Feed pipe for preventing erosion of die-casting material barrel

A technology for preventing erosion and feeding tube, which is applied to the feeding tube structure to avoid erosion of the die-casting barrel, the feeding tube for the anti-erosion of the die-casting barrel, and the field of the feeding tube structure, which can solve the erosion force of the splitter plate. Large, barrel wear, large drop and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

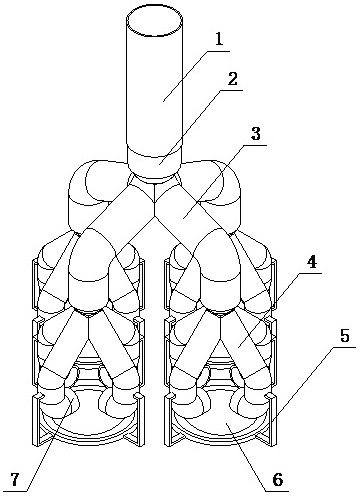

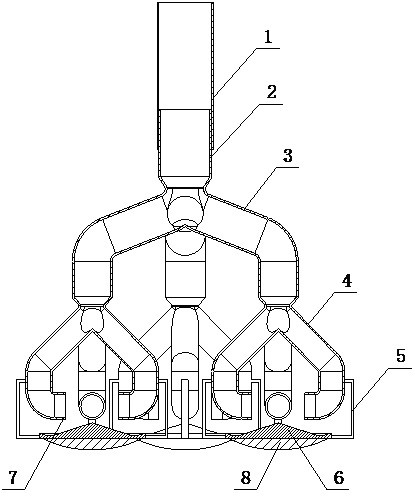

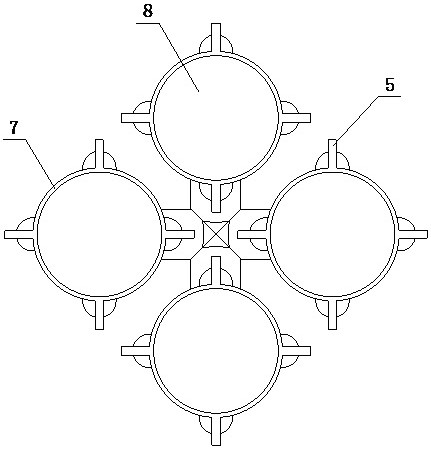

[0017] An anti-erosion feed pipe for a die-casting barrel of the present invention is realized in the following way: a feed pipe for an anti-erosion die-casting barrel of the present invention consists of a fixed pipe (1), a main infusion tube (2), and an auxiliary infusion tube (3), a branch infusion tube (4), a fixed frame (5), a splitter plate (6), a liquid outlet tube (7), a floating plate (8), a conical inclined surface (9) and a buffer lifting surface (10), One end of the main infusion tube (2) is connected to the fixed tube (1) and communicated with each other, the other end of the main infusion tube (2) is provided with a main pipeline assembly, and one end of a plurality of auxiliary infusion tubes (3) Placed on the main pipeline assembly, the other end of the auxiliary infusion tube (3) first extends obliquely downward, and then bends vertically downward, and the other end of the auxiliary infusion tube (3) is provided with an auxiliary pipeline assembly One end of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com