Light, fireproof and low-heat-conducting-property integrated disassembly-free composite heat preservation formwork and preparation process thereof

A technology of composite heat preservation and preparation technology, which is applied in the directions of heat preservation, fire prevention, and adaptation to climate change. It can solve the problems of limited scope of use, separate construction of heat preservation measures, and increased project load, so as to achieve less auxiliary equipment and occupy less space, and reduce manual labor. Strength, effect of reducing building load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

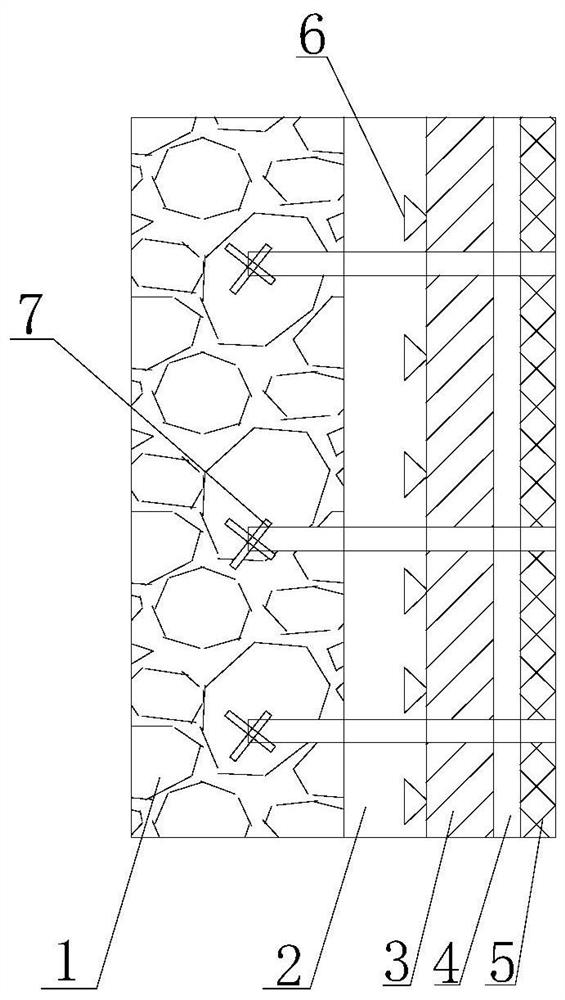

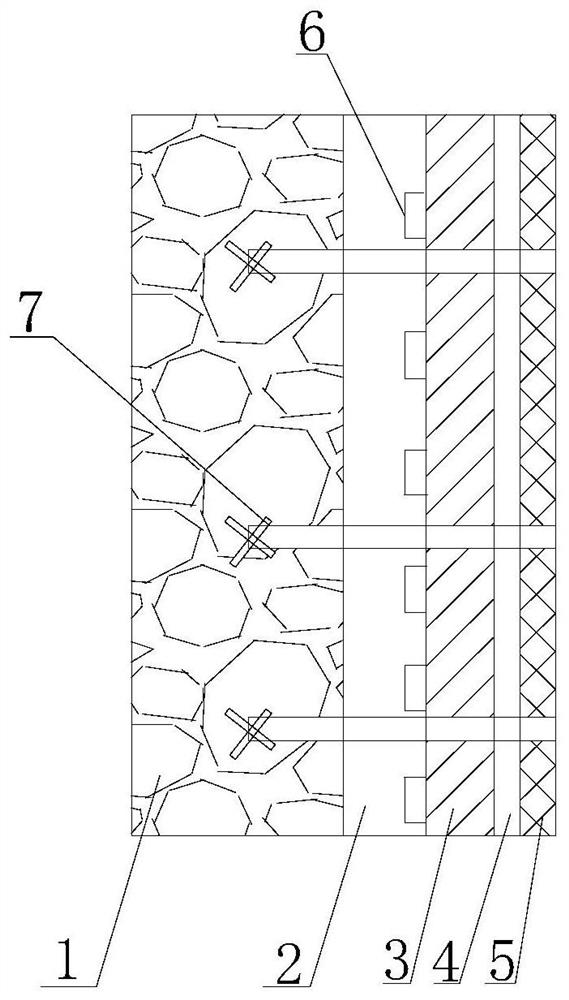

[0111] A light-weight, fireproof, low thermal conductivity integrated non-dismantling composite thermal insulation formwork, including an inner protective layer 2 connected to a concrete pouring wall 1, and the outer part of the inner protective layer 2 is provided with an insulating material layer 3 and an inorganic material protective layer in sequence 4 and the outer anti-cracking layer 5, the inner protective layer 2 is connected with the thermal insulation material layer 3, the inorganic material protective layer 4 and the outer anti-cracking layer 5 through mortise and tenon reinforcement structure, the outer anti-cracking layer 5, the inorganic The material protection layer 4, the thermal insulation material layer 3 and the inner protection layer 2 are connected and fixed with the concrete pouring wall 1 through the connection anchor bolt 6;

[0112] The materials of the thermal insulation material layer 3 and the inorganic material protective layer 4 are divided into or...

Embodiment 2

[0159] A light-weight, fireproof, low thermal conductivity integrated non-dismantling composite thermal insulation formwork, including an inner protective layer 2 connected to a concrete pouring wall 1, and the outer part of the inner protective layer 2 is provided with an insulating material layer 3 and an inorganic material protective layer in sequence 4 and the outer anti-cracking layer 5, the inner protective layer 2 is connected with the thermal insulation material layer 3, the inorganic material protective layer 4 and the outer anti-cracking layer 5 through mortise and tenon reinforcement structure, the outer anti-cracking layer 5, the inorganic The material protection layer 4, the thermal insulation material layer 3 and the inner protection layer 2 are connected and fixed with the concrete pouring wall 1 through the connection anchor bolt 6;

[0160] The materials of the thermal insulation material layer 3 and the inorganic material protective layer 4 are divided into or...

Embodiment 3

[0207] A light-weight, fireproof, low thermal conductivity integrated non-dismantling composite thermal insulation formwork, including an inner protective layer 2 connected to a concrete pouring wall 1, and the outer part of the inner protective layer 2 is provided with an insulating material layer 3 and an inorganic material protective layer in sequence 4 and the outer anti-cracking layer 5, the inner protective layer 2 is connected with the thermal insulation material layer 3, the inorganic material protective layer 4 and the outer anti-cracking layer 5 through mortise and tenon reinforcement structure, the outer anti-cracking layer 5, the inorganic The material protection layer 4, the thermal insulation material layer 3 and the inner protection layer 2 are connected and fixed with the concrete pouring wall 1 through the connection anchor bolt 6;

[0208] The materials of the thermal insulation material layer 3 and the inorganic material protective layer 4 are divided into or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com