Production method of black rice yellow wine

A production method and technology of rice yellow wine, which is applied in the field of fermentation, can solve the problems of liquid fermented wine with weak taste, high production cost, and high yield of wine, and achieve the effects of improving nutritional value and efficacy, increasing utilization rate, and improving flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

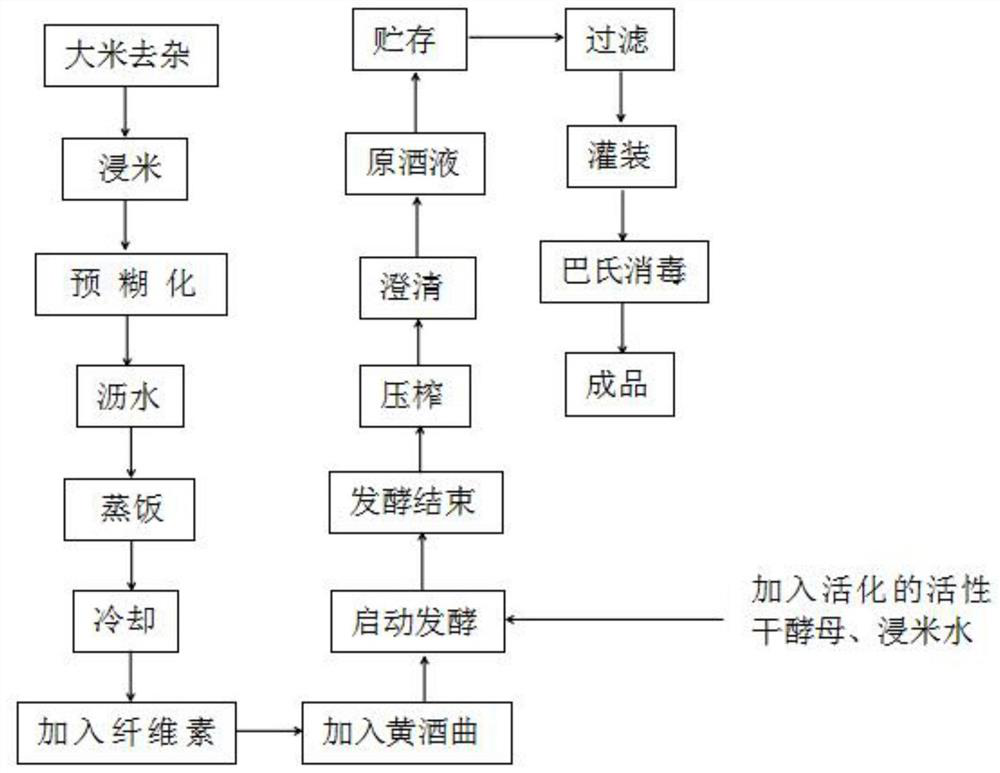

[0030] A kind of production method of black rice wine, such as figure 1 As shown, black rice is pregelatinized and enzymatically hydrolyzed, and fermented to produce rice wine. The specific production steps are as follows:

[0031] 0.5 tons of black rice, add tap water and soak at 35-40°C for 48 hours, then pass in 0.1MPa steam, stop the ventilation until the temperature of the rice soaking water is 70°C, pregelatinize for about 60 minutes, drain the water, and steam the rice under high pressure Machine steamed rice. After steaming, add cellulase when the rice is cooled to 50-60°C, the addition amount is 50U / g black rice, continue to cool to 30°C, add a small amount of water and 3.0kg of distiller's yeast to start fermentation.

[0032] Carry out to 12h in black rice fermentation, in rice, add 2 tons of rice soaking water and active dry yeast (rice wine) 4Kg through boiling and cooling, continue to ferment after mixing.

[0033] The 0-5 days of fermentation is the pre-fermen...

Embodiment 2

[0035] Add 0.4 tons of black rice, add tap water, soak for 48 hours at 35-40°C, then pass in 0.1MPa steam, stop ventilation until the temperature of rice soaking water is 60°C, soak for 60 minutes, drain the water, and steam in a high-pressure rice steamer meal. After steaming the rice, when it is cooled to 40-50°C, add 45U / g of cellulase and 6kg of koji to start the fermentation. After the fermentation is about 24 hours, add sterile water (tap water and rice soaking water) to the rice 2 tons and 4Kg of active dry yeast, mix well and continue to ferment.

[0036] The 0-5 days of fermentation is the pre-fermentation stage, which needs to be stirred every 4-5 hours, and the temperature is controlled at 26-32°C; the 6-25 days of fermentation, the temperature is controlled at 18-25°C. After the fermentation is finished, the fermented mash is filtered through a plate and frame filter press to obtain yellow rice wine liquor, the alcohol content of the liquor is 15.6% (Vol / Vol), the...

Embodiment 3

[0038] 0.4 tons of black rice, add tap water and soak at 20-25°C for about 72 hours, drain the water, and steam the rice with a high-pressure rice steamer. Add cellulase when the rice is 40-50°C, the addition amount is 50U / g black rice, add 6kg of distiller’s yeast and start fermentation, and when the fermentation is about 24h, add sterile water (tap water and rice soaking water) to the rice 2 Tons and active dry yeast 6Kg, after mixing evenly, continue to ferment.

[0039] The 0-5 days of fermentation is the pre-fermentation stage, which needs to be stirred every 4-5 hours, and the temperature is controlled at 26-32°C; the 6-25 days of fermentation, the temperature is controlled at 18-25°C. After the fermentation is finished, the fermented mash is filtered by a plate and frame filter press to obtain yellow rice wine liquor, the alcohol content of the liquor is 15.3% (Vol / Vol), the content of amino acid nitrogen in the liquor is 0.467g / L, and the chroma (A420nm) was 0.91. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com