Pressure-sensitive adhesive tamper label material and preparation method thereof

A label material and pressure-sensitive adhesive technology, applied in the field of pressure-sensitive adhesive tamper-evident label materials and their preparation, can solve the problems of general anti-counterfeiting effect, poor initial viscosity, peeling strength, and sticky physical properties of pressure-sensitive adhesives, etc. Good initial stickiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

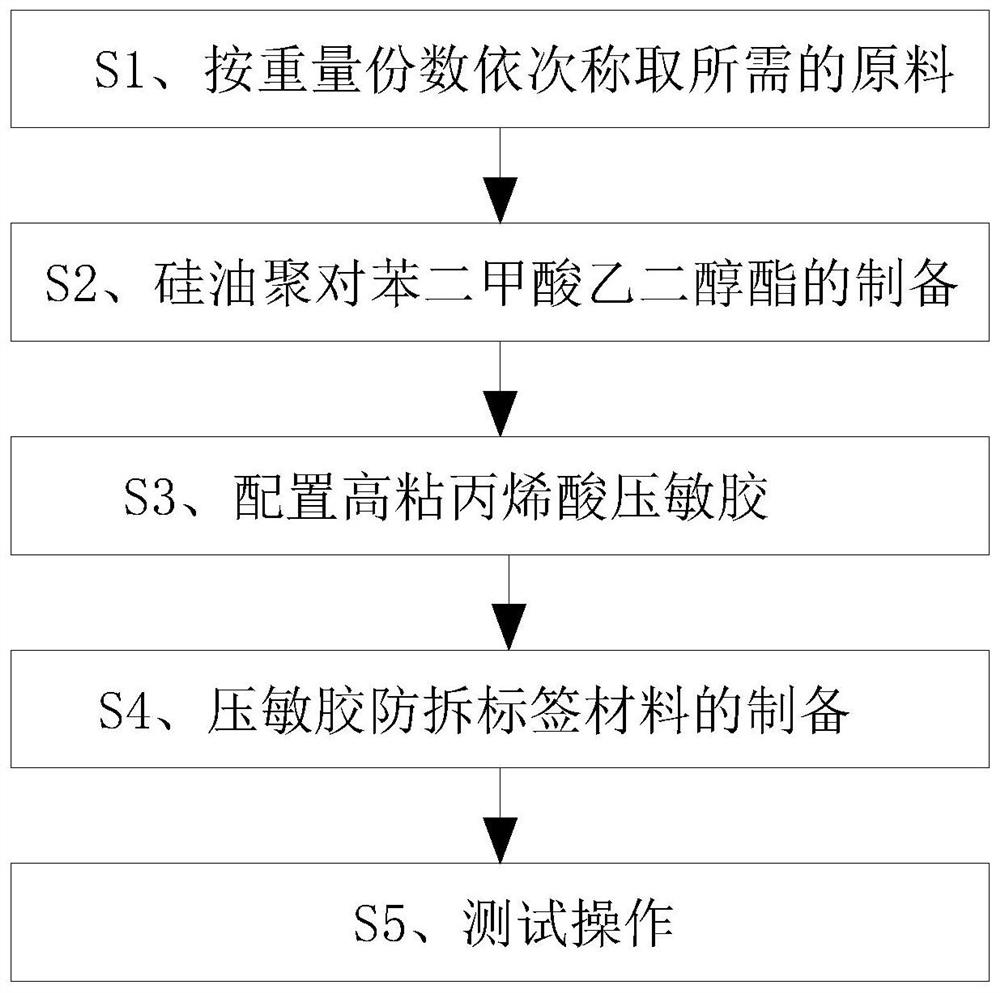

[0022] Example 1: Please refer to figure 1 , the invention discloses a pressure-sensitive adhesive tamper-proof label material, comprising the following raw materials in parts by weight: 60 parts of solvent-based methyl vinyl silicone oil ethyl acetate solution, 1 part of crosslinking agent, 3 parts of catalyst, and 10 parts of glue , 20 parts of high-viscosity acrylic pressure-sensitive adhesive and 8 parts of isocyanate curing agent.

[0023] A preparation method of a pressure-sensitive adhesive anti-tamper label material, comprising the following steps:

[0024] S1. Weigh the required raw materials in order according to the number of parts by weight: add the solvent-based methyl vinyl silicone oil ethyl acetate solution to the mixer, the solvent-based methyl vinyl silicone oil ethyl acetate solution: crosslinking agent: catalyst by 100: The ratio of 0.2:0.2 is configured, and the cross-linking agent and catalyst are sequentially added to the mixer. The cross-linking agent ...

Embodiment 2

[0029] Example 2: Please refer to figure 1 , the invention discloses a pressure-sensitive adhesive tamper-proof label material, comprising the following raw materials in parts by weight: 70 parts of solvent-based methyl vinyl silicone oil ethyl acetate solution, 4 parts of crosslinking agent, 4 parts of catalyst, and 11 parts of glue , 25 parts of high-viscosity acrylic pressure-sensitive adhesive and 9 parts of isocyanate curing agent.

[0030] A preparation method of pressure-sensitive adhesive tamper-evident label material, is characterized in that, comprises the following steps:

[0031] S1. Weigh the required raw materials in order according to the number of parts by weight: add the solvent-based methyl vinyl silicone oil ethyl acetate solution to the mixer, the solvent-based methyl vinyl silicone oil ethyl acetate solution: crosslinking agent: catalyst by 100: The ratio of 0.6:0.8 is configured, and the cross-linking agent and the catalyst are sequentially added to the ...

Embodiment 3

[0036] Example 3: Please refer to figure 1 , the invention discloses a pressure-sensitive adhesive tamper-evident label material, comprising the following raw materials in parts by weight: 80 parts of solvent-based methyl vinyl silicone oil ethyl acetate solution, 5 parts of crosslinking agent, 5 parts of catalyst, and 13 parts of glue , 30 parts of high-viscosity acrylic pressure-sensitive adhesive and 10 parts of isocyanate curing agent.

[0037] A preparation method of a pressure-sensitive adhesive anti-tamper label material, comprising the following steps:

[0038] S1. Weigh the required raw materials in order according to the number of parts by weight: add the solvent-based methyl vinyl silicone oil ethyl acetate solution to the mixer, the solvent-based methyl vinyl silicone oil ethyl acetate solution: crosslinking agent: catalyst by 100: The ratio of 0.8:1.2 is configured, and the crosslinking agent and the catalyst are sequentially added to the mixer. The crosslinking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com