Air foam flooding method for reducing gas channeling for underground thickened oil exploitation and air foaming agent of foam flooding for reducing gas channeling for underground thickened oil exploitation

A technology for air foam flooding and downhole heavy oil, which is applied in the fields of production of fluids, chemical instruments and methods, and earth-moving drilling, etc., can solve problems such as poor oil washing ability, reduce the occurrence of gas channeling, and improve the efficiency of control and flooding and oil washing. , the effect of good foam quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The downhole heavy oil development adopts the air foam flooding method to reduce gas channeling, including the following steps:

[0031] S1 preparation work: collect dynamic production data in the work area, prepare sufficient water, ensure sufficient gas source, prepare sufficient foaming agent, and install gas pressure sensor and nitrogen detector into the casing of the production well;

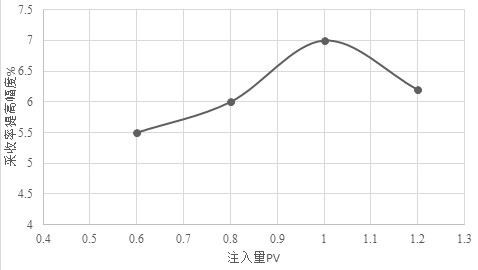

[0032]S2 Pre-injection: Advance water injection at one end of the water injection well. When the water content near the production well reaches 70%, the pre-air foam is injected. The foaming method of the pre-air foam is ground foaming. The ground mixing time is 18 minutes, the injection method is gas-liquid simultaneous injection, the gas-liquid volume ratio is 1.25:1, the injection rate is 7.5L / min, and the injection volume is 0.6PV. The nitrogen content of the production well is monitored in real time. When the mass content is 15-30%, reduce the injection rate to the minimum value...

Embodiment 2

[0038] This embodiment is basically the same as Embodiment 1, except that the water cut near the production well is different when the injection starts, so the gas-liquid volume ratio, injection rate and injection volume need to be adjusted according to the water cut.

[0039] S2 Pre-injection: Advance water injection at one end of the water injection well. When the water content near the production well reaches 75%, the pre-air foam is injected. The foaming method of the pre-air foam is ground foaming. The ground mixing time is 15 minutes, the injection method is gas-liquid simultaneous injection, the gas-liquid volume ratio is 1.35:1, the injection rate is 8L / min, and the injection volume is 1PV. The nitrogen content of the production well is monitored in real time. When the mass content of nitrogen When it is 15-30%, reduce the injection rate to the minimum value of the preset value. When the mass content of nitrogen is 30-50%, reduce the injection rate to 3.5L / min. When the...

Embodiment 3

[0044] This embodiment is basically the same as Embodiment 1, except that the water cut near the production well is different when the injection starts, so the gas-liquid volume ratio, injection rate and injection volume need to be adjusted according to the water cut.

[0045] S2 Pre-injection: Advance water injection at one end of the water injection well. When the water content near the production well reaches 80%, the pre-air foam is injected. The foaming method of the pre-air foam is ground foaming. The ground mixing time is 20 minutes, the injection method is gas-liquid simultaneous injection, the gas-liquid volume ratio is 1.45:1, the injection rate is 9L / min, and the injection volume is 1.2PV. The nitrogen content of the production well is monitored in real time. When the quality of nitrogen When the content is 15-30%, reduce the injection speed to the minimum value of the preset value. When the mass content of nitrogen is 30-50%, reduce the injection speed to 4L / min. Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com