Adhesive film cutting device for wafer

A technology for cutting equipment and wafers, which is applied to the cleaning method of tools, cleaning methods and utensils, metal processing, etc., and can solve the problems of inconsistent wafer surface size, inability to use the wafer surface normally, and the edge of the adhesive film Wrinkle and other problems, to achieve the effect of reducing sticking to the outer wall of the rotating ring and reducing the adsorption force as the rotating ring rotates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

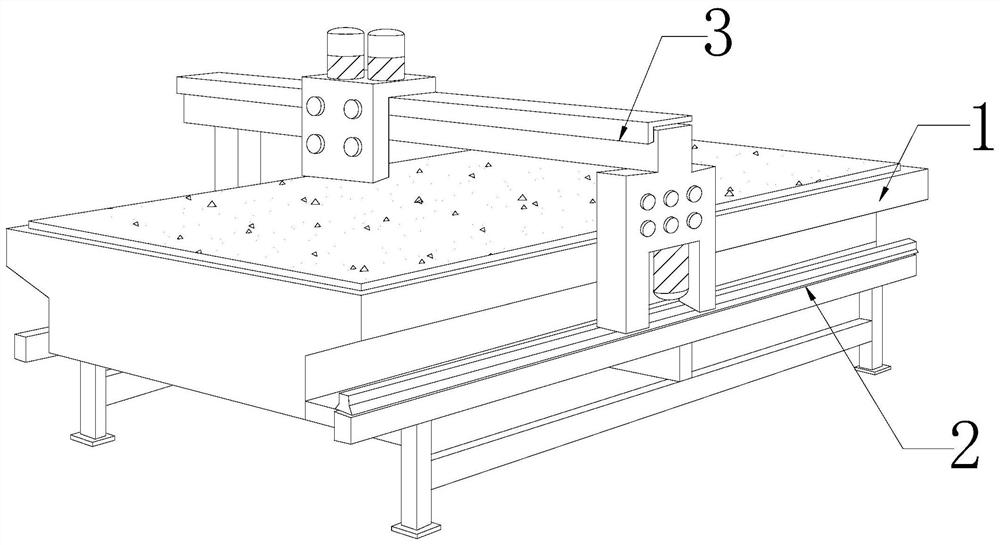

[0027] as attached figure 1 To attach Figure 5 Shown:

[0028] The present invention provides a film cutting device for wafers. Its structure includes a body 1, a slider 2, and a gantry 3. The slider 2 is horizontally installed in the middle of both sides of the body 1. The gantry 3 is located at Above the body 1, and in cooperation with the slide block 2.

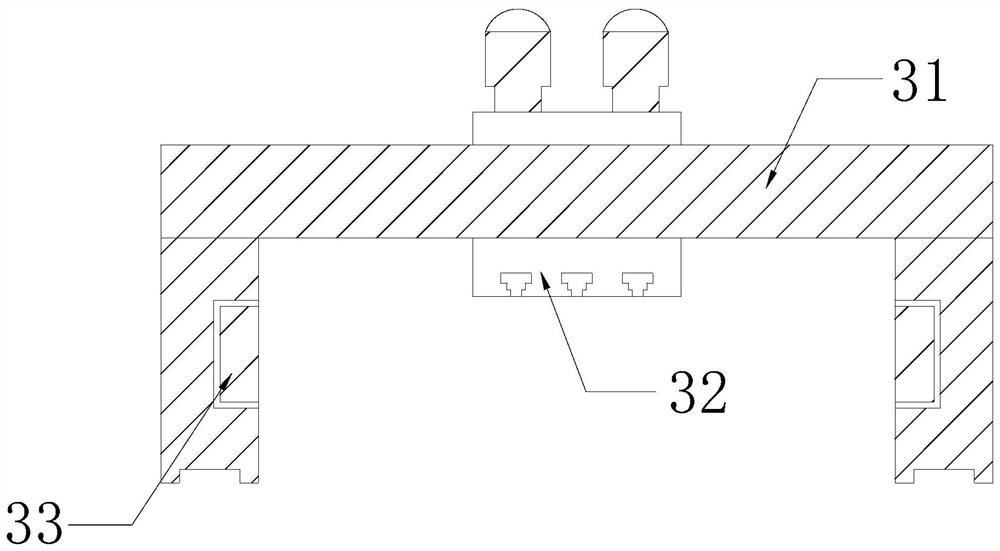

[0029] Described gantry frame 3 is provided with support frame 31, cutter 32, limit mechanism 33, and described support frame 31 is positioned at the outside of gantry frame 3, and described cutter 32 is vertically installed on support frame 31 top center position, and described limiter The mechanism 33 is nested inside the middle part of the support frame 31 .

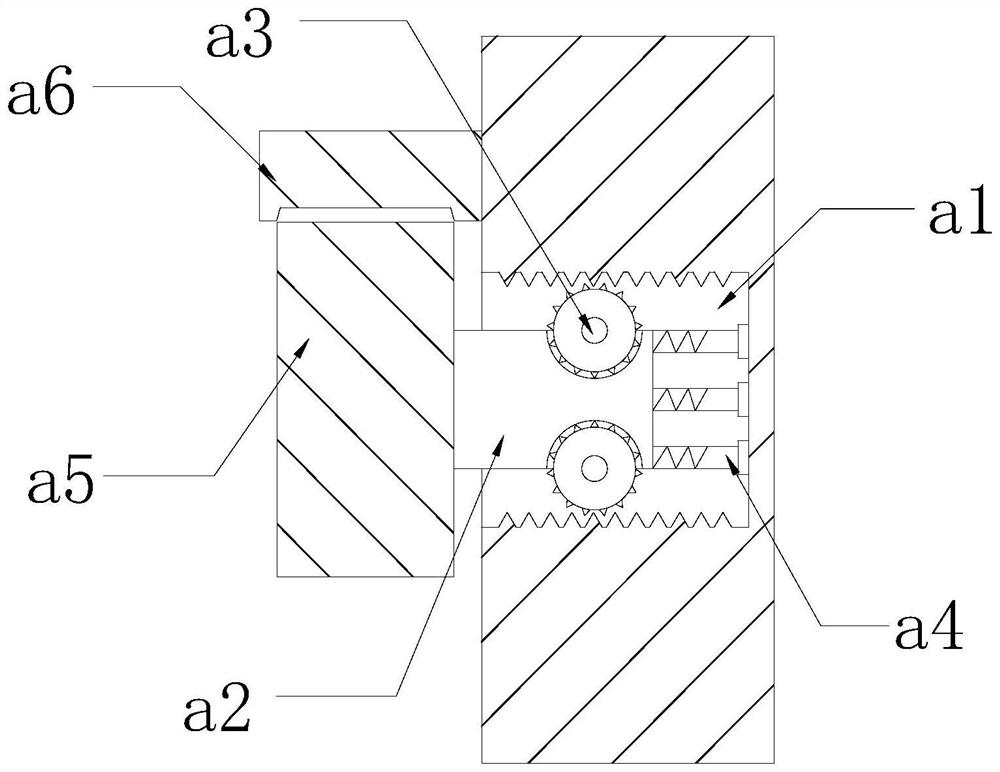

[0030] Wherein, the limit mechanism 33 is provided with a matching groove a1, a support rod a2, a gear a3, a telescopic rod a4, a rotating ring a5, and a matching block a6. The right end of the support rod a2 is sleeved inside the matching groove a1, the gear...

Embodiment 2

[0036] as attached Image 6 To attach Figure 8 Shown:

[0037]Wherein, the matching block a6 is provided with an expansion rod e1, an active groove e2, an air cavity e3, a push plate e4, and a limit rod e5, and the expansion rod e1 is installed on the right side of the matching block a6, and the active groove e2 is arranged on In the middle of the bottom surface of the matching block a6, the air cavity e3 is set inside the matching block a6 and above the movable groove e2, the push plate e4 is set inside the bottom of the air cavity e3, and the limit rod e5 is installed on the push plate e4 Between the tops of both ends and the inner wall of the air cavity e3, the top of the push plate e4 has an uneven surface, which can increase the force-bearing area of the top of the push plate e4 and speed up the airflow inside the air cavity e3 when the push plate e4 moves up. Promote diffusion, the expansion rod e1 is provided with two, and is at the same horizontal angle, which is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com