Integrated sewage treatment device and method

A technology of sewage treatment device and sewage treatment method, which is applied in biological treatment device, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems affecting the service life of MBR, long process flow, energy waste, etc. Achieve the effect of high biochemical treatment efficiency and solid-liquid separation efficiency, strengthening denitrification and denitrification, and saving operation and investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

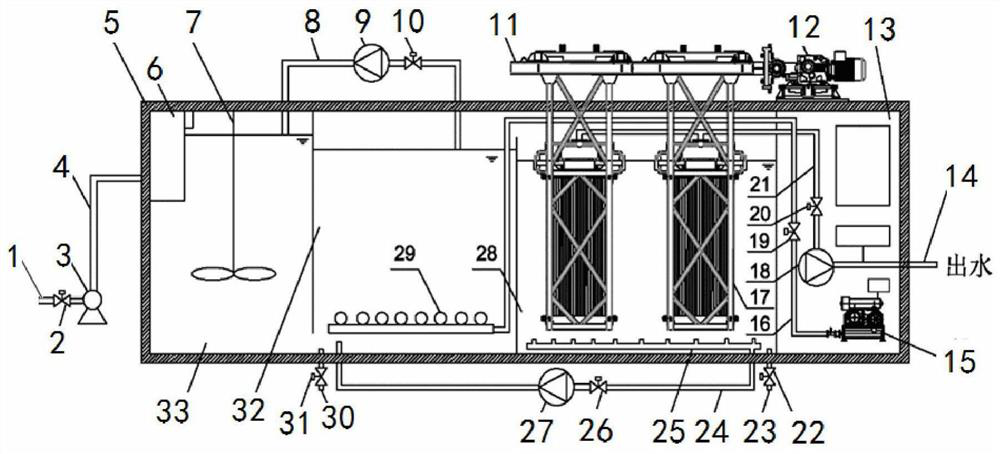

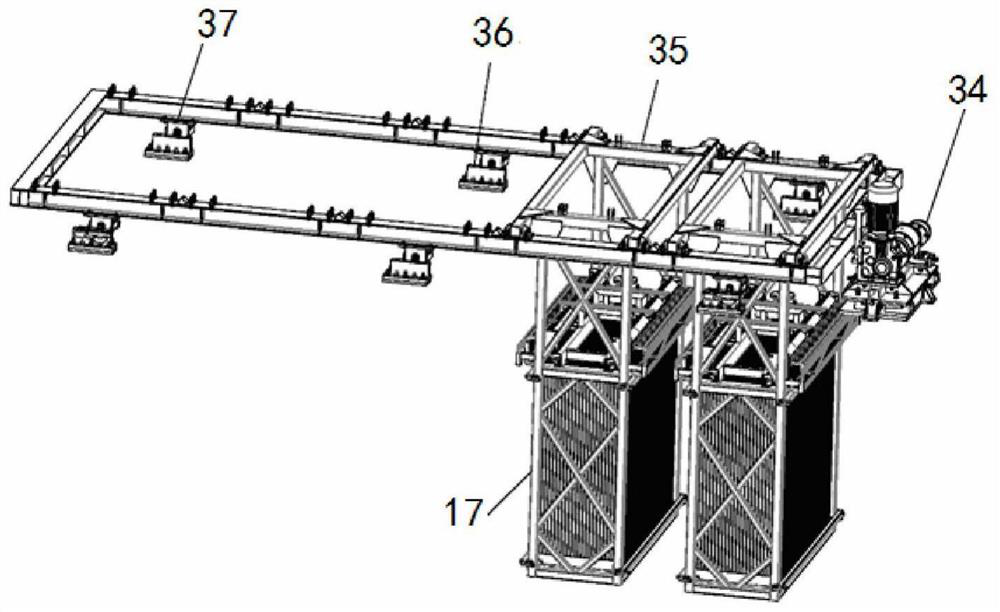

[0024] Embodiment 1: as figure 1 , figure 2 As shown in the integrated sewage treatment device, the anoxic pool 33, the aerobic pool 32, the membrane pool 28 and the equipment room 13 arranged in sequence are separated by a partition in the box body 5, wherein the anoxic pool 33 and the aerobic pool 32 The bottom is connected, the aerobic pool 32 is connected to the top of the membrane pool 28, and the equipment room 13 is connected to the membrane pool 28; the outer wall of the skeleton of the box body 5 is a Q235 steel profiled plate structure, and the anoxic pool 33 is connected to the pretreatment unit 6 and the agitator 7 and the anoxic biochemical zone, the first water inlet pipe 1 is connected to the first valve 2, the other end of the first valve 2 is connected to the water inlet lifting pump 3, the other end of the water inlet lifting pump 3 is connected to the second water inlet pipe 4, and the second water inlet The other end of the water pipe 4 communicates with ...

Embodiment 2

[0033] Embodiment 2: as figure 1 , figure 2 As shown, the integrated sewage treatment device and method, the low-energy MBR process, and the in-situ membrane cleaning method ensure the efficient, low-consumption and stable operation of the MBR integrated sewage treatment equipment.

[0034] (1) A movable integrated sewage treatment equipment is adopted, that is, an anoxic pool, an aerobic pool, a membrane pool and an equipment room arranged in sequence are separated by a partition in a box structure, wherein the anoxic pool and the good The bottom of the oxygen tank is connected, the aerobic tank is connected to the top of the membrane tank, and the equipment room is close to the membrane tank; the box adopts an integrated modular design, the production quality and cycle are controllable, the cost is low, the structure is compact, the floor space is small, and it is easy to transport and maintenance, capable of fully automatic operation and remote intelligent monitoring, sui...

Embodiment 3

[0044] Embodiment 3: as figure 1 , figure 2 As shown, the integrated sewage treatment device and method, the low-energy MBR process, and the in-situ membrane cleaning method ensure the efficient, low-consumption and stable operation of the MBR integrated sewage treatment equipment.

[0045] ① A mobile integrated sewage treatment equipment: in a box structure, the anoxic pool, aerobic pool, membrane pool and equipment room are separated in sequence by partitions, wherein the anoxic pool is connected to the bottom of the aerobic pool , The aerobic tank is connected to the top of the membrane tank, and the equipment room is close to the membrane tank; the box adopts an integrated modular design, the production quality and cycle are controllable, the cost is low, the structure is compact, the floor space is small, and it is convenient for transportation and maintenance. Realize fully automatic operation and remote intelligent monitoring, suitable for the treatment of distributed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com