Modified acrylate polymer composition

A polymethyl methacrylate and polymer technology, applied in the field of polymer materials, can solve the problems of difficult to meet comprehensive mechanical properties and poor compatibility, and achieve high impact resistance, good application prospects, and high surface gloss The effect of degree and weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

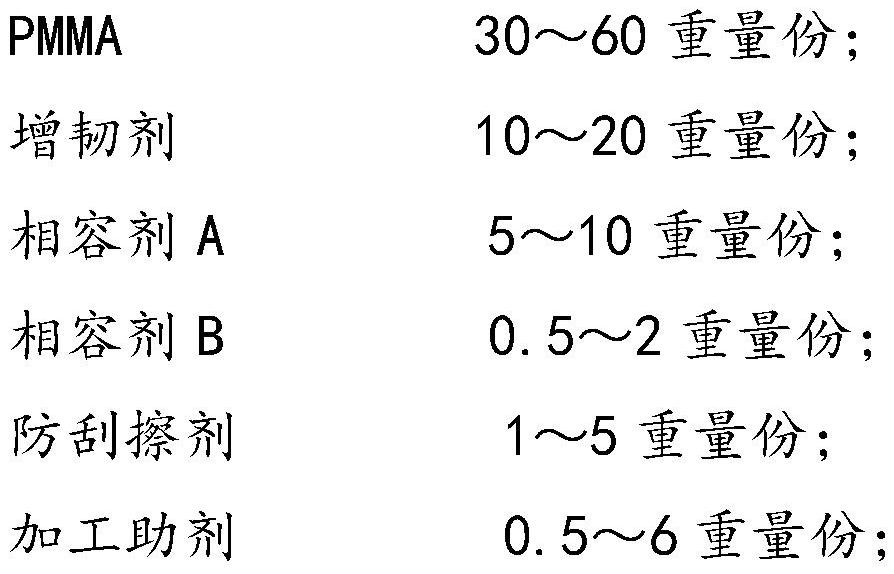

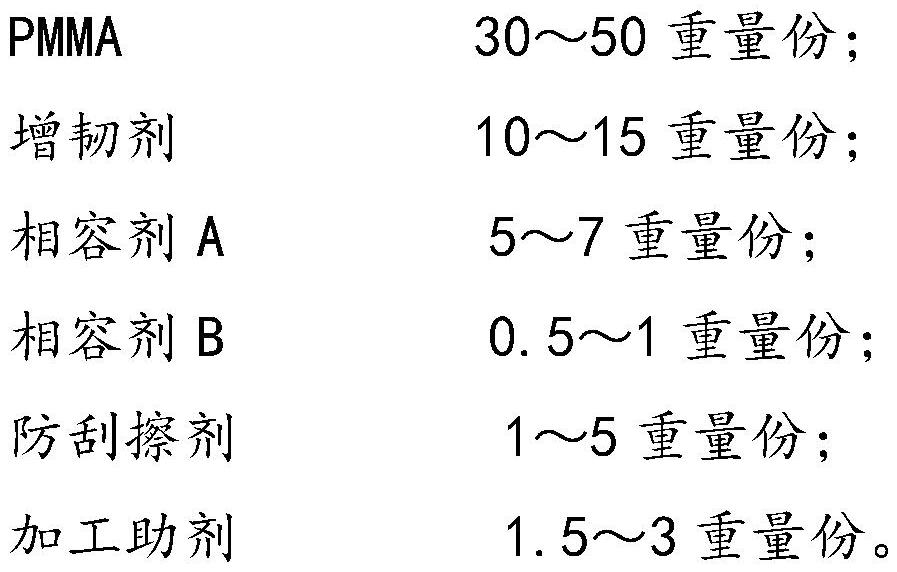

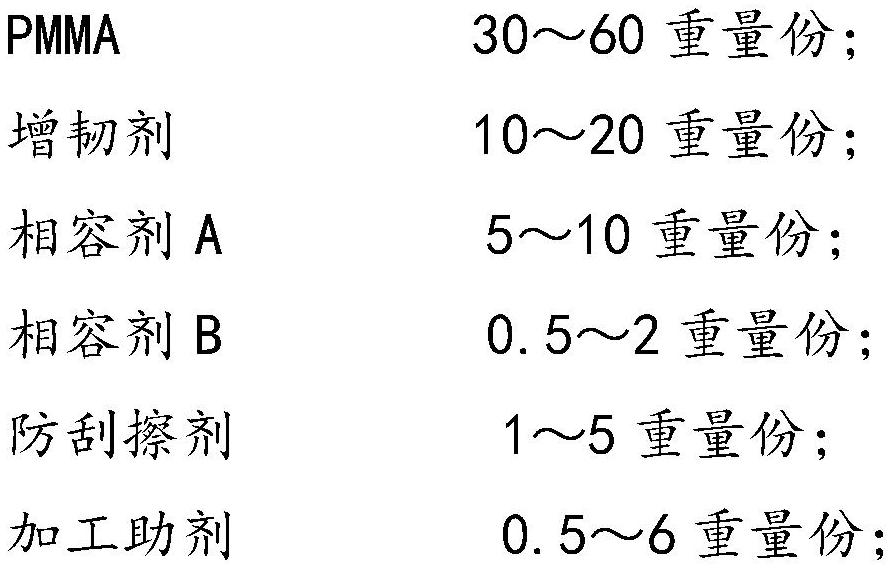

Method used

Image

Examples

Embodiment 1

[0043] The composition of the modified PMMA / ASA polymer composition is shown in Table 1 below.

[0044] According to the different weight and number ratios in the following table 1, the following raw material components were weighed respectively: PMMA resin, ASA rubber powder, MBS resin, compatibilizer B, magnesium stearate and processing aid; and carried out in a high-speed mixer Premix for 5 minutes to obtain a premix. Wherein, the weight-average molecular weight of the PMMA resin is 50000g / mol; the ASA rubber powder is obtained by agglomeration and drying of an emulsion with a latex particle size (D50) of 300nm, and the bulk density of the rubber powder is 0.35g / cm 3 , the rubber powder particle size (D50) is 100 μm, the rubber phase content is 60wt%, the mass ratio of the polybutylacrylate core layer and the styrene-acrylonitrile shell layer is 1:0.6, and the rubber crosslinking degree is 75%; MBS resin is obtained by emulsion agglomeration drying of 300nm by latex partic...

Embodiment 2

[0047] The composition of the modified PMMA / ASA polymer composition is shown in Table 1 below.

[0048] According to the different weight and number ratios in the following table 1, the following raw material components were weighed respectively: PMMA resin, ASA rubber powder, MBS resin, compatibilizer B, magnesium stearate and processing aid; and carried out in a high-speed mixer Premix for 5 minutes to obtain a premix. Wherein, the weight-average molecular weight of the PMMA resin is 150,000 g / mol; the ASA powder is obtained by agglomeration and drying of an emulsion with a latex particle size (D50) of 100 nm, and the bulk density of the powder is 0.30 g / cm 3 , the rubber powder particle size (D50) is 50 μm, the rubber phase content is 40wt%, the mass ratio of the polybutylacrylate core layer and the styrene-acrylonitrile shell layer is 1:0.3, and the rubber crosslinking degree is 80%; MBS resin is obtained by emulsion agglomeration drying of 100nm by latex particle diamete...

Embodiment 3

[0051] According to the different weight and number ratios in the following table 1, the following raw material components were weighed respectively: PMMA resin, ASA rubber powder, MBS resin, compatibilizer B, magnesium stearate and processing aid; and carried out in a high-speed mixer Premix for 5 minutes to obtain a premix. Wherein, the weight-average molecular weight of the PMMA resin is 2,000,000 g / mol; the ASA rubber powder is obtained by agglomeration and drying of an emulsion with a latex particle size (D50) of 500 nm, and the bulk density of the rubber powder is 0.40 g / cm 3 , the rubber powder particle size (D50) is 200 μm, the rubber phase content is 80wt%, the mass ratio of the polybutylacrylate core layer and the styrene-acrylonitrile shell layer is 1:1, and the rubber crosslinking degree is 80%; MBS resin is obtained by emulsion agglomeration and drying of 500nm by latex particle diameter (D50). The molar ratio of the ester is 6:4, and the rubber phase content in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com