Mechanical multi-group rear cantilever transverse moving type parking device

A technology of parking equipment and rear cantilever, which is applied in the field of mechanical multi-group rear cantilever lateral movement parking equipment, and can solve the problem of few parking spaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

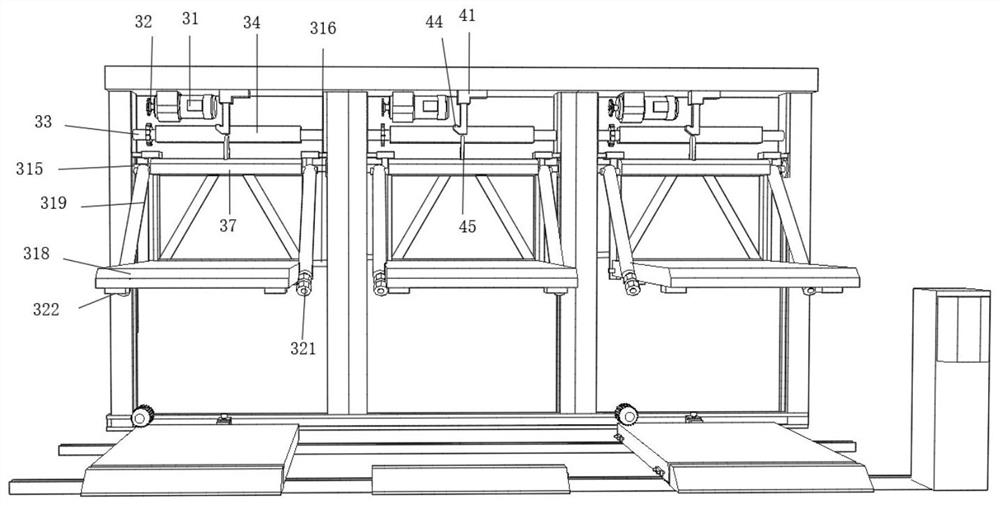

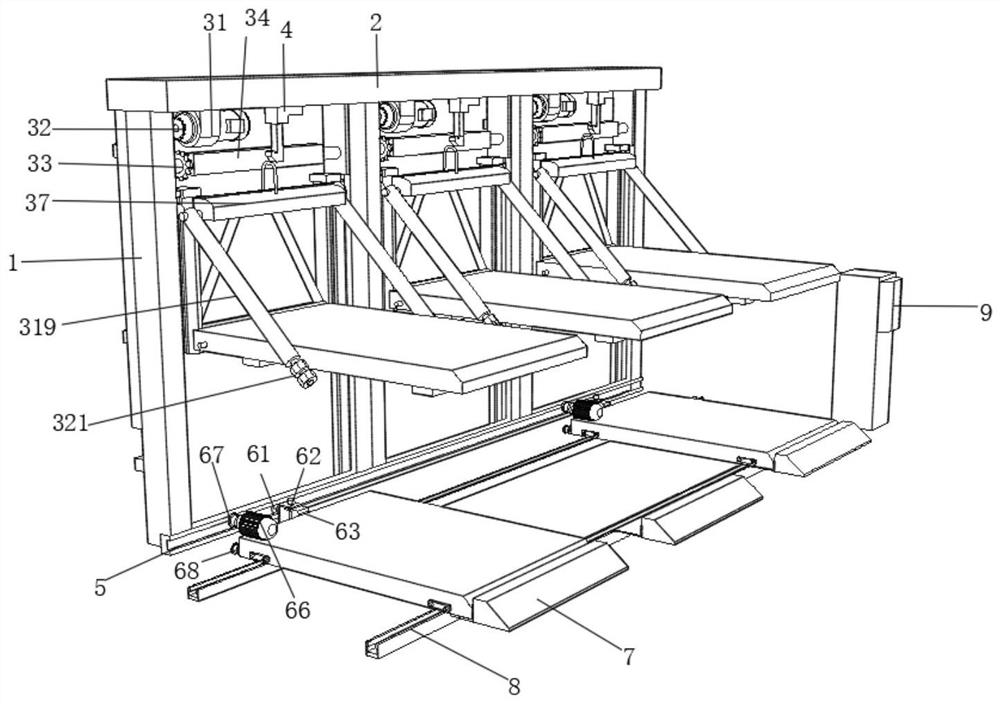

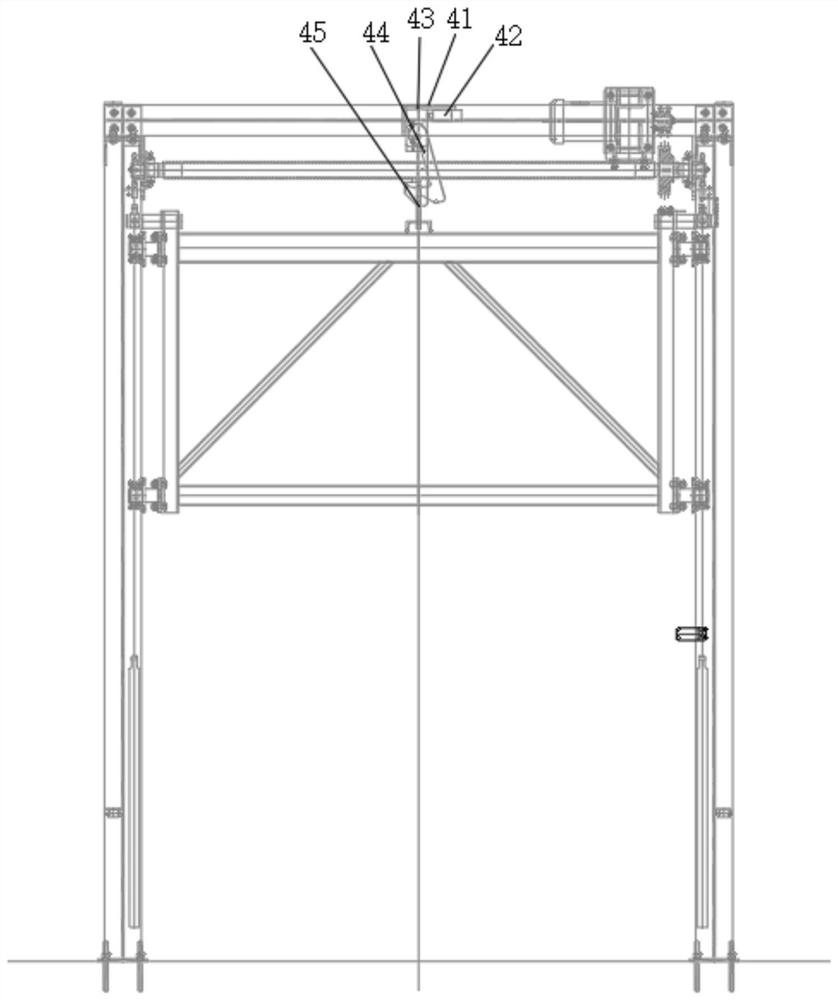

[0023] see Figure 1-6 , the present invention provides the following technical solutions: a mechanical multi-group rear cantilever traverse type parking equipment, including a support frame 1, a chute is provided on one side of the support frame 1, and an upper beam 2 is fixedly connected to the top of the support frame 1, and the upper beam 2 A lifting mechanism 3 is fixedly installed on one side of the bottom, an anti-falling device 4 is fixedly installed in the middle of the bottom end of the upper beam 2, and a guide rail 5 is fixedly connected to the bottom end of the support frame 1, and the guide rail 5 is slidingly connected to a translation device 6, and the translation device 6 One end is provided with a buffer seat 7, and the bottom end of the translation device 6 is provided with a slide rail 8, and one end of the slide rail 8 is fixedly connected with a switch panel 9.

[0024] Preferably, the lifting mechanism 3 includes a stepping motor 31 fixedly connected to ...

Embodiment 2

[0033] The difference from Embodiment 1 is that this embodiment includes a manufacturing method of the support pad:

[0034] 1) Mix 1-2 parts of carbon black, 1-3 parts of barium oxide, 5-7 parts of niobium pentoxide, 8-12 parts of erbium oxide, 5-7 parts of neodymium oxide, and 8-12 parts of hexamethyldisilazane 28-30 parts of reinforcing agent, 28-30 parts of accelerator and 28-30 parts of vulcanizing agent, 28-30 parts of ferric oxide, 28-30 parts of structural control agent, 28-30 parts of graphite powder into powder, and after sieving, pour it into a three-dimensional mixer for mixing treatment to obtain a mixed powder for subsequent use;

[0035] 2) Combine 22-26 parts of styrene-butadiene rubber, 7-11 parts of dammar resin, 11-19 parts of terpene resin, 12-22 parts of polyester resin, 28-30 parts of active agent, and 28-30 parts of tackifying resin Pour it into a container, then heat it to 150°C until the solid material is completely melted, stir well, and make a mixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com