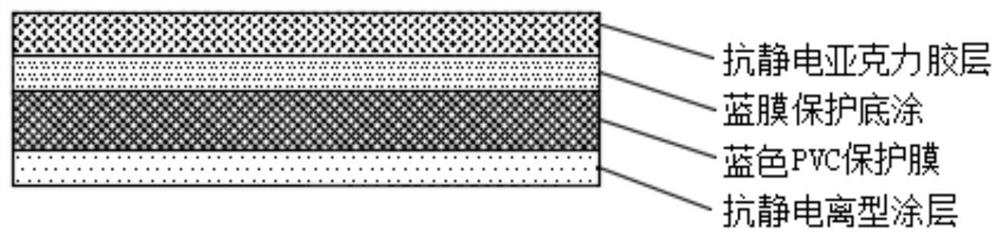

Antistatic semiconductor chip cutting protective film

An antistatic, semiconductor technology, applied in film/sheet release coatings, conductive coatings, conductive adhesives, etc., can solve the problems of slow release of plasticizers, unfavorable coating leveling, shrinkage and other problems, Achieve the effect of improving high temperature resistance and solvent resistance, stable peel strength, and not easy to shrink

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) Preparation of antistatic release agent:

[0019] Weigh 10 parts of the main agent methyl silicone oil, 0.02 parts of the platinum catalyst, 0.4 parts of the antistatic agent, and 100 parts of the diluent; put the platinum catalyst into the main agent methyl silicone oil, add an appropriate amount of diluent and stir evenly; add the antistatic agent Stir well with the remaining diluent; after the antistatic release agent is prepared, it is ready to be coated on the bright surface of the PVC blue film.

[0020] (2) Preparation of blue film protective primer:

[0021] Step 1: Weigh 30 parts of water-based polyurethane resin, 4 parts of co-solvent, and 10 parts of solvent;

[0022] Step: 2: mix the polyurethane resin and the co-solvent together, add an appropriate amount of solvent, and stir evenly;

[0023] Step 3: Weigh 1 part of curing agent, add an appropriate amount of solvent, mix and stir evenly;

[0024] Step 4: Add the solution in step 3 to the turbid solut...

Embodiment 2

[0051] (1) Preparation of antistatic release agent:

[0052] Weigh 40 parts of the main agent methyl silicone oil, 1 part of the platinum catalyst, 1 part of the antistatic agent, and 150 parts of the diluent; put the platinum catalyst into the main agent methyl silicone oil, add an appropriate amount of diluent and stir evenly; add the antistatic agent Stir well with the remaining diluent; after the antistatic release agent is prepared, it is ready to be coated on the bright surface of the PVC blue film.

[0053] (2) Preparation of blue film protective primer:

[0054] Step 1: Weigh 40 parts of water-based polyurethane resin, 7 parts of cosolvent, and 20 parts of solvent;

[0055] Step: 2: mix the polyurethane resin and the co-solvent together, add an appropriate amount of solvent, and stir evenly;

[0056] Step 3: Weigh 2 parts of curing agent, add an appropriate amount of solvent, mix and stir evenly;

[0057] Step 4: Add the solution in step 3 to the turbid solution in ...

Embodiment 3

[0084] (1) Preparation of antistatic release agent:

[0085] Weigh 60 parts of main agent methyl silicone oil, 2 parts of platinum catalyst, 2 parts of antistatic agent, and 200 parts of diluent; put the platinum catalyst into the main agent methyl silicone oil, add an appropriate amount of diluent and stir evenly; add antistatic agent Stir well with the remaining diluent; after the antistatic release agent is prepared, it is ready to be coated on the bright surface of the PVC blue film.

[0086] (2) Preparation of blue film protective primer:

[0087] Step 1: Weigh 50 parts of water-based polyurethane resin, 10 parts of co-solvent, and 30 parts of solvent;

[0088] Step: 2: mix the polyurethane resin and the co-solvent together, add an appropriate amount of solvent, and stir evenly;

[0089] Step 3: Weigh 3 parts of curing agent, add an appropriate amount of solvent, mix and stir evenly;

[0090] Step 4: Add the solution in step 3 to the turbid solution in step 2, mix and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com