Layered gradient porous material sweating cooling structure and aircraft

A sweat cooling, gradient porous technology, applied in instruments, special data processing applications, electrical digital data processing, etc., can solve the problems of high cost, poor thermal protection effect, uneven heat dissipation, etc., achieve low cost, overcome local hot spots effect, good thermal protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

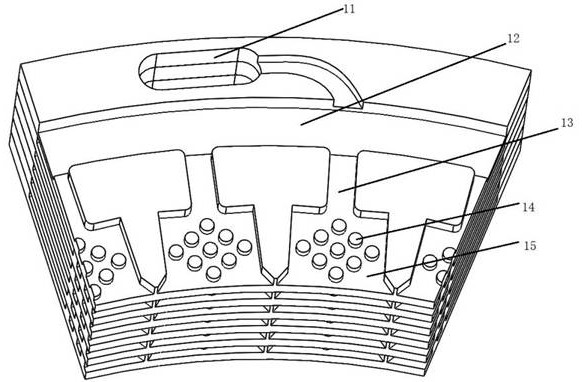

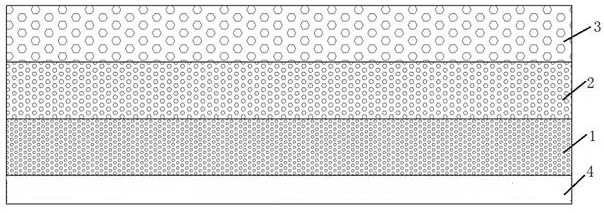

[0041] Such as Figure 1 to Figure 3 As shown, a layered gradient porous material sweat cooling structure includes N layers of porous material layers 10, a cooling cavity 4 arranged on one side of the porous material layer 10, and a coolant supply unit 5 is arranged in the cooling cavity 4, so The coolant supply unit 5 is used to supply the coolant to the cooling cavity 4, and the porosity of the porous material layer 10 decreases layer by layer along the direction close to the cooling cavity 4, wherein N is an integer, and N≥2.

[0042] The present invention draws lessons from the high-friction characteristics of the lamination cooling structure control channel and the low-friction characteristics of the diffuse flow channel. The N-layer porous material layer 10 adopts porous material, and the porosity of the porous material layer 10 is sequentially pressed along the direction close to the cooling chamber 4. The layers are reduced, the porosity of the layer of porous material...

Embodiment 2

[0050] Such as Figure 1 to Figure 3 As shown, as a further optimization of Embodiment 1, this embodiment includes all the technical features of Embodiment 1. In addition, this embodiment also includes the following technical features:

[0051] As a preferred technical solution, the coolant supplied by the coolant supply unit 5 is a gaseous or liquid substance.

[0052] The gaseous or liquid coolant has good flow performance, which is conducive to the adequacy of heat exchange, further enhances the uniformity of heat exchange and temperature stability, and is convenient for storage.

[0053] As a preferred technical solution, the material of the N-layer porous material layer 10 is ceramic or stainless steel.

[0054] Ceramic or stainless steel has a high melting point, and it is easy to choose to make a porous material structure, which is convenient for procurement and maintenance.

[0055] As a preferred technical solution, the porosity of the N-layer porous material layer ...

Embodiment 3

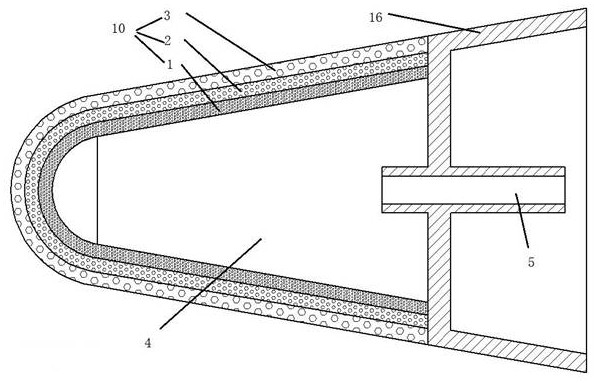

[0061] Such as Figure 1 to Figure 3 As shown, this embodiment provides an aircraft, including the above-mentioned layered gradient porous material sweating cooling structure.

[0062] The layered gradient porous material sweating cooling structure of the aircraft draws lessons from the high frictional resistance characteristics of the laminated sweating cooling structure control channel and the low frictional resistance characteristic of the diffuse flow channel. The N-layer porous material layer 10 adopts porous material, and the porosity of the porous material layer 10 is along The direction close to the cooling chamber 4 decreases successively according to the layers. The layer of the porous material layer 10 close to the cooling chamber 4 has a small porosity and a large proportion of flow resistance, which is similar to the control channel of the laminate sweating cooling structure; the porous material layer 10 is far away from the cooling chamber. The layer porosity of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com