Long-acting high-voltage direct-current breakdown resistant polyethylene resin as well as preparation method and application thereof

A polyethylene resin, DC breakdown technology, applied in the field of polyethylene resin, can solve the problems of easy migration and precipitation of voltage-resistant monomers, low breakdown field strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

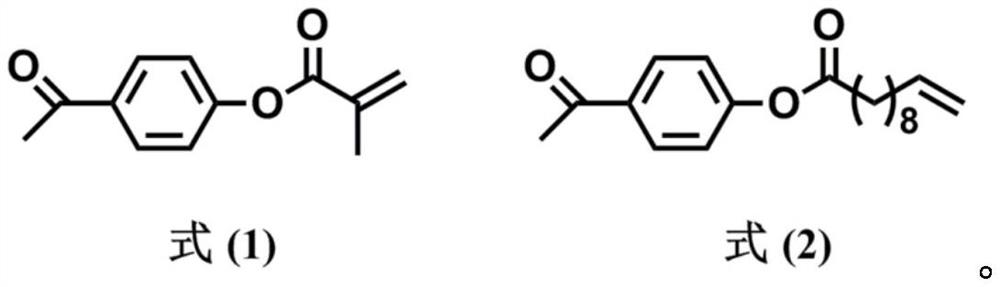

[0035] The present invention provides a preparation method of a voltage-resistant monomer with a structure of formula (1), but is not limited thereto: dissolving p-hydroxyacetophenone in 2-butanone, then adding triethylamine, under the protection of an inert atmosphere (preferably Nitrogen), stirring at 0-4°C (stirring speed is not particularly limited, usually 115r / min) while adding the ether solution of methacryloyl chloride dropwise, the drop rate is preferably 5-7ml / min, after the dropwise addition is completed, the reaction 3 -4h, the obtained reaction solution was first washed with ether, then the filtrate was washed successively with 5wt% sodium hydroxide solution and deionized water, and finally the upper layer filtrate was separated, and the solvent was evaporated with a rotary vacuum evaporator, and the product obtained was heated at 60° C. Dry in a vacuum drying oven until constant weight to obtain a voltage-resistant monomer of formula (1) structure;

[0036] Where...

Embodiment 1

[0047] At normal temperature, normal pressure, under air atmosphere, the ethylene-1-butene copolymer resin (weight-average molecular weight 108000) that butene mass percent content is 6.7% carries out pre-irradiation with the beta ray of electron accelerator, pre-irradiation The dose is 20kGy.

[0048] Dissolve 0.2 mol of p-hydroxyacetophenone in 349 mL of 2-butanone, then add 0.2 mol of triethylamine, blow in nitrogen, keep stirring, and keep the reaction temperature at 0°C. Subsequently, 0.2 mol of methacryloyl chloride was dissolved in 149.5 mL of ether, and was added dropwise to the above mixed solution with a dropping funnel for 30 minutes. After the dropwise addition was completed, the reaction was continued for 3 hours. The reaction solution is filtered, washed with ether first, the filtrate is collected, then the filtrate containing the product is washed with 5wt% sodium hydroxide solution, and the filtrate containing the product is washed with deionized water, and fin...

Embodiment 2

[0058] At normal temperature, under normal pressure, under air atmosphere, the ethylene-1-octene copolymer resin (weight average molecular weight 136000) that octene mass percent content is 8.7% carries out pre-irradiation with the beta ray of electron accelerator, pre-irradiation The dose is 30kGy.

[0059] Dissolve 0.3 mol of p-hydroxyacetophenone in 340 mL of 2-butanone, then add 0.36 mol of triethylamine, blow in nitrogen, keep stirring, and keep the reaction temperature at 4°C. Subsequently, 0.44 mol of methacryloyl chloride was dissolved in 174.5 mL of ether, and was added dropwise to the above mixed solution with a dropping funnel for 25 minutes. After the dropwise addition was completed, the reaction was carried out for 4 hours. The reaction solution was filtered, first washed with ether, the filtrate was collected, then the filtrate containing the product was washed with 5wt% sodium hydroxide solution, and the filtrate containing the product was washed with deionized ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com