Air injection control system

A technology of air jet control and air jet tube, which is applied in the general control system, control/regulation system, program control, etc., can solve problems such as incompleteness, paper curling and uneven scanning, and uneven paper flatness, so as to improve stability and Accuracy, good prediction accuracy and adaptive ability, the effect of generalization ability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

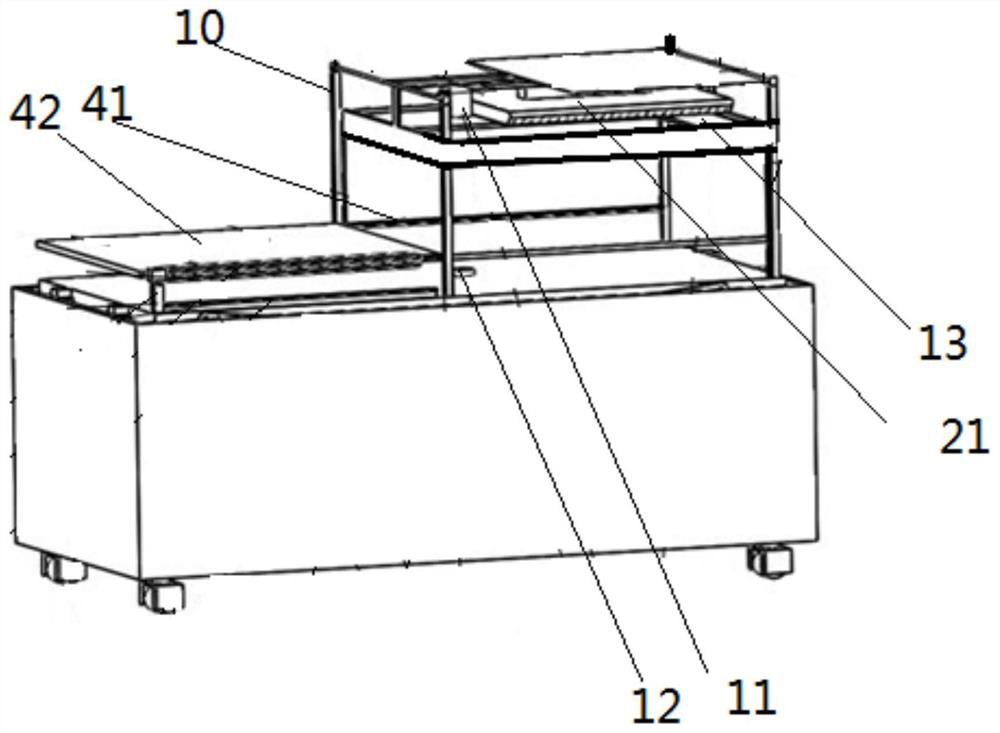

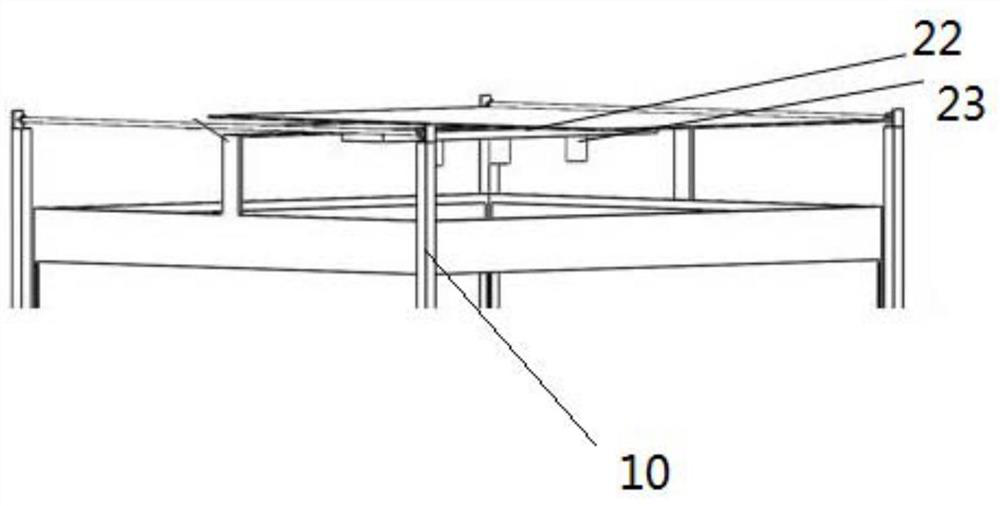

[0032] This embodiment provides an air injection control system, such as Figures 1 to 4 As shown, it is mainly composed of an object conveying device 4 , an air jet device 2 and a scanning device 1 . The object transfer device 4 is used to transfer the object to be scanned into the scanning area, the air jet device 2 is used to blow the object to be scanned flat, and the scanning device 1 is used to scan the object to be scanned.

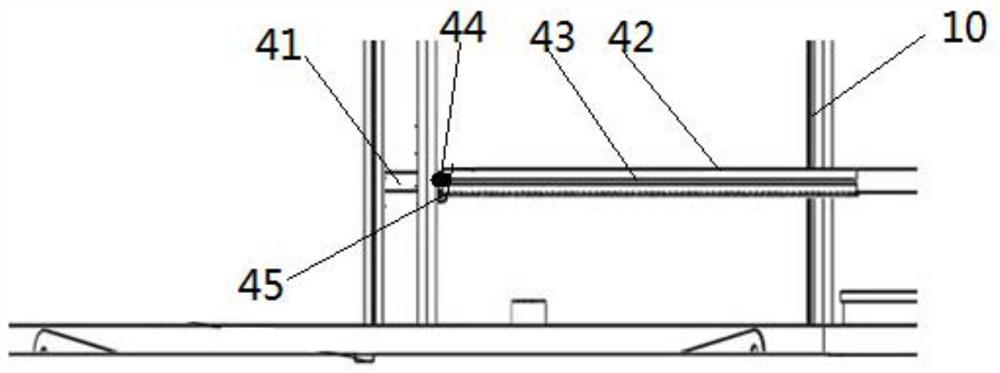

[0033] In the object conveying device 4, the conveying guide rail 41 is horizontally fixed on the frame 10, the transparent placing plate 42 is movably connected with the conveying guide rail 41, and the placing plate driving mechanism arranged on the frame 10 is used to drive the transparent placing plate 42 along the conveying guide rail. 41 moves horizontally into or out of the scanning area; in the placement plate drive mechanism, the first motor 45 is fixed on the frame 10, the rotating shaft of the gear 44 is fixed on the output shaft of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com