Method for preparing clutch face sheet

A technology of clutch face and mixture, which is applied in the field of preparation of automobile clutch face, can solve the problems of large investment in rubber mixing equipment, harsh working environment, high labor intensity, etc., and achieve low cost, high labor intensity, and not easy to raise dust Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] This embodiment is used to illustrate the method for preparing a clutch face provided by the present invention.

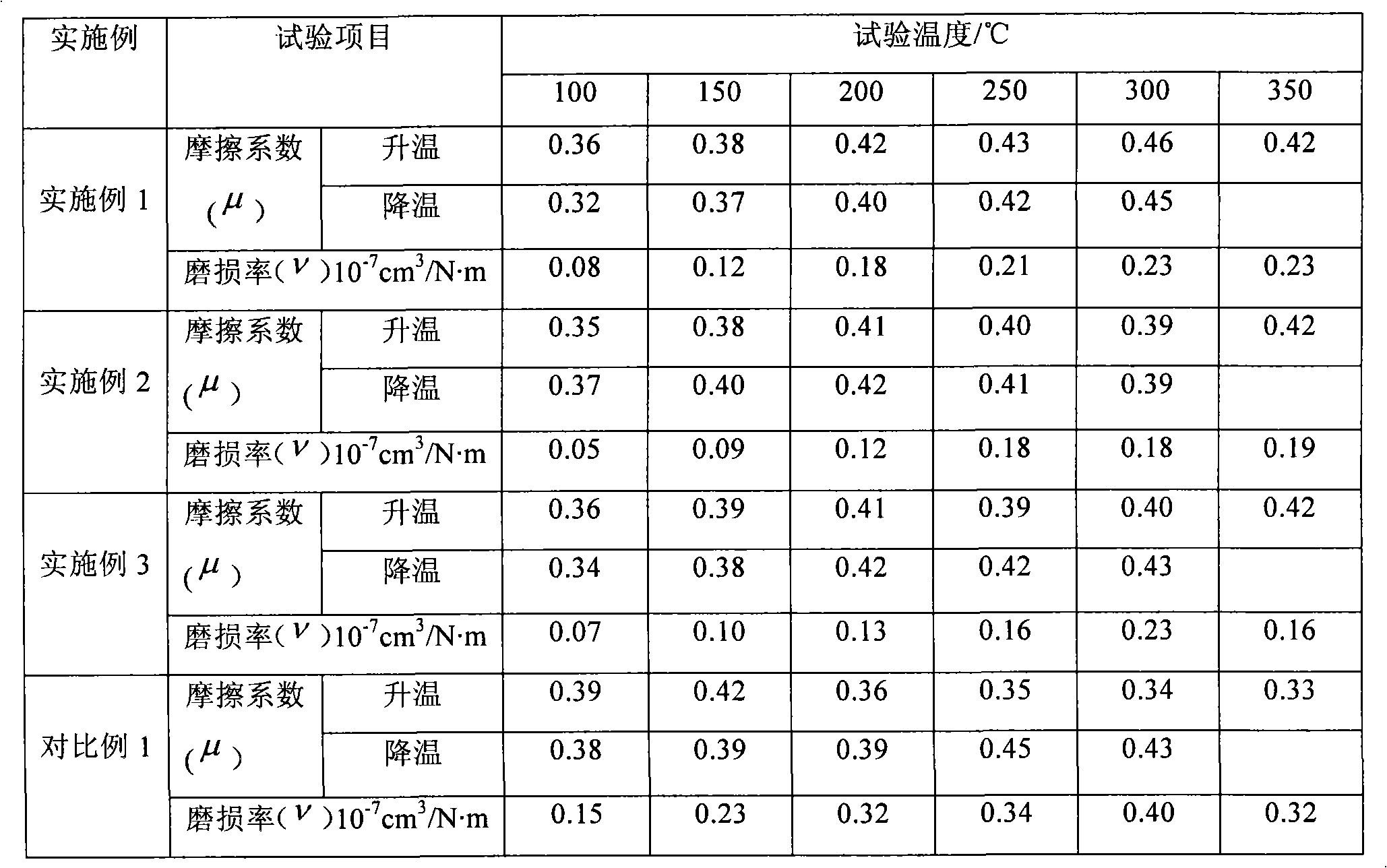

[0021] Crumble 20 kg of styrene-butadiene rubber into 20-30 mm particles in a crusher, pour the crushed particles into a stirring tank, add 10 kg of gasoline and stir for 15 minutes, then add 2 kg of sulfur, TMTD 0.5 kg, DOP 0.25 kg, feldspar 3 kg, fluorite 5 kg, zircon 7 kg, barium sulfate 14 kg, mica 10 kg, magnesium oxide 4 kg, carbon black 2 kg, natural graphite 10 kg, coke 10 kg , 3 kilograms of phenolic resins, pour in the stirring tank and stir for 80 minutes. The stirred glue and 35 kg of composite core-spun yarn are sizing-coated in the dipping machine, and the sizing-coated fibers are thermally dried for thermal drying, followed by winding, hot-press vulcanization, curing treatment, and subsequent machining Prepare the desired clutch product. The characterization parameters of the friction performance of the clutch face are shown in Table 1, and ...

Embodiment 2

[0023] This embodiment is used to illustrate the method for preparing a clutch face provided by the present invention.

[0024] 20 kg of styrene-butadiene rubber is crushed into 2-20mm particles in a crusher, the crushed particles are poured into a stirring tank, 4 kg of toluene is added and stirred for 15 minutes, and then 2 kg of sulfur and TMTD 0.5 kg, DOP 0.25 kg, feldspar 3 kg, fluorite 5 kg, zircon 7 kg, barium sulfate 14 kg, mica 10 kg, magnesium oxide 4 kg, carbon black 2 kg, natural graphite 10 kg, coke 10 kg, 3 kilograms of phenolic resins were poured into a stirring tank and stirred for 80 minutes. The stirred glue and 35 kg of composite core-spun yarn are sizing-coated in the dipping machine, and the sizing-coated fibers are thermally dried, and then wound, hot-pressed vulcanized, solidified, and subsequently machined to prepare the required Clutch products. The characterization parameters of the friction performance of the clutch face are shown in Table 1, and t...

Embodiment 3

[0026] This embodiment is used to illustrate the method for preparing a clutch face provided by the present invention.

[0027] 20 kg of styrene-butadiene rubber is crushed into 30-40mm particles in a crusher, the crushed particles are poured into a stirring tank, 8 kg of cyclohexane is added and stirred for 15 minutes, and then 2 kg of weighed sulfur, TMTD 0.5 kg, DOP 0.25 kg, feldspar 3 kg, fluorite 5 kg, zircon 7 kg, barium sulfate 14 kg, mica 10 kg, magnesium oxide 4 kg, carbon black 2 kg, natural graphite 10 kg, coke 10 kg 1 kg, 4 kg of phenolic resin, poured into the stirring tank and stirred for 80 minutes. The stirred glue and 35 kg of composite core-spun yarn are sizing-coated in the dipping machine, and the sizing-coated fibers are thermally dried, and then wound, hot-pressed vulcanized, solidified, and subsequently machined to prepare the required Clutch products. The characterization parameters of the friction performance of the clutch face are shown in Table 1, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com