Anti-disassembly electronic tag material and preparation method and use method thereof

A technology of electronic tags and anti-dismantlement, which is applied in the direction of recording carriers used in machines, instruments, computer parts, etc., can solve problems such as instability and inability to guarantee the antenna damage rate, and achieve convenient mass production, simple structure, and convenient production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manner and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

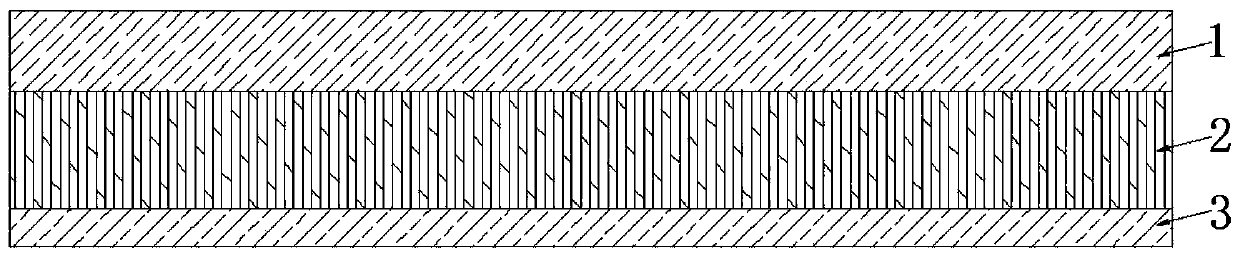

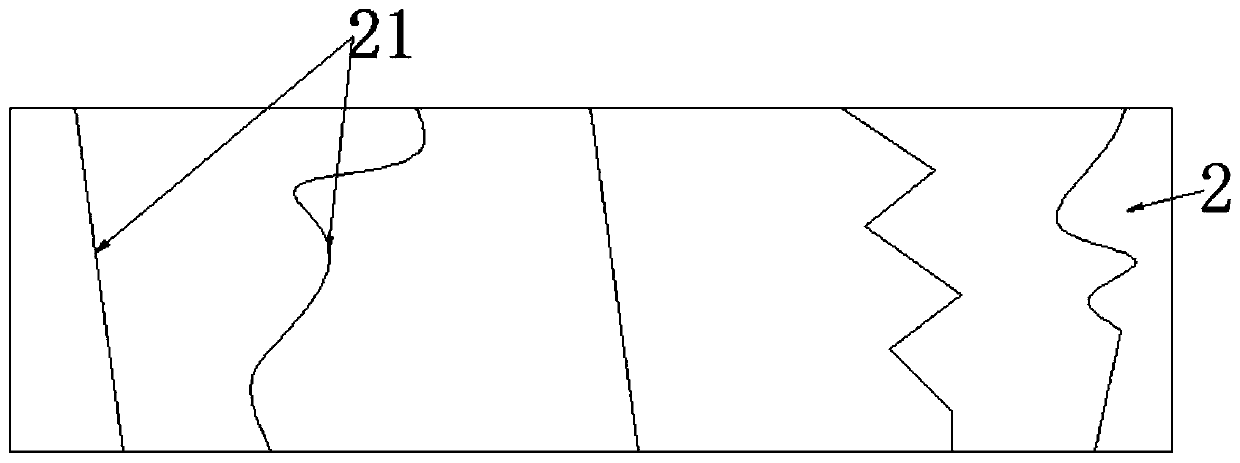

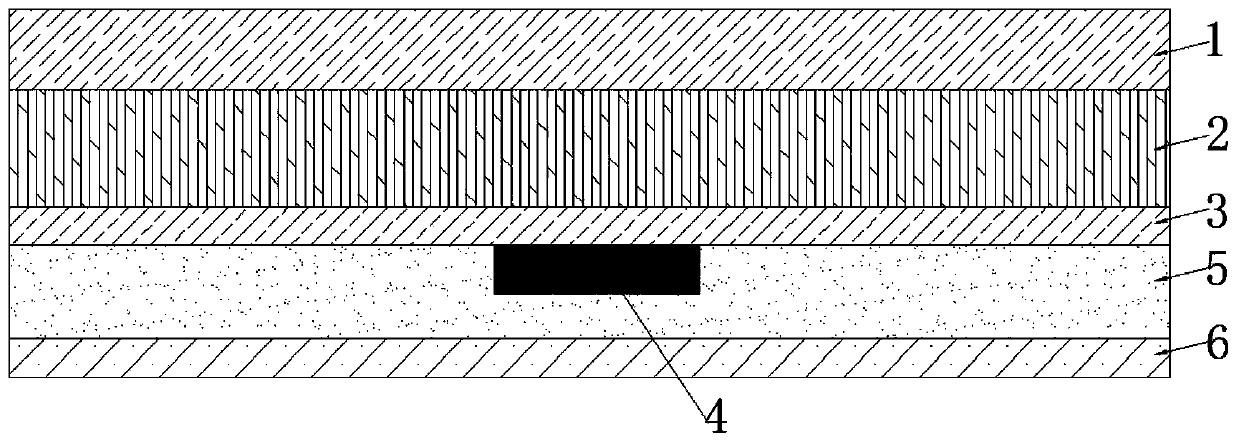

[0024] Such as figure 1 As shown, an anti-detachment type electronic label material includes a carrier substrate 1, and a detachment-proof layer 2 is covered on the carrier substrate 1, and the detachment-proof layer 2 has a release pattern 21, The release pattern 21 is a regular or irregular pattern, the width of the lines in the release pattern 21 is 1.5 mm, and the distance between two adjacent lines is 2 to 3 mm. The surface of the anti-detachment layer 2 is coated with a conductive metal layer 3 , and when the carrier substrate 1 is lifted off, the anti-detachment layer 2 and the conductive metal layer 3 are disconnected in the shape of the release pattern 21 .

[0025] After the above-mentioned electronic label material is made into an electronic label, if the label is lifted and torn off, due...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com