Temperature adjustment system for boiler of ultra-supercritical secondary reheating unit

A double reheating and ultra-supercritical technology, applied in superheating temperature control, steam superheating, lighting and heating equipment, etc., can solve the complex layout of the heating surface of the boiler, the complexity and difficulty of boiler steam temperature control, etc. problems, to achieve the effect of saving operation and maintenance costs, reducing initial investment, and avoiding wear and tear problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

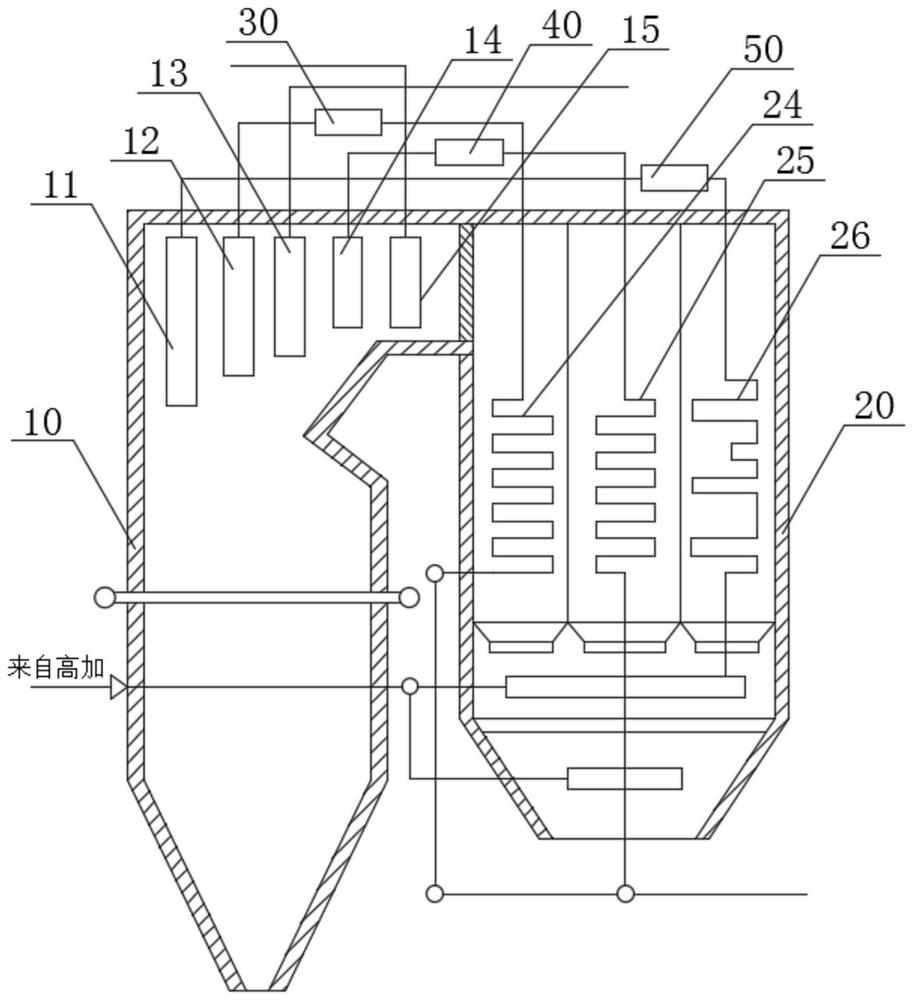

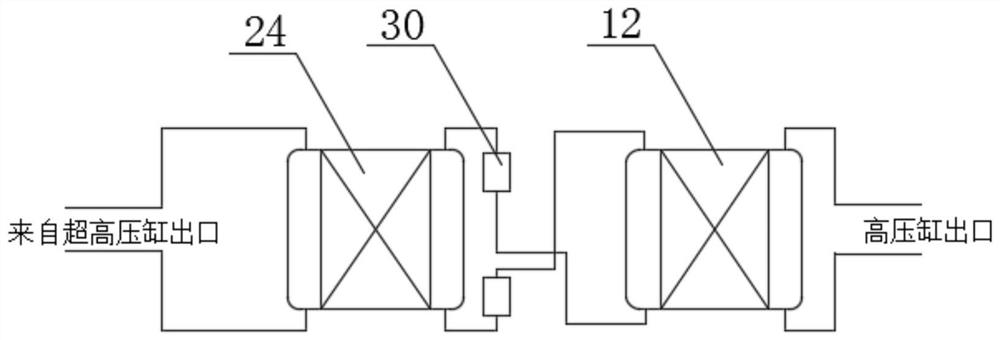

[0028] see Figure 1-4 , The present invention provides a technical solution: an ultra-supercritical double reheat unit boiler temperature adjustment system, comprising: a double reheat boiler 10 and a boiler tail 20 .

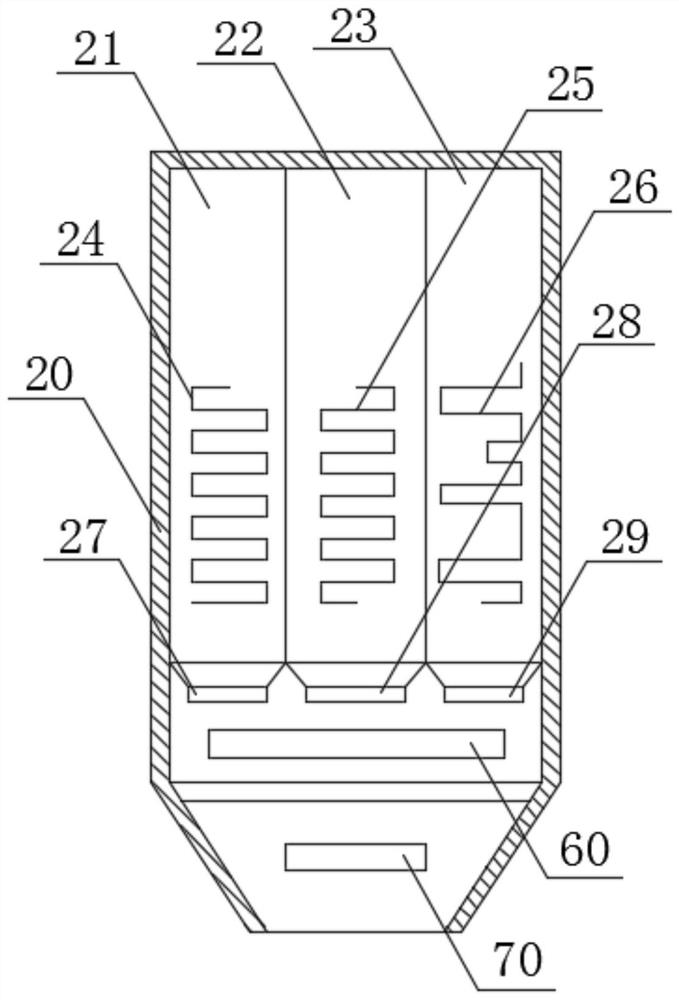

[0029] Wherein, the interior of the boiler tail 20 is divided into a front flue 21, a middle flue 22 and a rear flue 23 by a wall, and the middle flue 22 is arranged between the front flue 21 and the rear flue 23, the front flue A primary low-temperature reheater 24 is fixedly installed inside the flue 21 , a secondary low-temperature reheater 25 is fixedly installed inside the middle flue 22 , and a low-temperature superheater 26 is fixedly installed inside the rear flue 23 .

[0030] Wherein, the boiler tail 20 is fixedly installed at the tail of the double reheat boiler 10 .

[0031] Wherein, a first flue gas regulating baffle 27 is fixedly installed at the inner tail end of the front flue 21 , a second flue gas regulating baffle 28 is fixedly installed at...

Embodiment 2

[0042] see Figure 1-4 , The present invention provides a technical solution: an ultra-supercritical double reheat unit boiler temperature adjustment system, comprising: a double reheat boiler 10 and a boiler tail 20 .

[0043] Wherein, the interior of the boiler tail 20 is divided into a front flue 21, a middle flue 22 and a rear flue 23 by a wall, and the middle flue 22 is arranged between the front flue 21 and the rear flue 23, the front flue A primary low-temperature reheater 24 is fixedly installed inside the flue 21 , a secondary low-temperature reheater 25 is fixedly installed inside the middle flue 22 , and a low-temperature superheater 26 is fixedly installed inside the rear flue 23 .

[0044] Wherein, the boiler tail 20 is fixedly installed at the tail of the double reheat boiler 10 .

[0045] Wherein, a first flue gas regulating baffle 27 is fixedly installed at the inner tail end of the front flue 21 , a second flue gas regulating baffle 28 is fixedly installed at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com