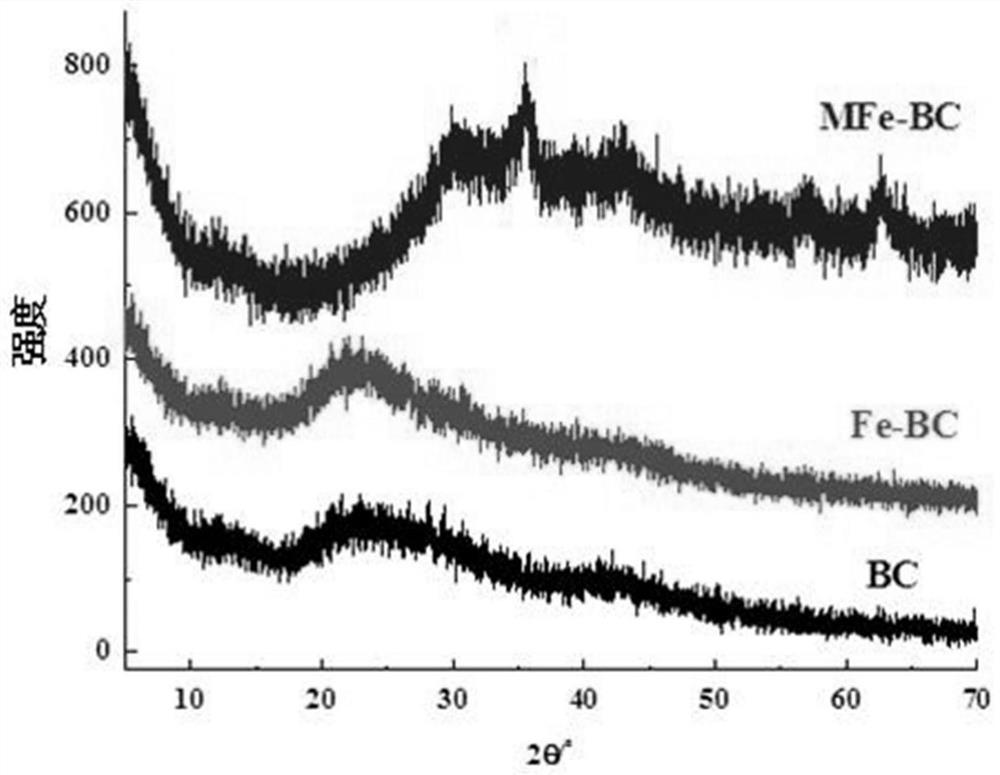

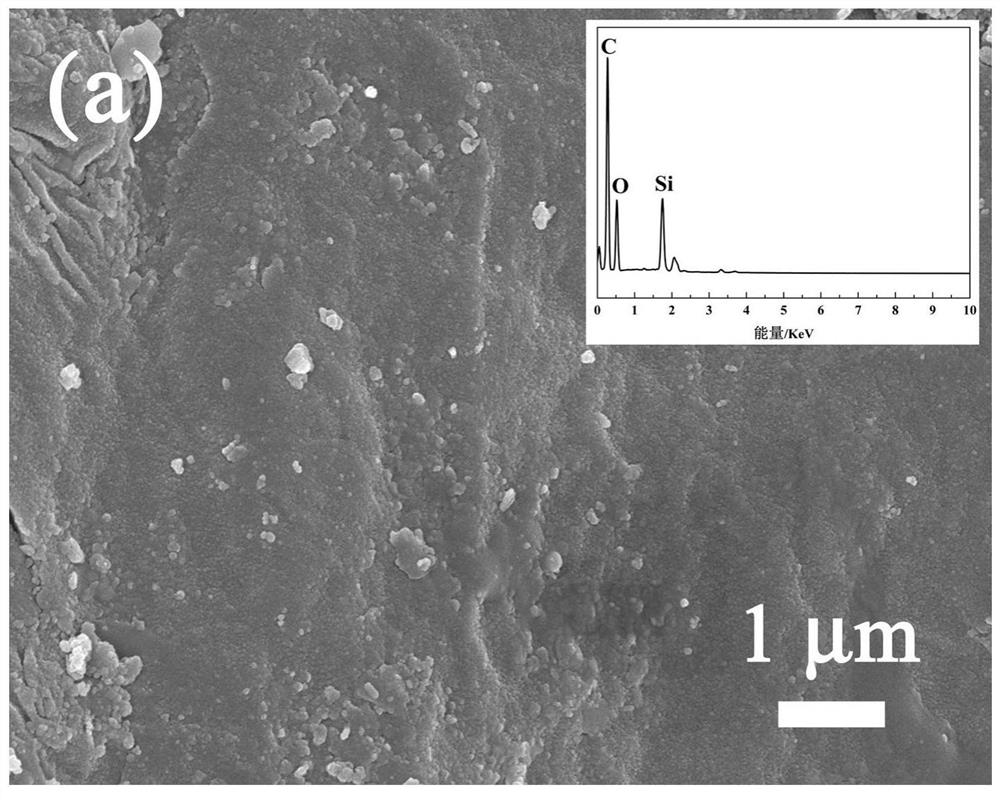

Magnetic Fe3O4/biochar adsorbent and application thereof

A biochar and adsorbent technology, applied in the direction of adsorption of water/sewage treatment, water/sludge/sewage treatment, alkali metal oxides/hydroxides, etc., can solve the problem of small number and types of functional groups and performance improvement of magnetic biochar No obvious problems affecting the morphology of biochar, etc., to achieve the effect of enriching the functional group structure, reducing the by-product ferric oxide, and improving the removal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preferred biochar preparation process is as follows: place the biomass material in an oxygen-barrier environment, rapidly heat up to 500-600°C at a rate of 20-30°C / min, heat-preserve and carbonize for 60-90min, grind it after natural cooling, and store it in a dry place; Further, the biomass material is placed in a CO2-filled 2 In the sealed pressure device, the pressure is raised so that the CO 2 Transform into a supercritical fluid and immerse the biomass material, then release the pressure, repeat the operation 3 to 5 times, and then soak the biomass material in water for 12 to 24 hours; further, the pressure increase rate is less than the pressure release rate, further, the pressure increase The rate is 0.1-0.5 MPa / min, and the pressure release rate is 2-3 MPa / min; the preferred biomass material is one of rice husk, crushed straw and sawdust.

[0040] The above magnetic Fe 3 o 4 / Application of biochar adsorbent to remove Cr from water. Preferably, the pH v...

Embodiment 1

[0043] A magnetic Fe 3 o 4 / biochar adsorbent, prepared by the following method:

[0044] (1) 0.10g (0.5mmol) FeCl 2 4H 2 O, 0.27g (1mmol) FeCl 3 ·6H 2 O was ultrasonically dissolved in a round bottom flask containing 20 mL of ethylene glycol;

[0045] (2) Disperse 0.3 g of biochar evenly in ethylene glycol with the assistance of ultrasonic waves, and then add 2 mL of 2 mol / L NaOH solution (0.16 g, 4 mmol);

[0046] (3) Place the round-bottomed flask in a microwave oven, open a hole at the top of the microwave oven, introduce a condensing reflux tube above the round-bottomed flask, and keep the continuous condensing reflux operation. The temperature of the condensate is 10 ° C; the frequency of the microwave is 2.45 × 10 9 Hz, the power of microwave is 640W; microwave reaction is 20min;

[0047] (4) After the reaction is completed, cool to room temperature, and the obtained black product is collected by centrifugation, washed 5 times with absolute ethanol, and vacuum-d...

Embodiment 2

[0051] A magnetic Fe 3 o 4 / biochar adsorbent, prepared by the following method:

[0052] (1) 0.10g (0.5mmol) FeCl 2 4H 2 O, 0.27g (0.8mmol) FeCl 3 ·6H 2 O was sonicated in a round bottom flask containing 20 mL of ethylene glycol;

[0053] (2) Disperse 0.25g of biochar evenly in the solution with the help of ultrasonic waves, and then add 2mL of 1.75mmol / L NaOH solution (0.14g, 3.5mmol);

[0054] (3) Place the round-bottomed flask in a microwave oven, open a hole on the top of the microwave oven, and introduce a condensation reflux tube above the round-bottomed flask. During the reaction, there is a continuous condensation and reflux operation. The temperature of the condensate is 10°C. The frequency is 2.0×10 9 Hz, the power of microwave is 500W; microwave reaction is 20min;

[0055] (4) Cool to room temperature after the reaction, the obtained black product is collected by centrifugation, washed 5 times with absolute ethanol, vacuum-dried at 60°C for 12h and sealed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com