Ceramic sewage treating method

A sewage treatment method and sewage technology, applied in the field of ceramic sewage treatment, can solve the problems of mud thixotropy, long running time of ball mill, and prolonging ball mill time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Follow the steps below for ceramic wastewater treatment:

[0021] S1. Separate several pools in the original sewage treatment system as special pools for ball milling water, and the sewage is injected into the pool through a special channel;

[0022] S2. Install a medium-sized water tank with a mixer on the special water channel, and install a tap water outlet on the lower half of the water tank;

[0023] S3. Add Al in the water tank 2 (SO 4 ) 3 And transformed into an aqueous solution with a concentration of 27wt%;

[0024] S4. When the sewage is poured into the ball mill special pool, turn on the faucet under the water tank to evenly add Al to the sewage flowing through 2 (SO 4 ) 3 Aqueous solution, adding 0.5L Al per ton of sewage 2 (SO 4 ) 3 Solution, make the pH value of sewage reach 6.0~6.5.

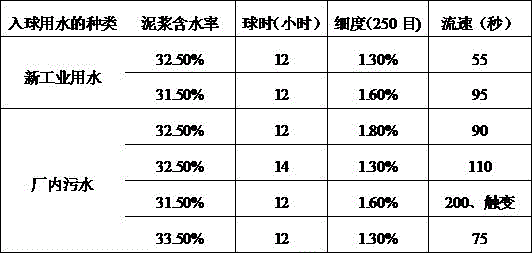

[0025] This treated sewage is used in the production of ball-milled ceramic slurry and compared with new industrial water, as shown in the following table:

[0026] Types of water ...

Embodiment 2

[0029] Follow the steps below for ceramic wastewater treatment:

[0030] S1. Separate several pools in the original sewage treatment system as special pools for ball milling water, and the sewage is injected into the pool through a special channel;

[0031] S2. Install a medium-sized water tank with a mixer on the special water channel, and install a tap water outlet on the lower half of the water tank;

[0032] S3. Add Al in the water tank 2 (SO 4 ) 3 It is transformed into an aqueous solution with a concentration of 25wt%;

[0033] S4. When the sewage is poured into the ball mill special pool, turn on the faucet under the water tank to evenly add Al to the sewage flowing through 2 (SO 4 ) 3 Aqueous solution, add 0.8L Al per ton of sewage 2 (SO 4 ) 3 Solution, make the pH value of sewage reach 6.0~6.5.

[0034] This treated sewage is used in the production of ball-milled ceramic slurry and compared with new industrial water, as shown in the following table:

[0035] Types of water u...

Embodiment 3

[0038] Follow the steps below for ceramic wastewater treatment:

[0039] S1. Separate several pools in the original sewage treatment system as special pools for ball milling water, and the sewage is injected into the pool through a special channel;

[0040] S2. Install a medium-sized water tank with a mixer on the special water channel, and install a tap water outlet on the lower half of the water tank;

[0041] S3. Add Al in the water tank 2 (SO 4 ) 3 It is transformed into an aqueous solution with a concentration of 25wt%;

[0042] S4. When the sewage is poured into the ball mill special pool, turn on the faucet under the water tank to evenly add Al to the sewage flowing through 2 (SO 4 ) 3 Aqueous solution, add 0.3L Al per ton of sewage 2 (SO 4 ) 3 Solution, make the pH value of sewage reach 6.0~6.5.

[0043] This treated sewage is used in the production of ball-milled ceramic slurry and compared with new industrial water, as shown in the following table:

[0044] Types of water u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com