Aroma slow-release layered material, preparation thereof and application of aroma slow-release layered material in heat-not-burn tobacco products

A heat-not-burn, tobacco product technology, applied in the preparation of tobacco, tobacco, application, etc., can solve the problems of poor uniformity of mouth-to-mouth release, poor smoking taste, easy loss of spices, etc., to improve the problem of burst release and improve sustained release performance, the effect of increasing the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] The gas phase adsorption preparation method of activated carbon@perfume complex is as follows:

[0090] This program investigated the immobilization and sustained release effects of coconut shell activated carbon, anthracite columnar activated carbon, fruit shell activated carbon, coal activated carbon, wood activated carbon and tar activated carbon on trimethylpyrazine (boiling point 171 °C). The specific implementation method is as follows:

[0091](1) Weigh an appropriate amount of anthracite columnar activated carbon for water purification, coconut shell activated carbon, fruit shell activated carbon, coal-based activated carbon, wood activated carbon, and tar activated carbon, grind them into powder respectively and pass through a 100-mesh sieve, boil with distilled water for 30 minutes, and cool After reaching room temperature, wash with distilled water for 2 to 3 times, boil again for 30 minutes, repeat the same operation as before, and then dry in a constant tem...

Embodiment 2

[0101] The liquid-phase adsorption preparation method of activated carbon@perfume complex is as follows:

[0102] In order to further increase the adsorption capacity of the fragrance raw material, on the basis of Example 1, this example changed the gas-phase adsorption to liquid-phase adsorption, the temperature of the adsorption process was 35°C, and the weight was weighed after 24 hours. The adsorption capacity of activated carbon is shown in Table 2 shown.

[0103] Table 2 Adsorption capacity of trimethylpyrazine by different types of activated carbon under liquid phase adsorption conditions

[0104]

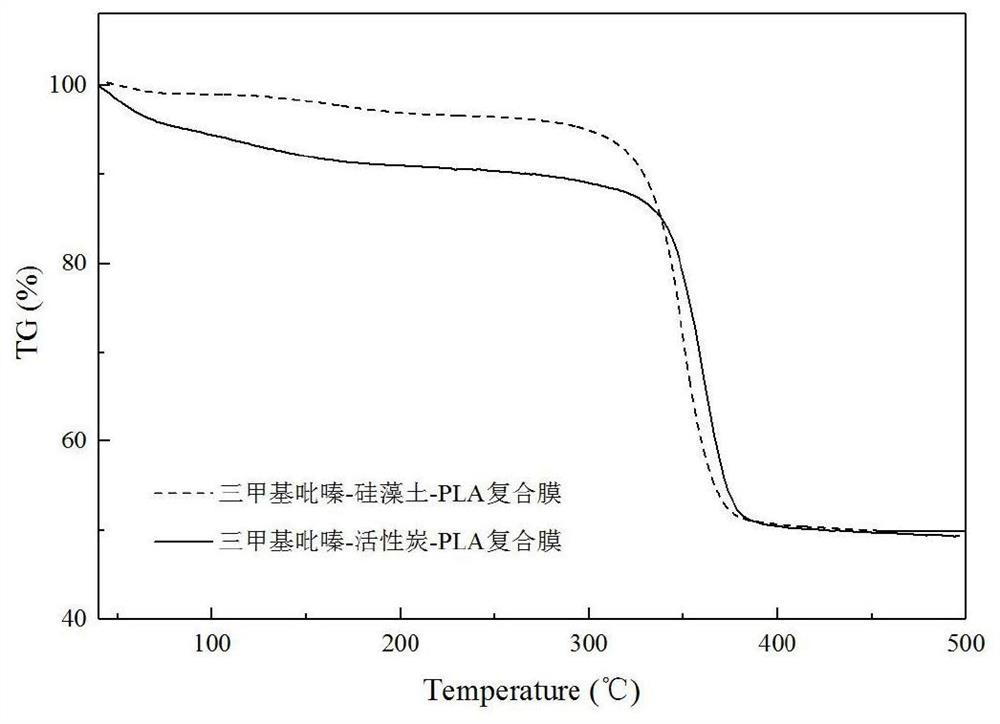

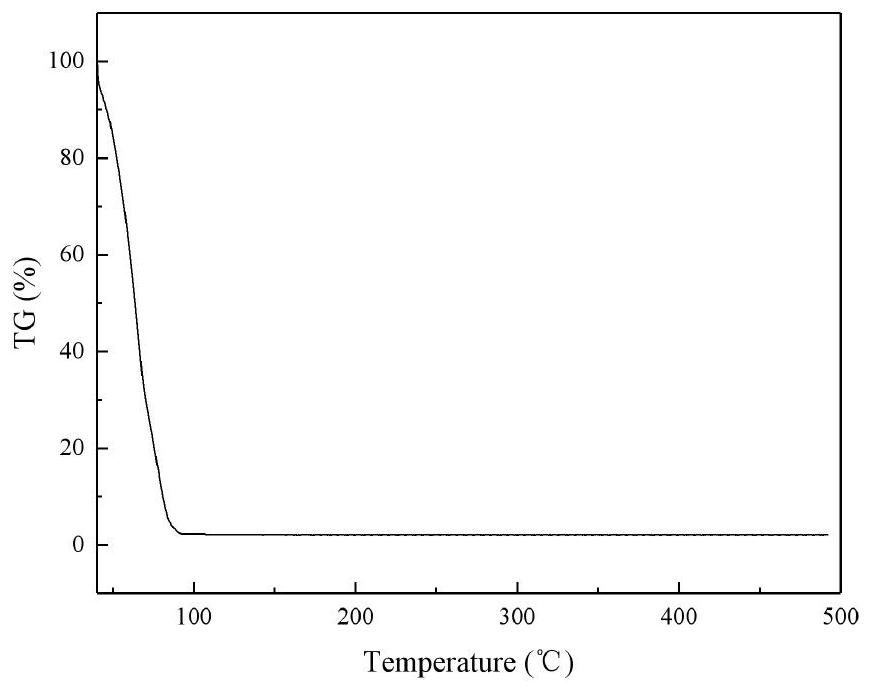

[0105] Comparing Table 1 and Table 2, it can be seen that the amount of fragrance adsorption by liquid phase adsorption method is larger than that of gas phase adsorption method, and by figure 2 It can be seen that the adsorption capacity of activated carbon to trimethylpyrazine is basically constant within 7 days, and the adsorption equilibrium has been reached, indica...

Embodiment 3

[0116] In this program, the paper substrate B is used as the coating substrate, the activated carbon (iodine value 1000mg / g) is used as the adsorbent, and the methyl cellulose is used as the membrane material to prepare a high-volatility fragrance slow-release material. Immobilization and sustained release effects of esters. The specific implementation method is as follows:

[0117] (1) Manufacture of paper base material B: using northern wood pulp and smoke powder as raw materials, paper base material B is produced by papermaking sheet production method, and its surface is loaded with 20% tobacco extract by dip coating, so that Its color is closer to the natural color of tobacco;

[0118] (2) Weigh 1g of the fruit shell activated carbon after the ash treatment, adopt the liquid phase adsorption method to carry out the adsorption test of ethyl propionate, add 1g of ethyl propionate dropwise to the activated carbon, and mix well (the adsorption temperature is 35 ℃, and the tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption temperature | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com