Processing method for printed-circuit connector of PCB of high-speed photoelectric coupling module

A photoelectric coupling and printed plug technology, which is applied in printed circuit manufacturing, electrical components, printed circuits, etc., to improve quality, reduce costs, meet the effects of mass production and safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

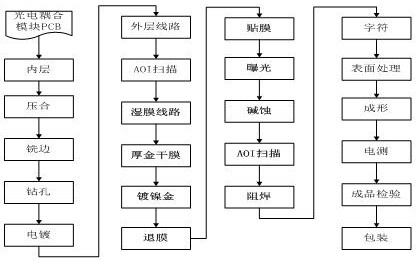

[0040] A processing method for printing a plug PCB with a high-speed photoelectric coupling module, which is characterized in that it includes the following steps: photoelectric coupling module PCB→inner layer→pressing→edge milling→drilling→electroplating→outer layer circuit→AOI scanning→wet film Circuit → thick gold dry film → nickel-plated gold → film removal → lamination → exposure → alkaline etching → AOI scanning → solder mask → characters → surface treatment → forming → electrical measurement → finished product inspection.

[0041] Furthermore, in the outer circuit, each gold finger makes an inner pull lead with a width of 5mil. The junction area of the gold finger lead line set needs to be crossed to the edge of the board in the X and Y directions. The circuit is made according to this file.

[0042] Further, in the AOI scan after the outer circuit, AOI calls the outer engineering data scan with lead wires to confirm the defects, and the CCD magnification of the re-ins...

Embodiment 2

[0056] A processing method for printing a plug PCB with a high-speed photoelectric coupling module, which is characterized in that it includes the following steps: photoelectric coupling module PCB→inner layer→pressing→edge milling→drilling→electroplating→outer layer circuit→AOI scanning→wet film Circuit → thick gold dry film → nickel-plated gold → film removal → lamination → exposure → alkaline etching → AOI scanning → solder mask → characters → surface treatment → forming → electrical measurement → finished product inspection.

[0057] Furthermore, in the outer circuit, each gold finger makes an inner pull lead with a width of 5mil. The junction area of the gold finger lead line set needs to be crossed to the edge of the board in the X and Y directions. The circuit is made according to this file.

[0058] Further, in the AOI scan after the outer circuit, AOI calls the outer engineering data scan with leads to confirm the defect, and the CCD magnification of the re-inspectio...

Embodiment 3

[0072] A processing method for printing a plug PCB with a high-speed photoelectric coupling module, which is characterized in that it includes the following steps: photoelectric coupling module PCB→inner layer→pressing→edge milling→drilling→electroplating→outer layer circuit→AOI scanning→wet film Circuit → thick gold dry film → nickel-plated gold → film removal → lamination → exposure → alkaline etching → AOI scanning → solder mask → characters → surface treatment → forming → electrical measurement → finished product inspection.

[0073] Furthermore, in the outer circuit, each gold finger makes an inner pull lead with a width of 5mil. The junction area of the gold finger lead line set needs to be crossed to the edge of the board in the X and Y directions. The circuit is made according to this file.

[0074] Furthermore, in the AOI scan after the outer circuit, AOI calls the outer engineering data scan with leads to confirm the defect, and the CCD magnification of the re-inspe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com