Light decoration and heat preservation integrated external wall panel

A light-weight technology for exterior wall panels, applied in the field of building wall panels, can solve problems such as uncontrollable costs, cold bridges, and weak adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

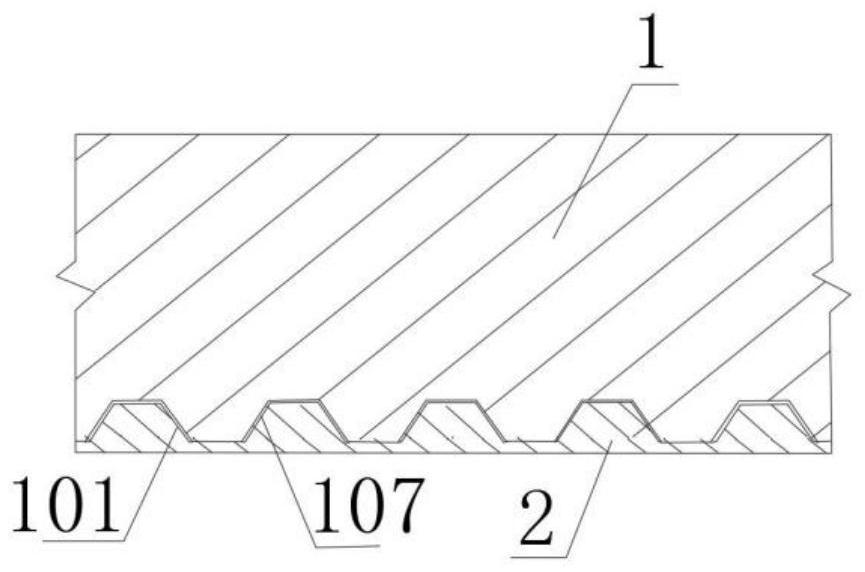

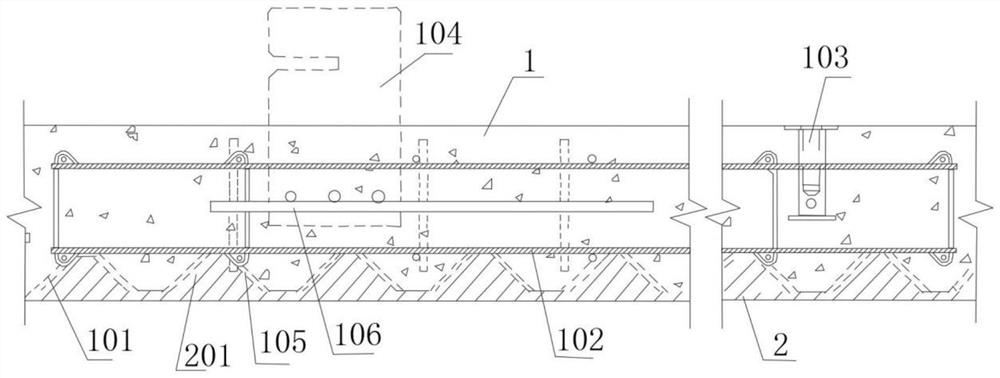

[0041] see Figure 1-2 As shown, a light-weight decorative and thermal insulation integrated exterior wall panel of the present invention includes a poured foamed concrete thermal insulation layer 1 and an exterior wall decorative surface layer 2 poured on the outside of the foamed concrete thermal insulation layer 1;

[0042] The contact surface between the foamed concrete insulation layer 1 and the exterior wall decorative surface layer 2 is a structure of open grooves 101 evenly distributed and misplaced, and the contact part between the exterior wall decorative surface layer 2 and the foamed concrete insulation layer 1 is corresponding to the open groove 101 The protruding structure 201 opened in the dislocation; the steel wire mesh 105 attached along the forming surface is arranged between the opening groove 101 and the protruding structure 201;

[0043] The foamed concrete insulation layer 1 is prepared from cement, ceramsite, mineral admixture, water, fiber filaments, f...

specific Embodiment 2

[0057] The difference of this specific embodiment with respect to specific embodiment 1 is:

[0058] Wherein, the material of foamed concrete insulation layer 1 contains the proportioning of building slag:

[0059]

[0060] Among them, the foaming agent uses 1:25 times concentrated rosin thermal polymer foaming liquid.

[0061] Among them, the ceramsite adopts a bulk density of 400kg / m 3 Ceramsite with closed cell structure.

[0062] Among them, the bulk density of the foamed concrete insulation layer 1 is 900kg / m 3 .

[0063] Wherein, the thickness of the foamed concrete insulation layer 1 is 200 mm.

[0064] Wherein, the opening groove 101 adopts a triangular shape, and the shape of the protruding structure 201 matches the opening groove 101 correspondingly.

[0065] Preparation:

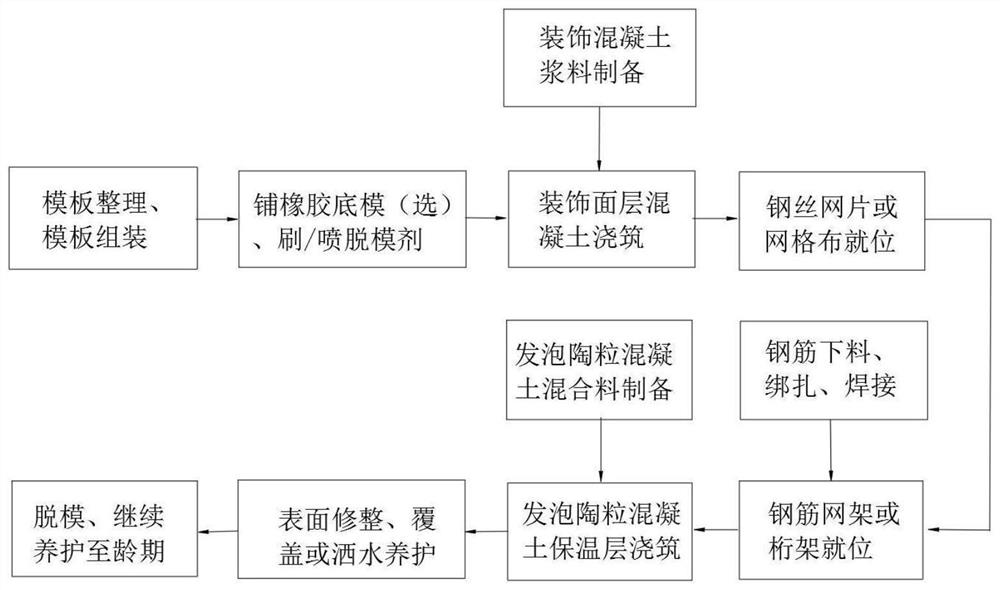

[0066] Such as image 3 As shown, the production process of the light-weight decorative thermal insulation integrated exterior wall panel of the present invention, that is, its preparati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com