Coagulation process treatment method for machine-made sand cleaning water

A treatment method and machine-made sand technology, applied in water/sewage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve problems such as incomplete treatment of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

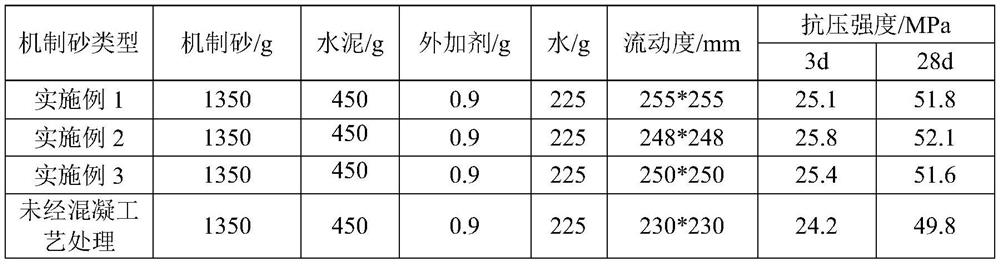

Examples

Embodiment 1

[0021] 1. Dilute water glass to a concentration of 8%, then slowly add to dilute H under high-speed stirring 2 SO 4 In the solution, the pH is controlled at about 3, and polymerized at 50° C. for a period of time to obtain a polysilicic acid solution. FeSO was then distilled with distilled water 4 . 7H 2 O is configured into a solution with a certain concentration, and according to the molar ratio of Si / Fe=1 / 1, the ferrous salt is added to the prepared polysilicate solution, fully stirred for 60 minutes, and aged to obtain polysilicate ferric salt;

[0022] 2. The cleaning liquid includes organic coagulant dimethyl diallyl ammonium sulfate solution and inorganic coagulant polysilicate iron salt solution, wherein the concentration of dimethyl diallyl ammonium sulfate solution is 0.4 (wt)% , polysilicate iron salt solution is 0.2 (wt)%;

[0023] 3. Collect the turbid waste water formed by cleaning the machine-made sand, add the cleaning solution evenly into the turbid water...

Embodiment 2

[0026] 1. Dilute water glass to a concentration of 5%, then slowly add to dilute H under high-speed stirring 2 SO 4 In the solution, the pH is controlled at about 3, and polymerized at 60° C. for a period of time to obtain a polysilicic acid solution. Then use distilled water to make industrial aluminum sulfate into a solution with a certain concentration. According to the molar ratio of Si / (Al)=1.5 / 1, add the aluminum salt into the prepared polysilicate solution, stir it thoroughly for 40 minutes, and then age it to obtain the polysilicate. Aluminum silicate;

[0027] 2. The cleaning solution includes organic coagulant dimethyl diallyl ammonium chloride solution and inorganic coagulant aid polysilicate aluminum salt solution, wherein the concentration of dimethyl diallyl ammonium chloride solution is 0.3 (wt )%, the polysilicate aluminum salt solution is 0.15 (wt)%;

[0028] 3. Separation of mud and water: collect the turbid waste water formed by cleaning the machine-made ...

Embodiment 3

[0031] 1. Dilute water glass to a concentration of 8%, then slowly add to dilute H under high-speed stirring 2 SO 4 In the solution, the pH is controlled at about 2, and polymerized at 60° C. for a period of time to obtain a polysilicic acid solution. FeSO was then distilled with distilled water 4 . 7H 2 O and industrial aluminum sulfate are configured into a solution of a certain concentration, wherein n(Fe):n(Al)=1:1, and the ferrous salt and aluminum salt are mixed according to the molar ratio of Si / (Fe+Al)=1 / 1 Add it into the prepared polysilicate solution, stir thoroughly for 30 minutes, and then age to obtain polyaluminum iron silicate;

[0032] 2. The cleaning solution includes organic coagulant dimethyl diallyl ammonium sulfate solution and inorganic coagulant polyaluminum iron silicate solution, wherein the concentration of dimethyl diallyl ammonium sulfate solution is 0.4 (wt)% , polyaluminosilicate ferric solution is 0.2 (wt)%;

[0033] 3. Collect the turbid w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com