Unbiased photoelectrochemical hydrogen production system based on InGaN nanorod photoelectrode on graphene and application thereof

A photoelectrochemical and hydrogen production system technology, applied in electrodes, nanotechnology, gaseous chemical plating, etc., can solve the problems of inability to achieve broad spectrum absorption, inability to form tandem electrodes, and opaque substrates. Biased photoelectric water splitting to produce hydrogen, improve photoelectric conversion efficiency, and inhibit the effect of recombination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

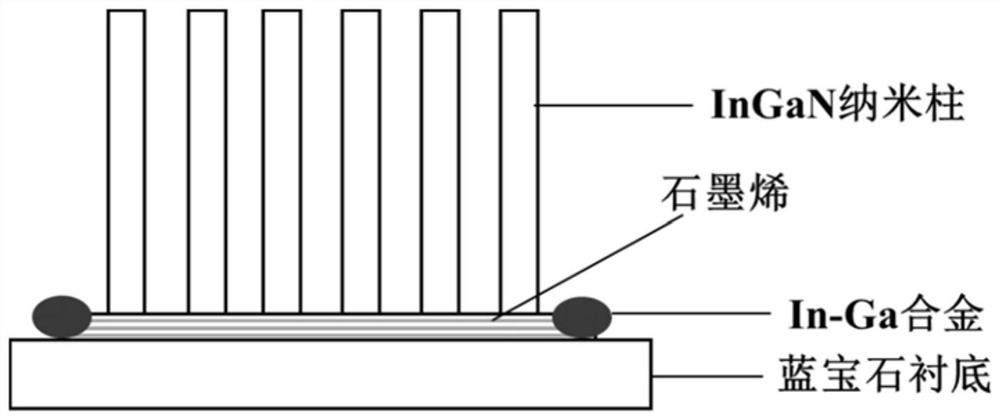

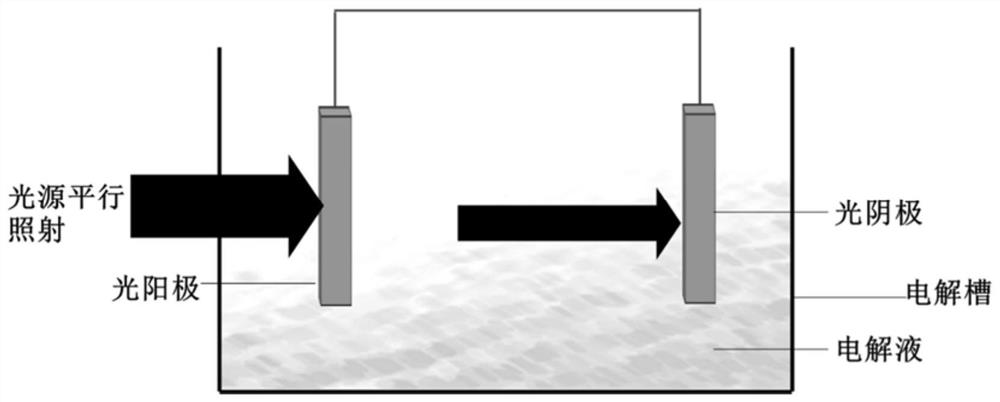

[0042]A construction of an unbiased photoelectrochemical hydrogen production system based on InGaN nanocolumn photoelectrodes on graphene, comprising the following steps:

[0043] (1) Preparation of the photoanode: use sapphire as the substrate, transfer a single-layer graphene film on the substrate by wet transfer, spin-coat PMMA solution after drying to flatten the graphene, and dry at 120 degrees Celsius for 5 minutes. Soak in acetone for 3 times, each time for 15 minutes, soak in isopropanol for 5 minutes to wash away PMMA, and obtain substrate / graphene. Then, using the molecular beam epitaxy growth process, the temperature of the substrate / graphene is controlled at 980°C, the rotation speed of the substrate / graphene is 10r / min, and the equivalent pressure of the Ga beam is 1×10 -7 Torr, In beam equivalent pressure is 2.0×10 -8 Torr, the nitrogen flow rate is 2 sccm, the plasma source power is 400W, the growth time is 3h, and the In atoms of the obtained InGaN nanocolumns...

Embodiment 2

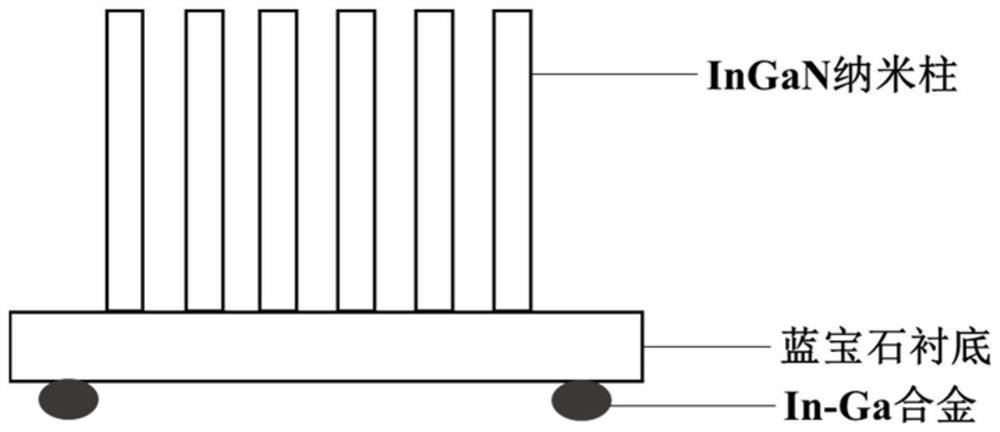

[0051] A construction of an unbiased photoelectrochemical hydrogen production system based on InGaN nanocolumn photoelectrodes on graphene, comprising the following steps:

[0052] (1) Preparation of the photoanode: Use quartz as the substrate, transfer the double-layer graphene film on the substrate by wet transfer method, spin-coat the PMMA solution after drying to flatten the graphene, and then dry it at 120 degrees Celsius for 5 minutes. Soak in acetone for 3 times, each time for 15 minutes, soak in isopropanol for 5 minutes to wash away PMMA, and obtain substrate / graphene. Then, using the molecular beam epitaxy growth process, the temperature of the substrate / graphene is controlled at 950°C, the rotation speed of the substrate / graphene is 10r / min, and the equivalent pressure of the Ga beam is 2×10 -7 Torr, In beam equivalent pressure is 3.5×10 -8 Torr, the nitrogen flow rate is 2 sccm, the plasma source power is 400W, and the growth time is 3h, and the In atoms of the ob...

Embodiment 3

[0058] A construction of an unbiased photoelectrochemical hydrogen production system based on InGaN nanocolumn photoelectrodes on graphene, comprising the following steps:

[0059] (1) Preparation of photoanode: Use sapphire as the substrate, transfer three layers of graphene film on the substrate by wet transfer method, after drying, spin-coat PMMA solution to flatten the graphene, dry at 120 degrees Celsius for 5 minutes, and then sequentially Soak in acetone for 3 times, each time for 15 minutes, soak in isopropanol for 5 minutes to wash away PMMA, and obtain substrate / graphene. Then, using the molecular beam epitaxy growth process, the temperature of the substrate / graphene is controlled at 900°C, the rotation speed of the substrate / graphene is 10r / min, and the equivalent pressure of the Ga beam is 2.5×10 - 7 Torr, In beam equivalent pressure is 5×10 -8 Torr, the flow rate of nitrogen gas is 2 sccm, the power of the plasma source is 400W, and the growth time is 3h, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com