High-voltage megavolt coaxial-flat plate hybrid low-inductance pulse capacitor

A pulse capacitor and hybrid technology, applied in the field of capacitors, can solve the problems of high withstand voltage and difficult to meet low inductance, etc., to achieve the effect of increasing the working voltage, improving the output pulse voltage index, and easily adjusting the size of the capacitor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

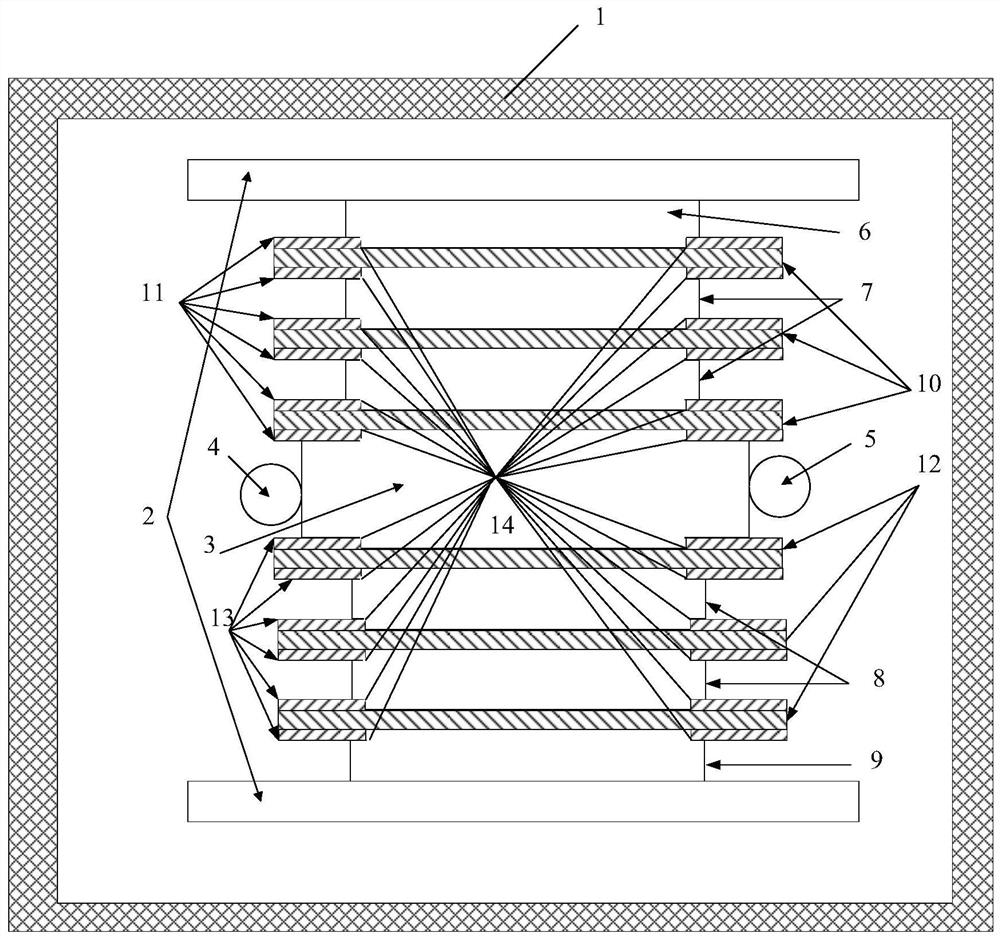

[0047] This embodiment provides a specific structure of a high-voltage megavolt coaxial-plate hybrid low-inductance pulse capacitor, such as figure 1 As shown, it includes an insulating cavity 1, a capacitor outer cylinder 2, a first low-voltage electrode assembly, a high-voltage electrode assembly, and a second low-voltage electrode assembly;

[0048] The capacitor outer cylinder 2 is arranged in the insulating cavity 1, and the insulating cavity 1 is filled with 1.6Mpa SF 6 gas;

[0049] The first low-voltage electrode assembly, the high-voltage electrode assembly, and the second low-voltage electrode assembly are arranged coaxially in the capacitor outer cylinder 2 in sequence along the radial direction;

[0050] The high-voltage electrode assembly includes a magnetic pressure high-voltage electrode 3, a shielding ball 4 at the high-voltage input end, and a shielding ball 5 at the high-voltage output end;

[0051] Both the shielding ball 4 at the high-voltage input end an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com