Compatibility optimization design method for coating of small complex profile part

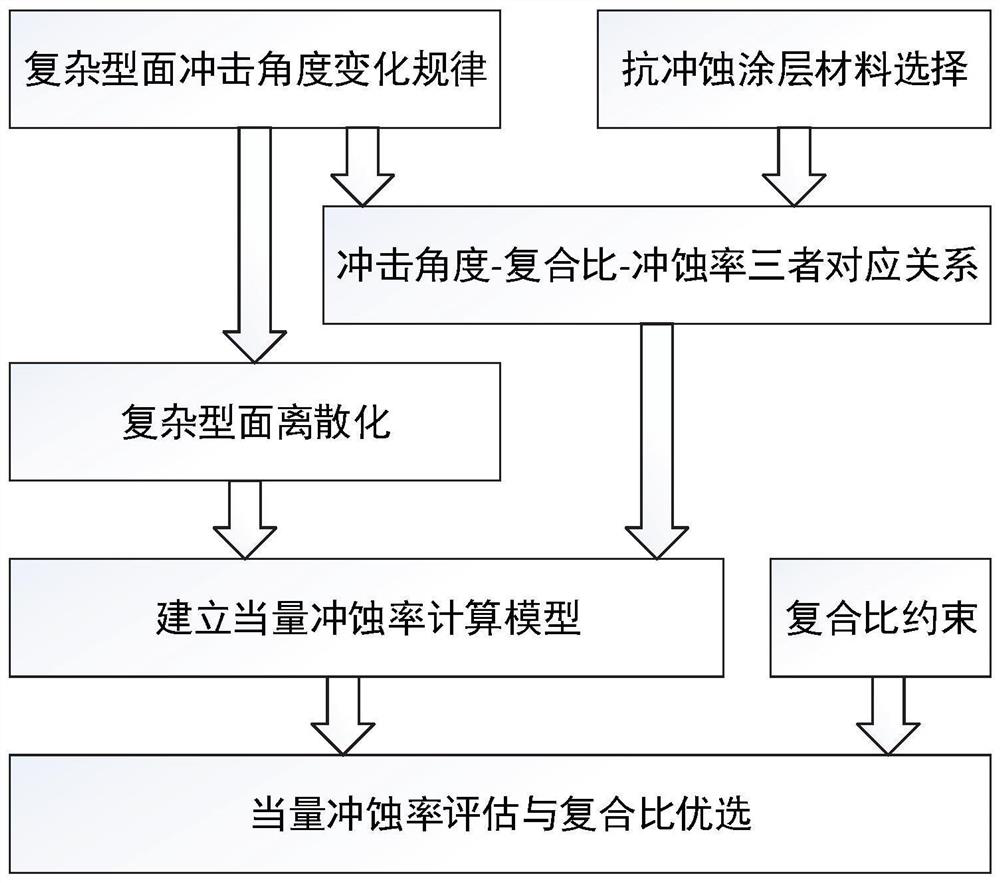

A technology for complex profile and optimized design, applied in design optimization/simulation, computer-aided design, calculation, etc., can solve the problems of large spraying radius and inability to realize complex profile material compatibility point-by-point deposition, etc. The method is simple and easy Promote and improve the effect of anti-erosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061]Take a certain type of small complex surface blade (the matrix material is FV520B) in a high temperature environment, and the air solid two-phase flow erosion is worn, and the metal ceramic CR is prepared on the surface.3C2-Nicr coating (with "NiCr" in the composite coating, the quality of the composite coating, specifically includes the following steps:

[0062]Step 1: The technical solution described in the design method of the complex facer-cutting member cutting gradient heat spray coating coating is obtained by the technical solution described in the surface of the complex facework member and the impact angle of the erosion particle, acquisition impact angle The relationship with the leaf polar coordinates α = g (θ).

[0063]Where θ is the variable of the blade position, α is an impact angle.

[0064]Step 2: According to the service conditions, the coating needs to have anti-erosion wear and high temperature resistance, select the metal ceramic coating Cr.3C2-NICR.

[0065]Step 3: Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com