Power battery pack thermal management system based on immersed boiling heat transfer

A technology for power battery packs and thermal management systems, applied to secondary batteries, circuits, electrical components, etc., can solve the problems of increasing space requirements, weight and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

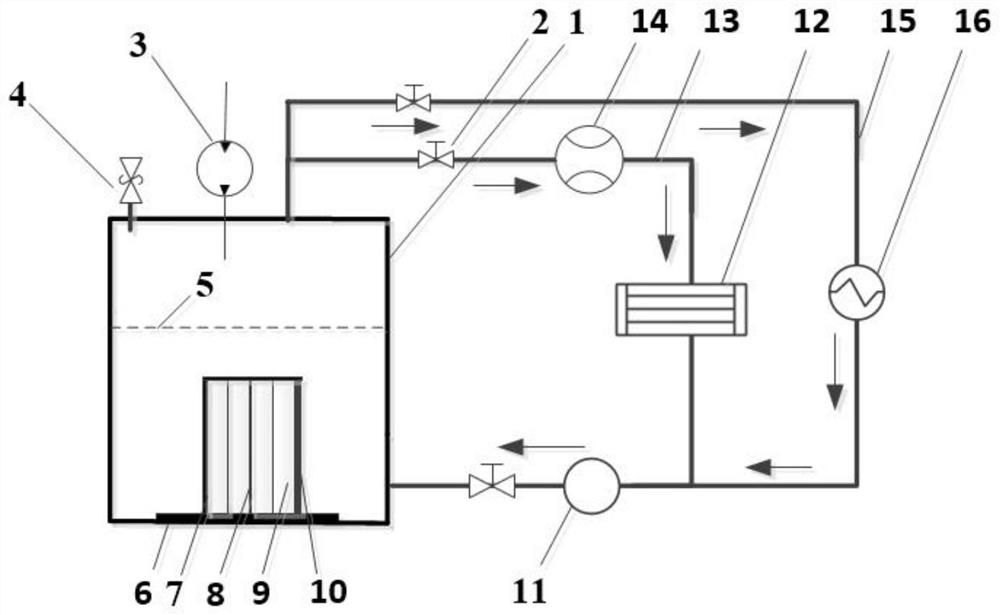

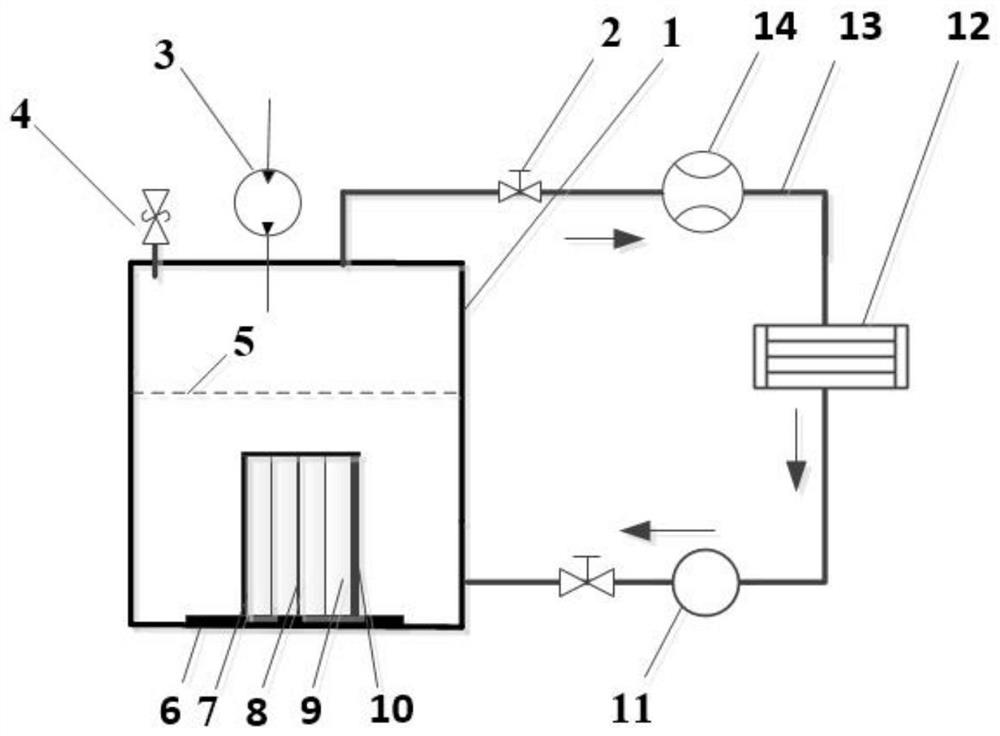

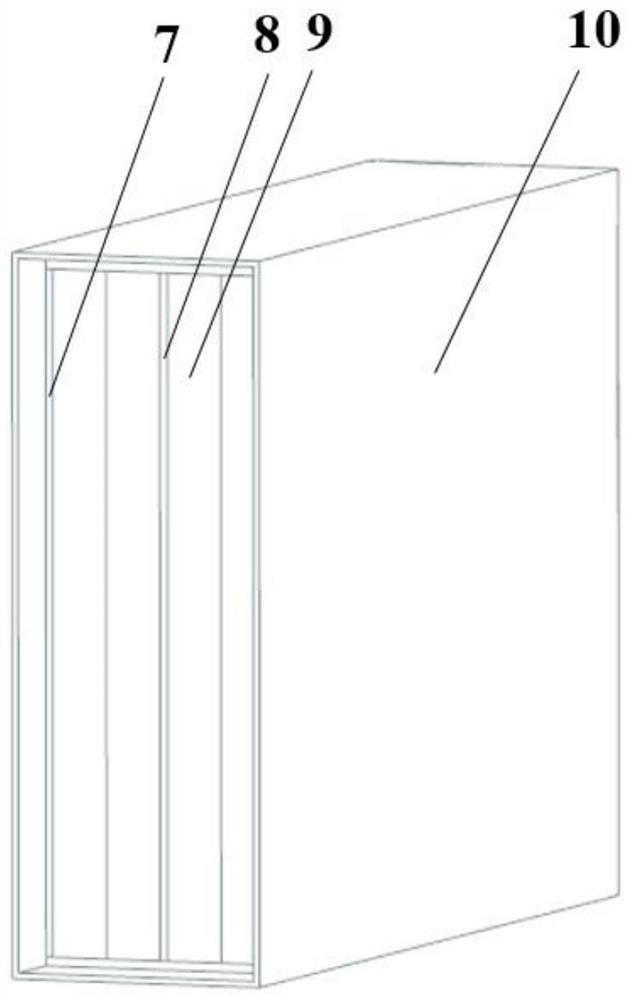

[0019] The present invention will be further explained below in conjunction with the accompanying drawings.

[0020] Such as figure 1 , image 3 As shown, a power battery pack thermal management system based on submerged boiling heat transfer includes a power battery 9 arranged inside an aluminum barrel 10, and a heat insulation pad 8 made of airgel is arranged between each piece of power battery 9 . Foam 7 is arranged between the power battery 9 and the aluminum barrel 10 , and the power battery 9 together with the aluminum barrel 10 is immersed in the low-boiling-point working medium 5 in the steel sealed tank 1 . The bottom of the sealing groove 1 is provided with a PTC heating film 6, and a vacuum pump 3 is used to vacuumize the sealing groove 1. Among them, the low-boiling-point working medium has a gas point less than 40°C, preferably an electronic fluorinated liquid, specifically hydrofluoroether, liquid ammonia, liquid propane, and the like. When thermal runaway occ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com