Thermal expansion turbine steam turbine

A steam turbine and thermal expansion technology, applied in gas turbine devices, mechanical equipment, engine components, etc., can solve the problems of low compression ratio, complex process, low thermal efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

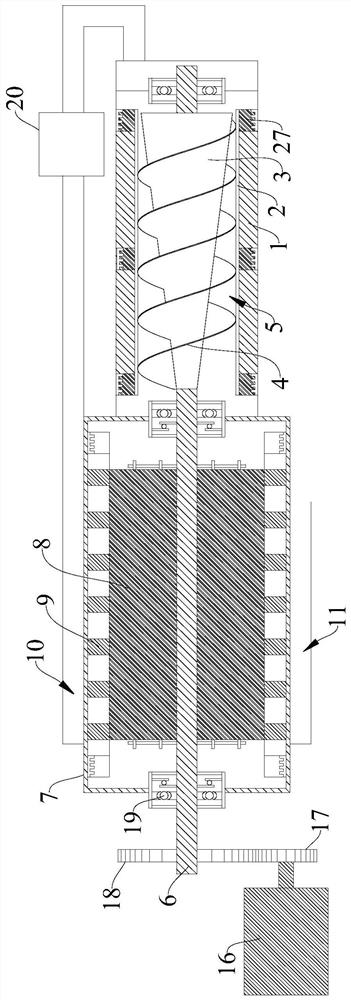

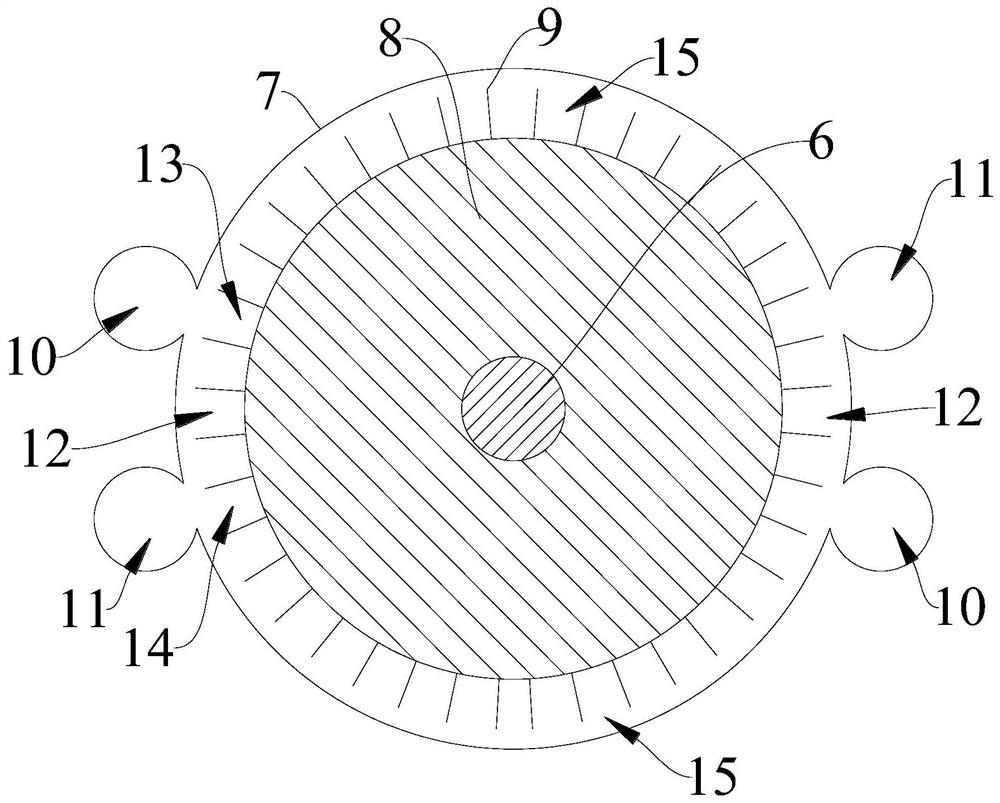

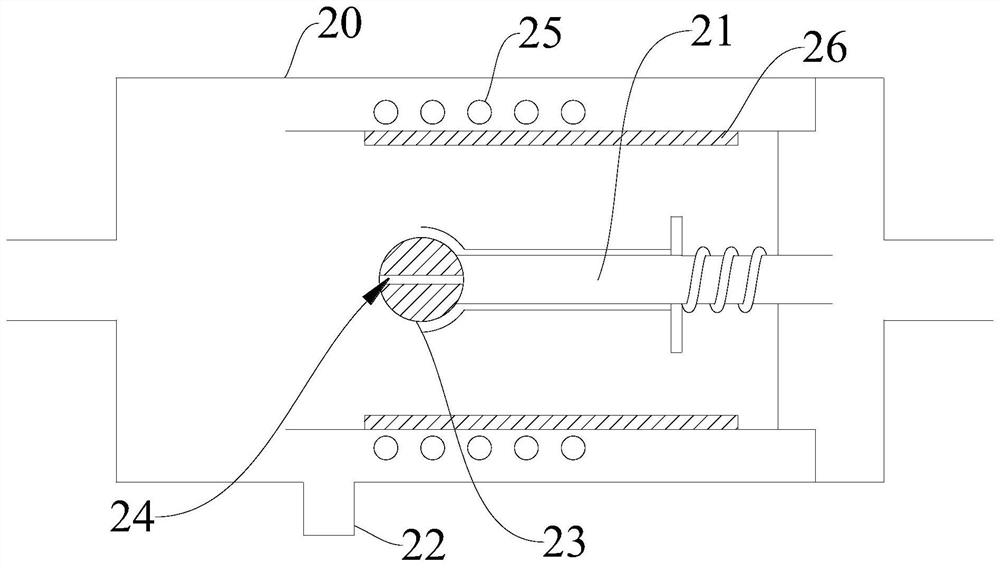

[0045] Please refer to Figure 1-Figure 3 , the present embodiment provides a thermal expansion turbine, including a screw compressor, a turbine, a starting assembly, and a thermal expansion device. A conical wheel 3 is provided, and the outer wall of the conical wheel 3 is provided with a plurality of screw fans 4 along its axial direction; an air chamber is formed between every two adjacent screw fans 4, the outer wall of the conical wheel 3 and the inner wall of the gas collector 2 Spiral 5, the cross-sectional area of the air chamber spiral 5 gradually decreases from the tip of the conical wheel 3 to the other end; the larger end of the air chamber spiral 5 is provided with an air inlet, and the air chamber spiral One end of the smaller cross-sectional area of 5 is provided with an exhaust port; the thermal expansion device communicates with the exhaust port and the turbine steam turbine respectively;

[0046] When working, the start-up component is first assisted to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com