Self-operated type bevel valve

A bevel valve, self-operated technology, applied in the field of self-operated bevel valve, can solve the problems of constant and easy to change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

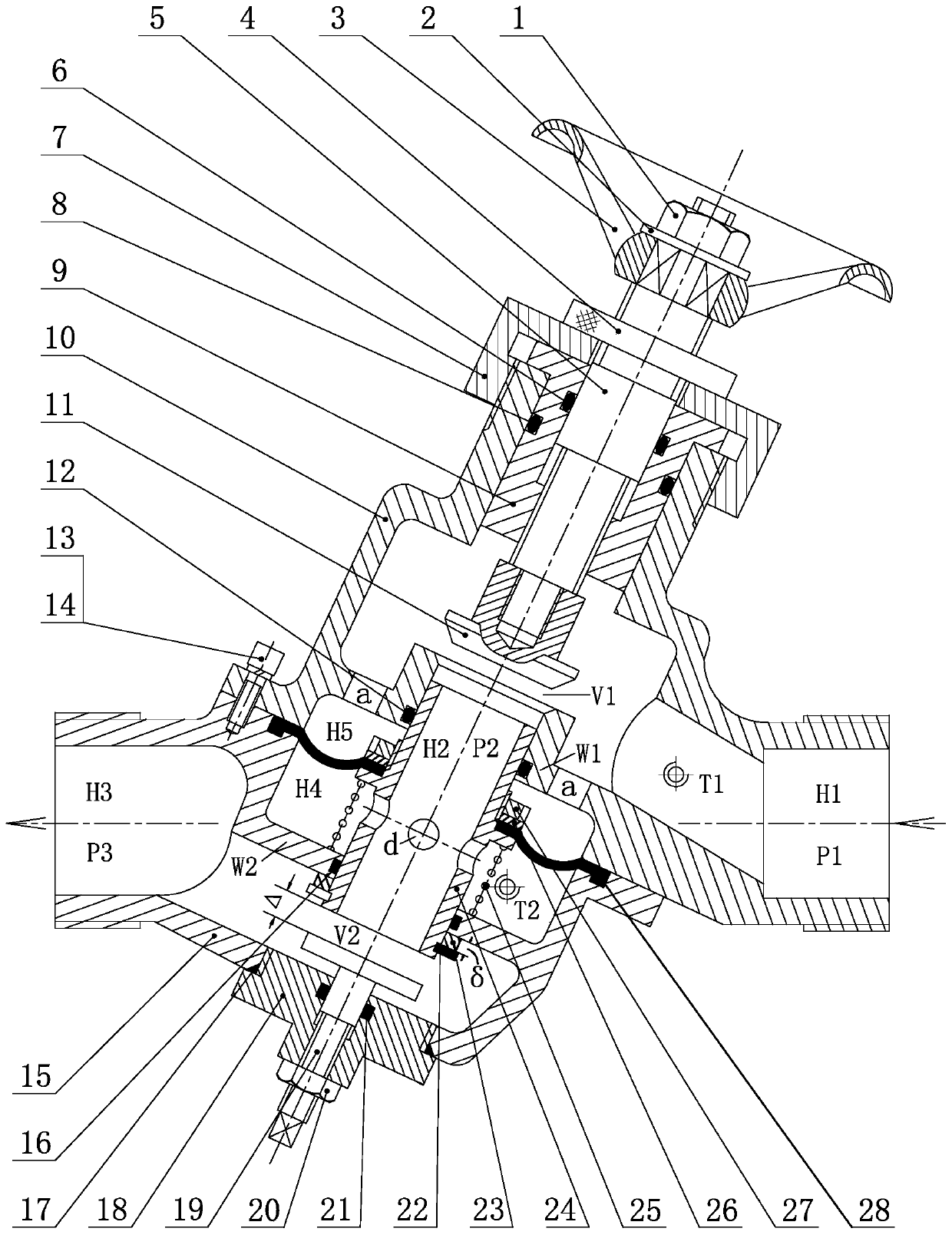

[0015] Through the following examples, combined with the attached figure 1 The specific implementation manners of the present invention will be further described.

[0016] For the longitudinal sectional view of this patent, see figure 1 , including a regulating valve and a constant pressure reducing valve, the regulating valve is set in the cavity of the upper valve body 10, the differential pressure reducing valve is set in the cavity of the lower valve body 15, the lower flange of the upper valve body 10 and the upper flange of the lower valve body 15 Flange is connected as a whole with some auxiliary screws 13, spring washers 14, and the center line of two valve bodies after connecting is on the same axis, and has certain oblique angle with the horizontal axis of inlet and outlet. The lower end of the upper valve body 10 is a flange; the inner hole on the rightward protruding part is a water inlet hole; the upper part is a stepped cylinder with a diameter that is small at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com