Design and processing method of a lamp reflector

A design method and reflector technology, applied in reflectors, lighting and heating equipment, components of lighting devices, etc., can solve the problems of different bacterial inactivation rates, low energy utilization rate, uneven illumination distribution, etc. The effect of improving energy utilization, flexible method and simple processing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0060] Select the UV germicidal lamp as the lamp tube described in the reflector design:

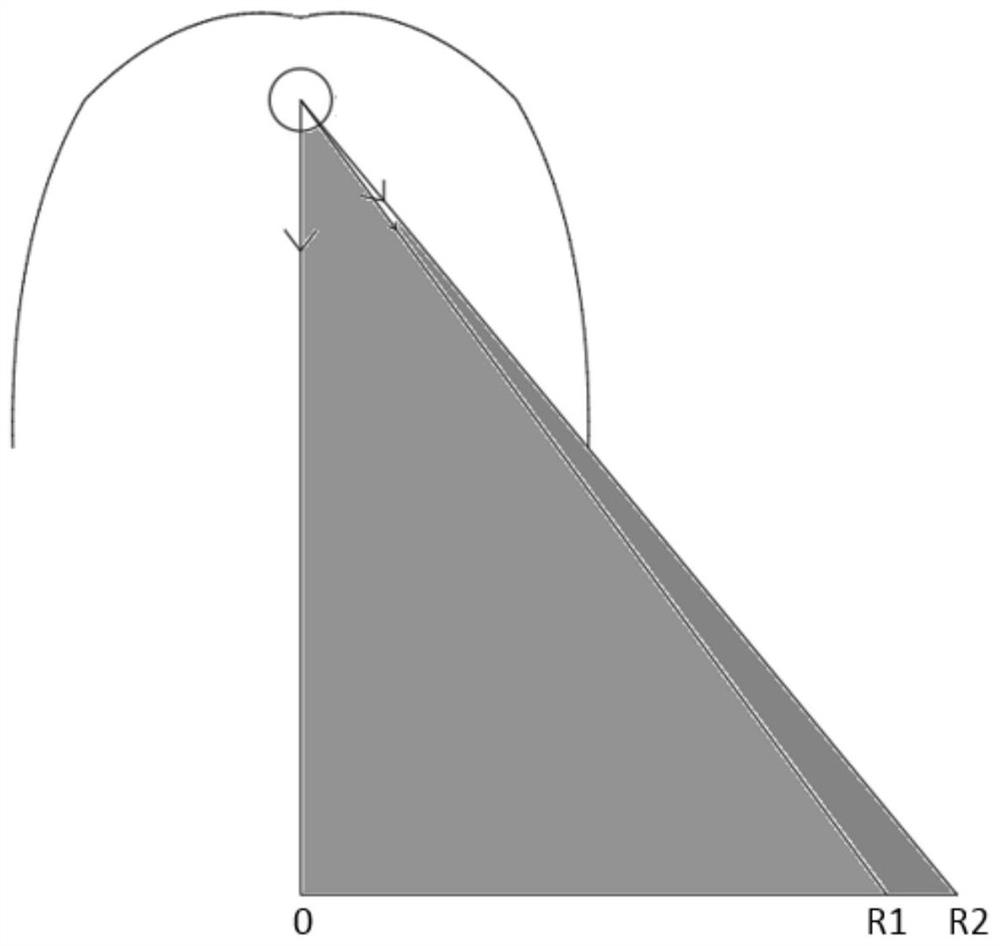

[0061] (1) Select an ultraviolet lamp with a diameter of 26.0mm, a length of 436.0mm, and a radiant energy of 4.0W as the light source, set the distance H=500mm from the illuminated surface to the exit point, and set the radius of the direct outgoing light from the exit point on the illuminated surface. The range O-R2 is 340mm, that is, a2=340mm;

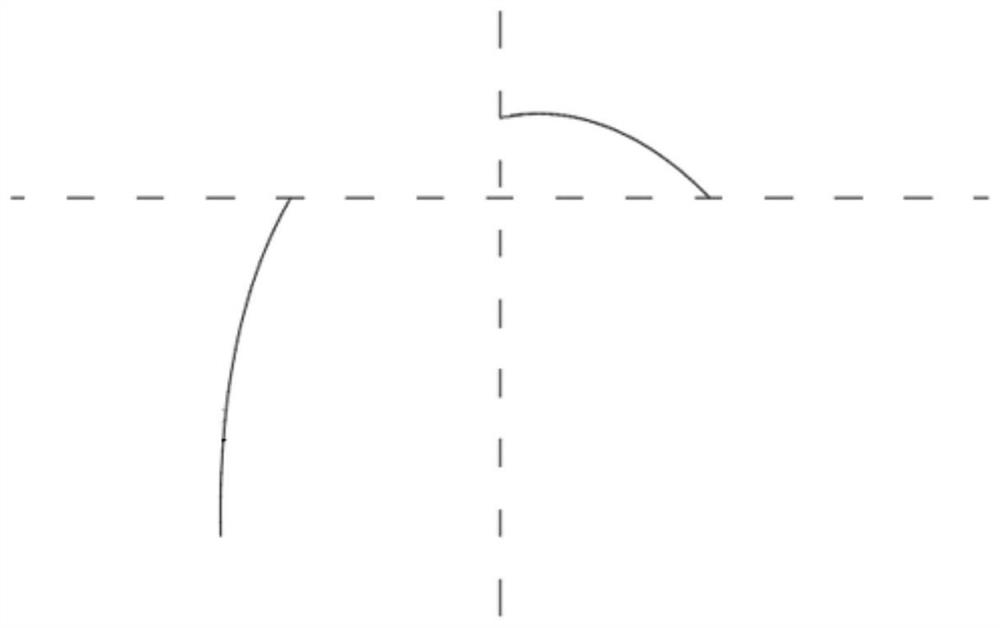

[0062] (2) Calculate the boundary point R1 according to the energy distribution equation, where the light in the range of O-R1 is the superposition of the free outgoing light and the reflected light of the upper half of the reflector, and the light in the range of R1-R2 is the free outgoing light and the lower half of the light. The superposition of the reflected light of some reflectors, and to achieve uniform illumination after superposition, the first energy distribution equation is listed as:

[0063] Solve for a1=213.7152mm, and get th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com