A method for suppressing photocorrosion of bismuth oxyhalide

A bismuth oxyhalide and photocorrosion technology, applied in the field of photocatalytic materials, can solve the problems of easy photocorrosion, performance degradation, hindering use, etc., and achieve the effects of excellent photocorrosion resistance, stable catalyst, and easy recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

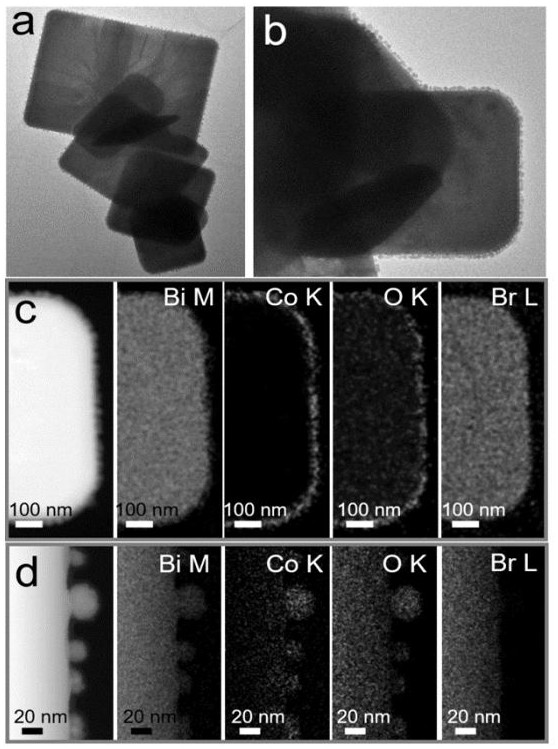

Image

Examples

Embodiment 1

[0025] 1) Preparation of bismuth oxybromide (BiOBr) nanosheets: 1 mmol bismuth nitrate pentahydrate (Bi(NO 3 ) 3 ·5H 2 O) Dissolve in 30 mL ethylene glycol solution and transfer to a syringe with a 50 mL range, then inject slowly at a speed of 2 mL / min, drop into 30 mL aqueous solution containing 3 mmol potassium bromide (KBr), immediately There will be a white precipitate. After dripping, stir for 30 min, centrifuge and wash the product three times with water, transfer to 30 mL of aqueous solution with pH 1, and finally put it into a 50 mL hydrothermal kettle, and heat at 140°C for 8 hours. After the reaction is completed, centrifuge, wash with water and ethanol for several times, and place in a 60°C oven to dry overnight to obtain bismuth oxybromide (BiOBr) nanosheets.

[0026] 2) Preparation of cobalt nitrate hexahydrate aqueous solution: Dissolve 1 g of cobalt nitrate hexahydrate solid in 50 mL of water to obtain.

[0027] 3) Preparation of bismuth cobalt trioxide / bism...

Embodiment 2

[0030] 1) Preparation of bismuth oxychloride (BiOCl) nanosheets: 1 mmol bismuth nitrate pentahydrate (Bi(NO 3 ) 3 ·5H 2 O) Dissolve in 30 mL ethylene glycol solution and transfer to a syringe with a 50 mL range, then inject slowly at a speed of 2 mL / min, drop into 30 mL aqueous solution containing 3 mmol potassium chloride (KCl), immediately There will be a white precipitate. After dripping, stir for 30 min, centrifuge and wash the product three times with water, transfer to 30 mL of aqueous solution with pH 1, and finally put it into a 50 mL hydrothermal kettle, and heat it at 140°C for 4 hours. After the reaction is completed, centrifuge, wash with water and ethanol for several times, and place in a 60°C oven to dry overnight to obtain bismuth oxychloride (BiOCl) nanosheets.

[0031] 2) Preparation of cobalt nitrate hexahydrate aqueous solution: Dissolve 1 g of cobalt nitrate hexahydrate solid in 50 mL of water to obtain.

[0032] 3) Preparation of bismuth cobalt trioxid...

Embodiment 3

[0035] 1) Preparation of bismuth oxyiodide (BiOI) nanosheets: 1 mmol bismuth nitrate pentahydrate (Bi(NO 3 ) 3 ·5H 2 O) Dissolved in 30 mL of ethylene glycol solution and transferred to a syringe with a 50 mL range, then injected slowly at a rate of 2 mL / min, dripping into 30 mL of an aqueous solution containing 3 mmol of potassium iodide (KI), there will be White precipitate. After dripping, stir for 30 min, centrifuge and wash the product three times with water, transfer to 30 mL of aqueous solution with a pH of 1, and finally put it into a 50 mL hydrothermal kettle, and heat it at 160°C for 10 h. After the reaction is completed, centrifuge, wash with water and ethanol several times, and place in a 60°C oven to dry overnight to obtain bismuth oxyiodide (BiOI) nanosheets.

[0036] 2) Preparation of cobalt nitrate hexahydrate aqueous solution: Dissolve 1 g of cobalt nitrate hexahydrate solid in 50 mL of water to obtain.

[0037] 3) Preparation of bismuth cobalt trioxide / bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com