Ball bearing with micro-texture on raceway surfaces of inner ring and outer ring and processing method thereof

A processing method and micro-texture technology, applied in the direction of machine tools, bearings, shafts and bearings with surface polishing, can solve the problems of small friction coefficient, inability to improve lubrication performance of ball bearings, difficult raceway lubrication, etc., to achieve improved lubrication effect, improving physical properties, increasing rigidity and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

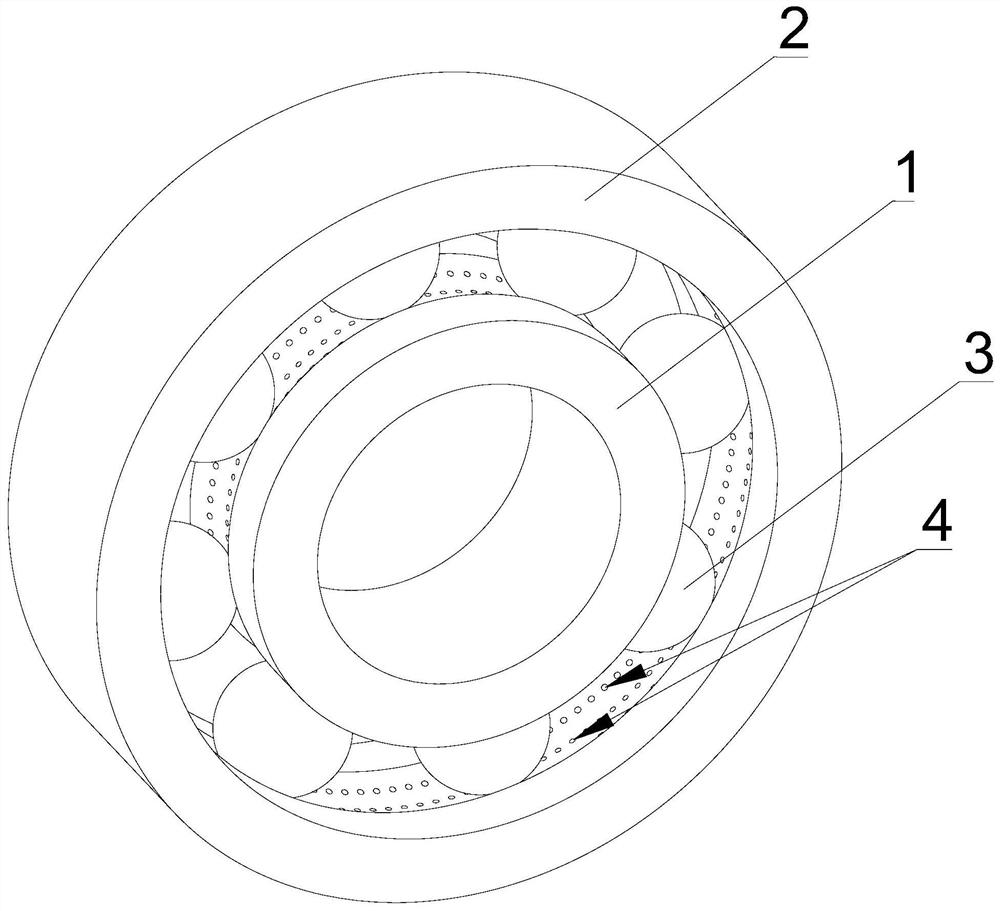

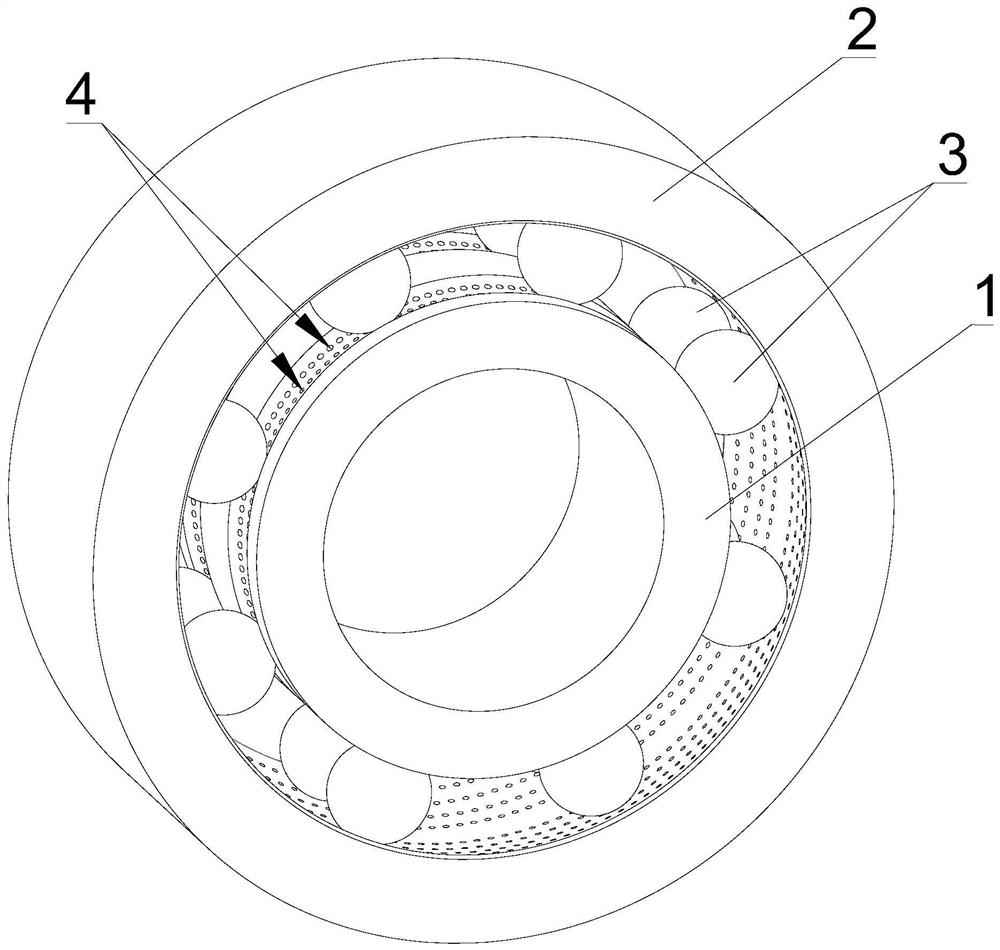

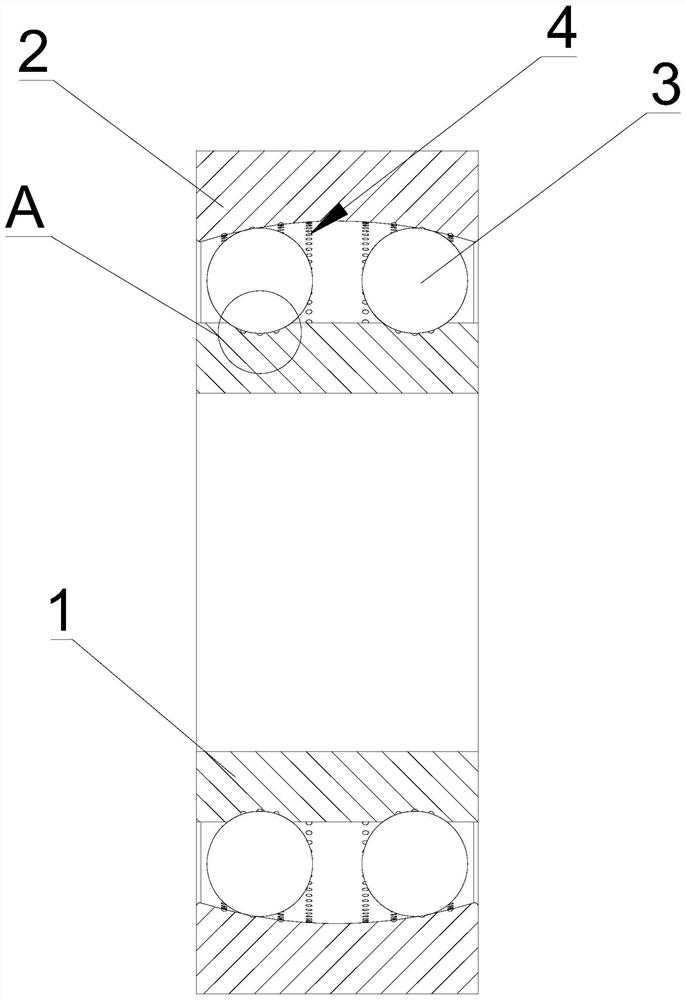

[0059] Among them, for the convenience of viewing, the reference signs are now uniformly explained: 1 is the inner ring of the bearing, 2 is the outer ring of the bearing, 3 is the rolling element, 4 is the pit, 5 is the laser, 6 is the laser beam, 7 is the convex lens, 8 is The raceway surface of the bearing inner ring, 9 is the workbench, 10 is the raceway surface of the bearing outer ring, 11 is the plane mirror, a is the surface micro-texture layer, b is the spray chemical physical film layer containing residual stress, c is the residual Stressed nitrogen-rich surface strengthening layer, d is the bearing matrix. Where h is the depth of the pit and d is the diameter of the pit. where L is the pit pitch.

[0060] In this embodiment, a ball bearing with a micro-texture on the raceway surface of the inner and outer rings, such as Figure 1-4 As shown, it includes the inner ring of the bearing, the outer ring of the bearing and the rolling elements arranged between the inner...

Embodiment 2

[0070] In this embodiment, a method for processing a ball bearing with a micro-texture on the raceway of the inner and outer rings, such as Figure 5-12 shown, including the following steps:

[0071] s1. Process the bearing inner ring and bearing outer ring according to the design size of the ball bearing;

[0072] s2. Carry out intensive grinding on the raceway surface of the bearing inner ring and the raceway surface of the bearing outer ring, and then clean the raceway surface of the bearing inner ring and the bearing outer ring;

[0073] s3. Use a multi-axis linkage laser processing system to perform rapid laser milling on the raceway surface of the bearing inner ring and the enhanced grinding layer of the raceway surface of the bearing outer ring, and prepare one or more groups of microstructures arranged along the axial direction of the bearing. Texture structure, each group of micro-texture structures includes a plurality of pits uniformly arranged along the circumfere...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com