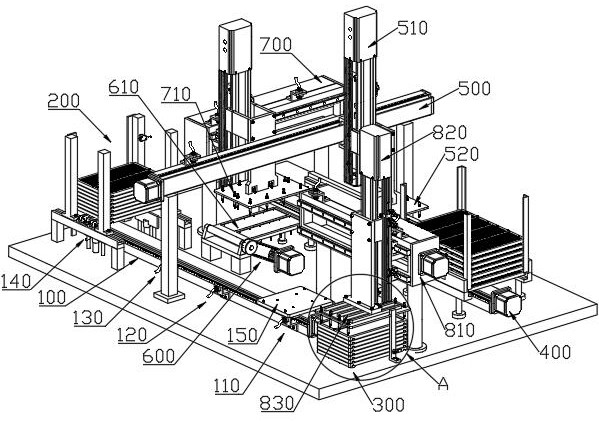

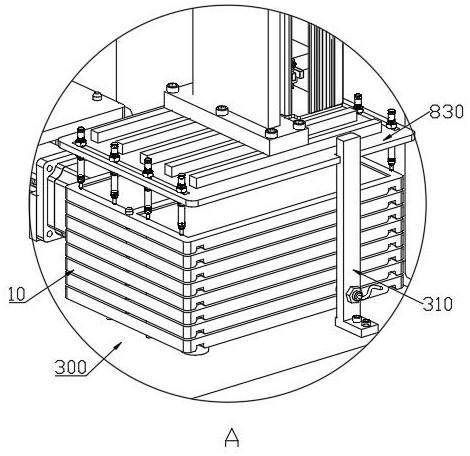

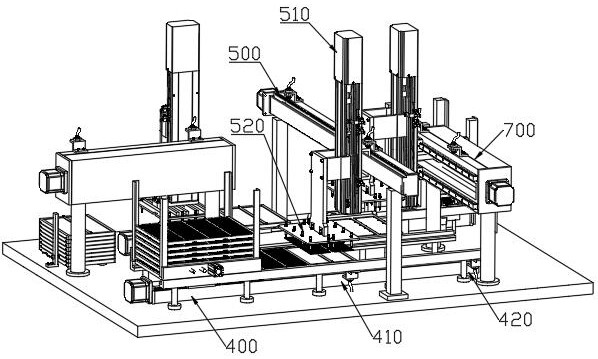

[0048] Such as Figure 1 to Figure 7 As shown, a semiconductor lead frame stacking device includes: a first linear mechanism 100, a stacking mechanism 200, a pad buffer mechanism 300, a second linear mechanism 400, a third linear mechanism 500, a rotating mechanism 600 and a first Four linear mechanism 700.

[0049] Specifically, the first linear mechanism 100 has a stacking mechanism 200 at one end and a pad buffer mechanism 300 at the other end for stacking empty pads. One end of the stacking mechanism 200 is sequentially provided with a pad mounting station 110, a first assembly station 120, a second assembly station 130, and a finished product stacking station 140, and the stacking mechanism 200 is arranged above the finished product stacking station 140. The linear mechanism 100 is slidably provided with a running plate 150. The running plate 150 is used to install and transfer the pad 10. The top surface of the pad 10 is used to carry the bottom lead frame, correspondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com