Gelled aerosol product and gel forming kit

A gelation and aerosol technology, applied in the direction of cosmetic preparations, cosmetics, dressing preparations, etc., can solve the problems of not being easy to use, beauty ingredients remaining on the skin, etc., and achieve the effect of fast gelation and inhibition of dehydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

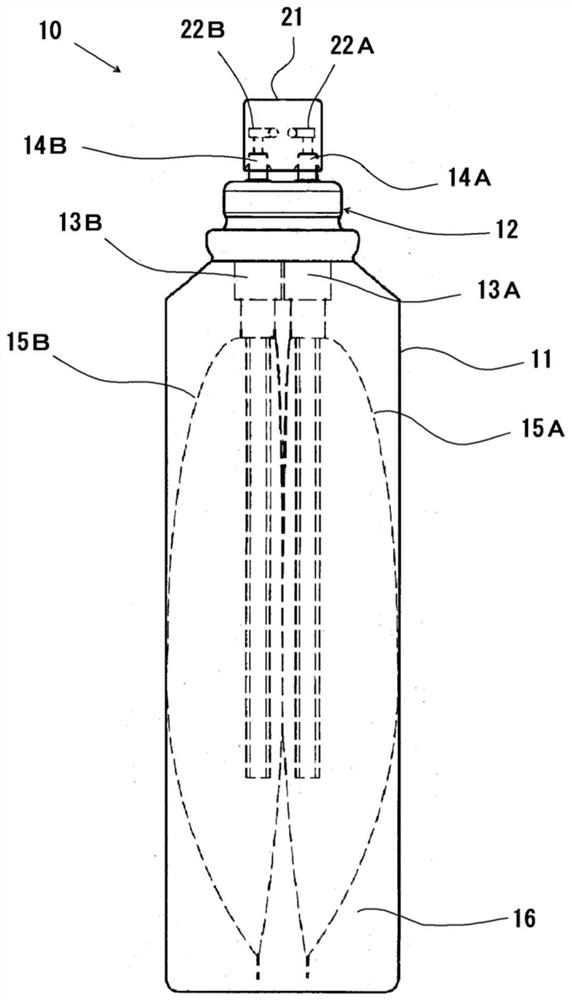

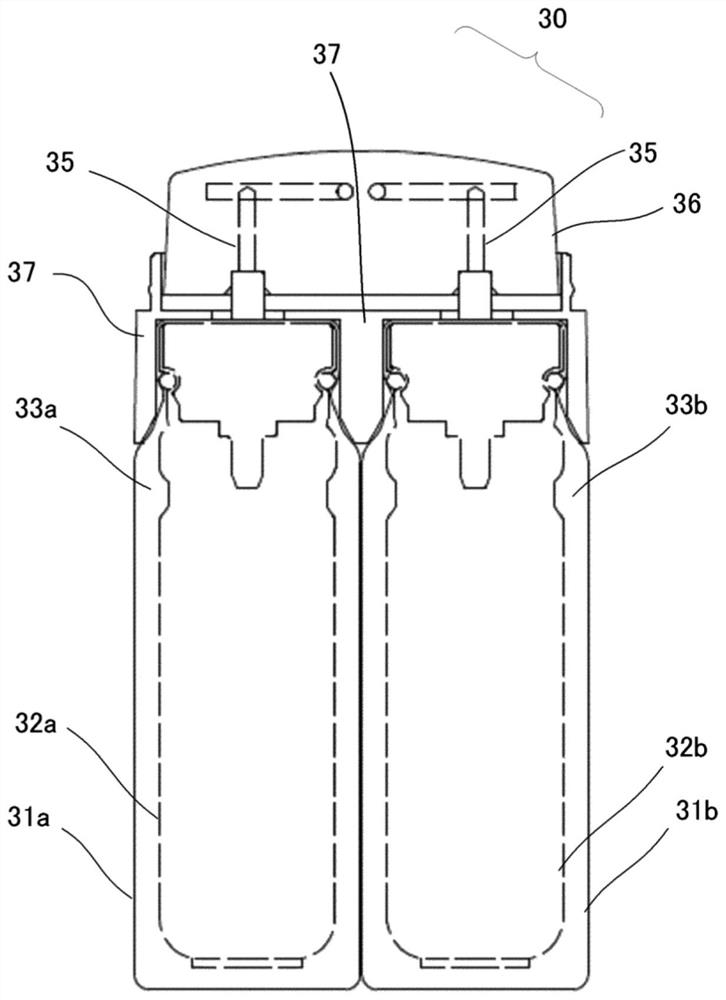

Image

Examples

Embodiment 1

[0089]

[0090] (Preparation of the first solution)

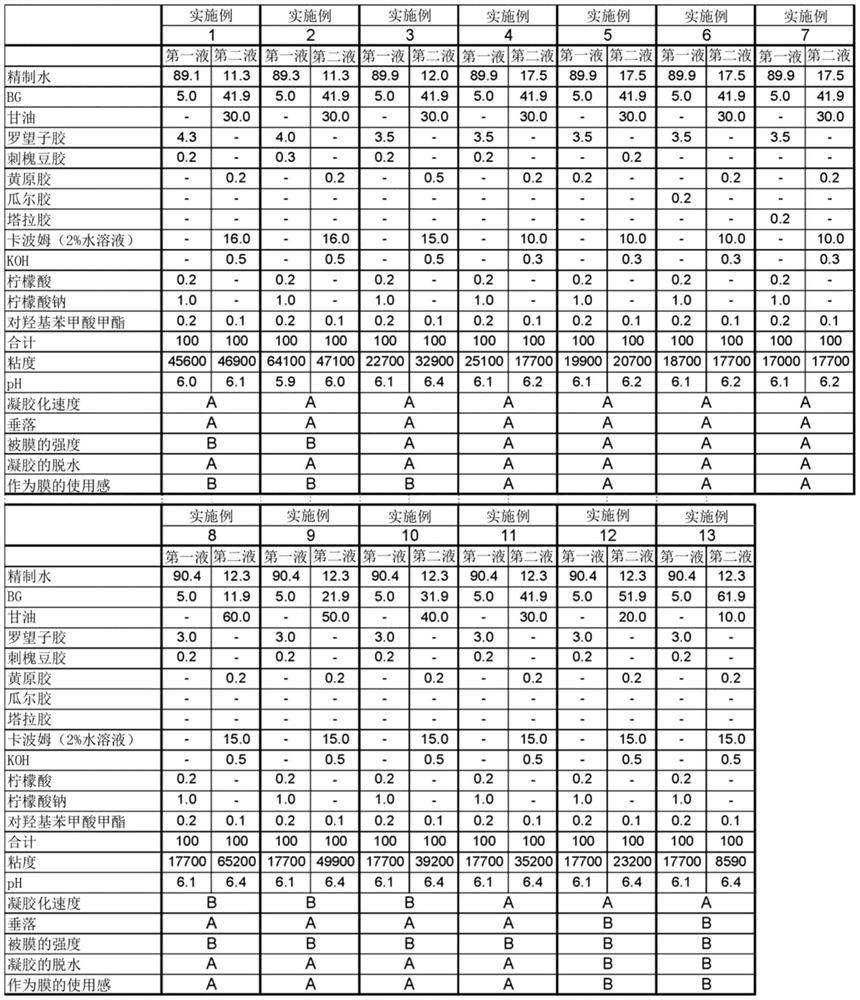

[0091] The formulation was carried out as described in Table 1. A dispersion was prepared by adding tamarind gum, locust bean gum, and methylparaben to 1,3-butanediol (BG). The dispersion liquid was added while stirring water, and after heating in a warm bath to 80° C., it was further stirred for 30 minutes to obtain a uniform paste liquid. After adding 10% citric acid aqueous solution and 10% sodium citrate aqueous solution to adjust to predetermined pH, it cooled and obtained the 1st liquid.

[0092] (Preparation of the second solution)

[0093] The formulation was carried out as described in Table 1. Xanthan gum and methylparaben were added to a part of BG to prepare a dispersion. While stirring water, this dispersion liquid and carboxyvinyl polymer (hereinafter referred to as carbomer) (2% aqueous solution) were added, and stirred for 30 minutes to obtain a uniform paste liquid. Glycerin and the remaining BG were...

Embodiment 2~13

[0132] In Example 1, the formulations of the first liquid and the second liquid were changed to those described in Table 1, and an aerosol product was obtained. Table 1 shows the evaluation results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com