Deoximation type room temperature vulcanized silicone rubber and preparation method thereof

A room temperature vulcanization and silicone rubber technology, which is applied in the field of deoxime RTV silicone rubber and its preparation, can solve the problems of fracture degradation, limiting deoxime RTV silicone rubber, and heat reversion, etc., and achieves high activity and good anti-reversion. The effect of originality, high cross-linking activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

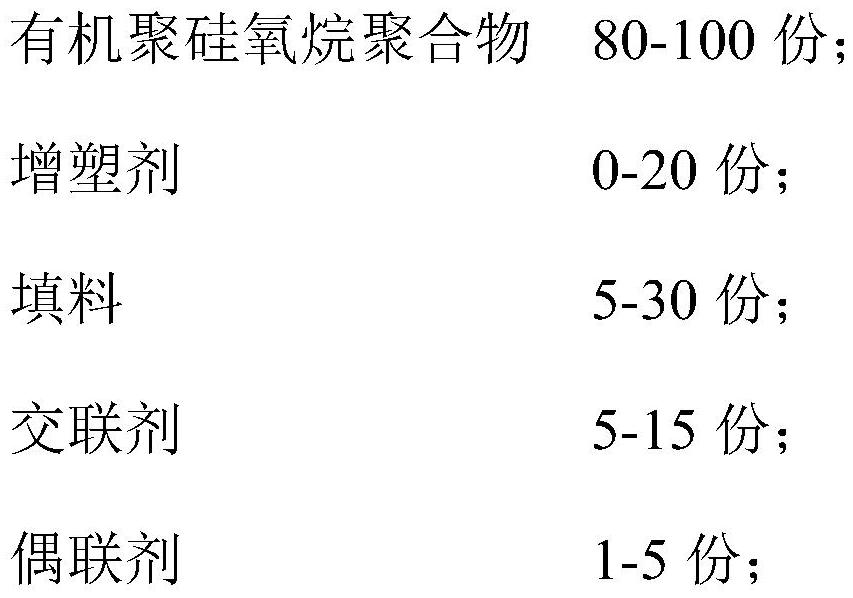

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of described linking agent comprises the following steps:

[0033] Mix silicate, butanone oxime and solvent, and heat to reflux for reaction.

[0034] The present invention uses the mixture of silicate and methyl ethyl ketone oxime after heating and refluxing reaction as cross-linking agent, finds that it has higher cross-linking activity, can omit the addition of organotin or metal salt catalyst, and achieves the same as adding. The mechanical properties of similar catalysts are basically similar, which avoids the silicone rubber in a heated and airtight environment. Because of the action of this type of catalyst, the polymer Si-O chain segment is broken and degraded, and then the silicone rubber softens, even liquefies, and returns to normal. original phenomenon. The obtained deoxime-type RTV silicone rubber has good reversion resistance, which can avoid softening of silicone rubber and decrease in mechanical properties in applications such as ...

Embodiment 1

[0064] This embodiment provides a deoxime type room temperature vulcanized silicone rubber and its preparation method, the steps are as follows:

[0065] (1) Preparation of crosslinking agent

[0066] Mix 50 parts of methyl silicate, 120 parts of methyl ethyl ketone oxime and 200 parts of toluene, heat and reflux at 160°C for 20 hours, then vacuumize to 5-10mmHg at 90°C, no distillate is considered to be a reaction stop, The mixture after the reaction is collected is the crosslinking agent.

[0067] (2) Prepare the base material

[0068] Add 100 parts of α, ω-dihydroxy polydimethylsiloxane with a viscosity of 20000mPa·s at 25°C and 80 parts of antimony trioxide into the kneader. Blending, dehydration and kneading for 180 minutes under low pressure, and discharging after cooling to obtain the base material.

[0069] (3) Preparation of deoxime type room temperature vulcanized silicone rubber

[0070] At room temperature, mix 30 parts of nano-calcium carbonate, 15 parts of th...

Embodiment 2

[0078] This embodiment provides a deoxime type room temperature vulcanized silicone rubber and its preparation method, the steps are as follows:

[0079] (1) Preparation of crosslinking agent

[0080] Mix 50 parts of methyl silicate, 120 parts of methyl ethyl ketone oxime and 200 parts of toluene, heat and reflux at 160°C for 20 hours, then vacuumize to 5-10mmHg at 90°C, no distillate is considered to be a reaction stop, The mixture after the reaction is collected is the crosslinking agent.

[0081] (2) Prepare the base material

[0082] Add 90 parts of α, ω-dihydroxy polydimethylsiloxane, 60 parts of aluminum hydroxide, and 10 parts of silicone oil at 25°C with a viscosity of 50,000 mPa·s into the kneader. Blending, dehydration and kneading for 60 minutes under the condition of ℃, and discharging after cooling to obtain the base material.

[0083] (3) Preparation of deoxime type room temperature vulcanized silicone rubber

[0084] At room temperature, mix 15 parts of whit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com