Method for reducing special-shaped powder in high-alloying nickel-based alloy powder

A nickel-based alloy and alloying technology, applied in the field of reducing irregular powder in high-alloyed nickel-based alloy powder, can solve the problem of excessive irregular powder, reduce porosity, improve alloy fatigue life, and increase powder tap density Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

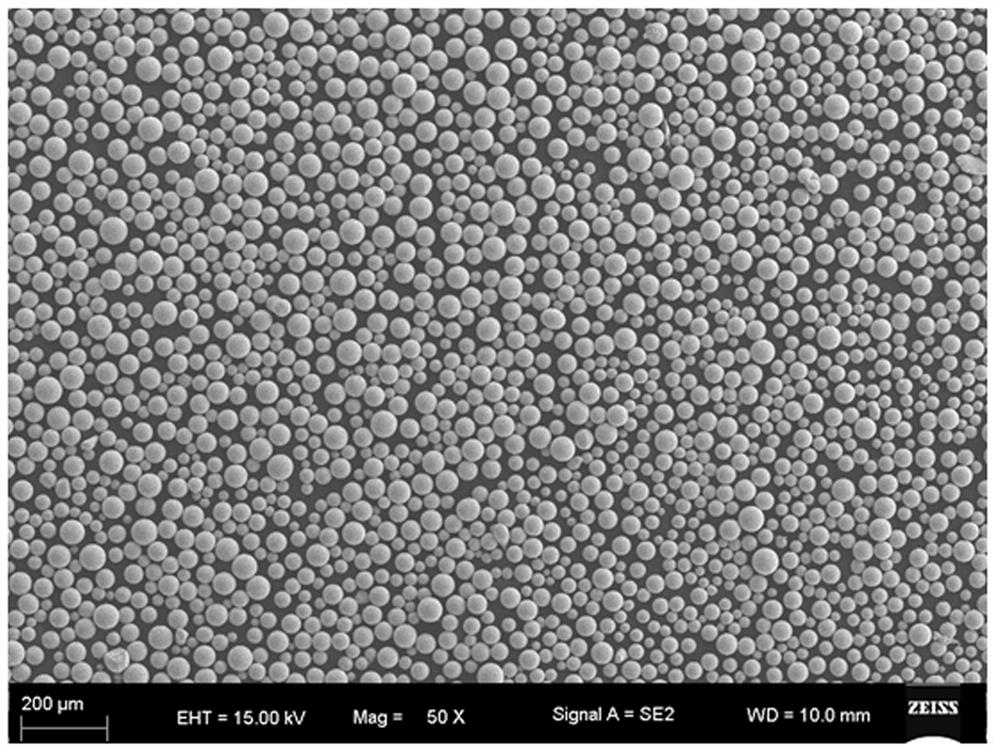

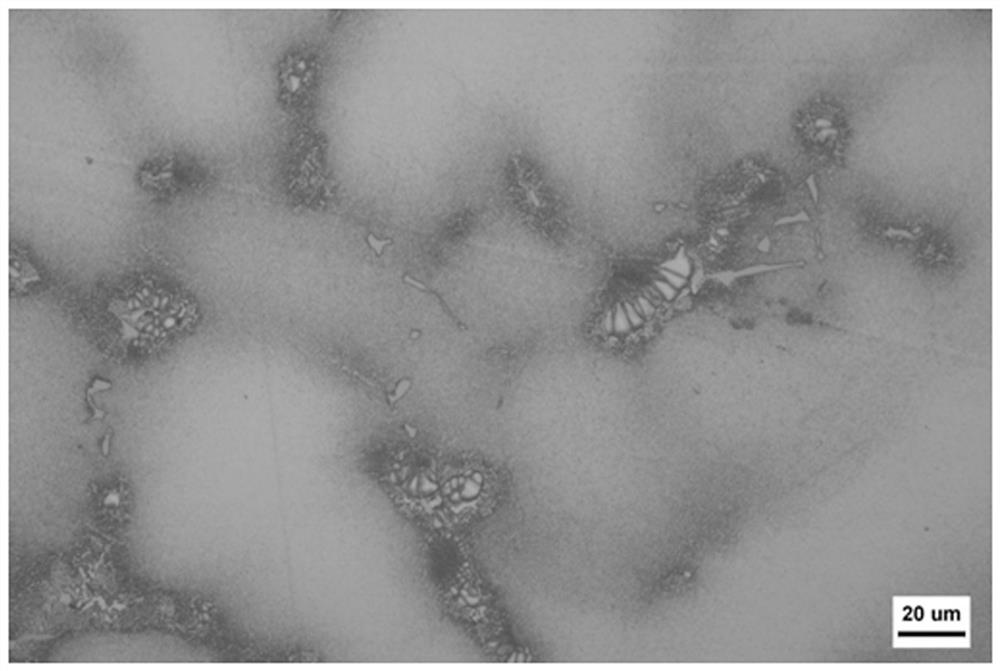

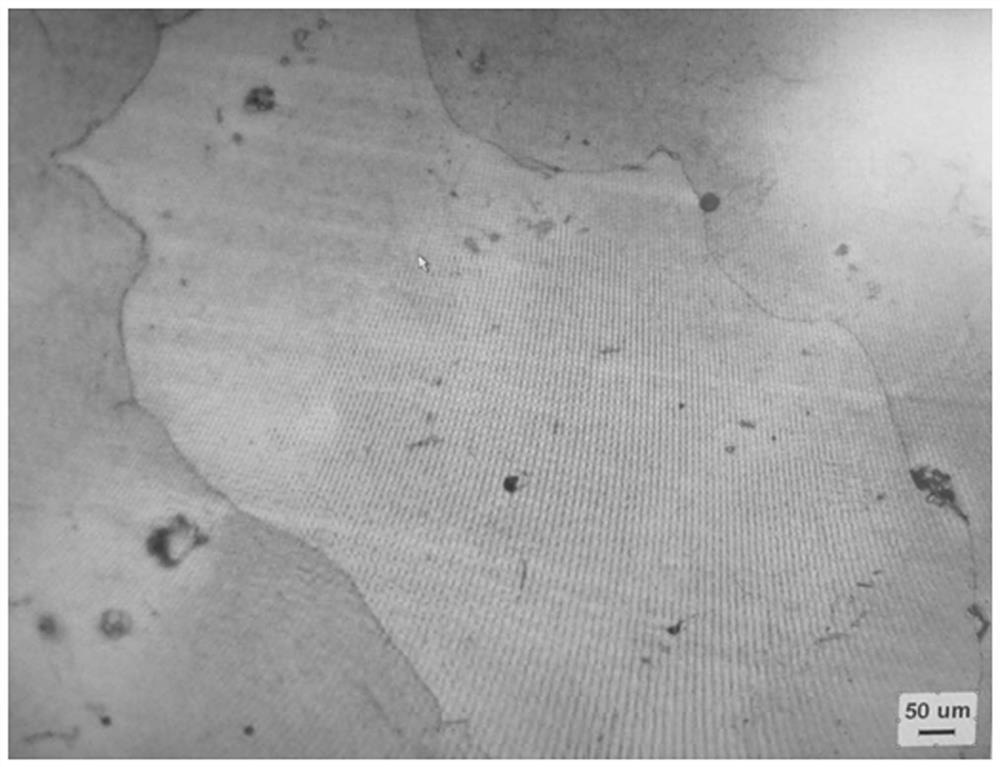

Image

Examples

Embodiment 1

[0037] A method of reducing the irregular powder in the high alloyed nickel-based alloy powder of the present invention is specifically implemented according to the following steps:

[0038] Step 1, preparing nickel-based superalloy rods through vacuum horizontal continuous casting and low temperature gradient cooling process;

[0039] Step 2, performing the first solid solution treatment on the nickel-based superalloy rod obtained in step 1; the first solid solution treatment is specifically: the solution temperature is 900°C, and the temperature is kept for 1 hour, and then cooled in an air atmosphere;

[0040] Step 3, performing a second solid solution treatment on the nickel-based superalloy rod obtained in step 2; the second solid solution treatment is specifically: the solid solution temperature is 1160 ° C, and after 4 hours of heat preservation, it is cooled in an air atmosphere;

[0041] Step 4, prepare the nickel-based superalloy rod obtained in step 2 into nickel-base...

Embodiment 2

[0044] A method of reducing the irregular powder in the high alloyed nickel-based alloy powder of the present invention is specifically implemented according to the following steps:

[0045] Step 1, preparing nickel-based superalloy rods through vacuum horizontal continuous casting and low temperature gradient cooling process;

[0046] Step 2, performing the first solid solution treatment on the nickel-based superalloy rod obtained in step 1; the first solid solution treatment is specifically: the solution temperature is 950°C, and the temperature is kept for 5 hours, and then cooled in an air atmosphere;

[0047] Step 3, performing a second solid solution treatment on the nickel-based superalloy rod obtained in step 2; the second solid solution treatment is specifically: the solution temperature is 1185° C., and the temperature is kept for 8 hours, and then cooled in an air atmosphere;

[0048] Step 4, prepare the nickel-based superalloy rod obtained in step 2 into nickel-bas...

Embodiment 3

[0051] A method of reducing the irregular powder in the high alloyed nickel-based alloy powder of the present invention is specifically implemented according to the following steps:

[0052] Step 1, preparing nickel-based superalloy rods through vacuum horizontal continuous casting and low temperature gradient cooling process;

[0053] Step 2, performing the first solid solution treatment on the nickel-based superalloy rod obtained in step 1; the first solid solution treatment is specifically: the solution temperature is 1000°C, and the temperature is kept for 6 hours, and then cooled in an air atmosphere;

[0054] Step 3, performing a second solid solution treatment on the nickel-based superalloy rod obtained in step 2; the second solid solution treatment is specifically: the solid solution temperature is 1210°C, and the temperature is kept for 12 hours, and then cooled in an air atmosphere;

[0055] Step 4, prepare the nickel-based superalloy rod obtained in step 2 into nick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com