Dust removal spraying device for green building construction

A green building and spraying device technology, which is applied in the direction of using liquid separating agent, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of wasting water resources, pedestrian impact, and large sprinkler volume, so as to prevent waste and save energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

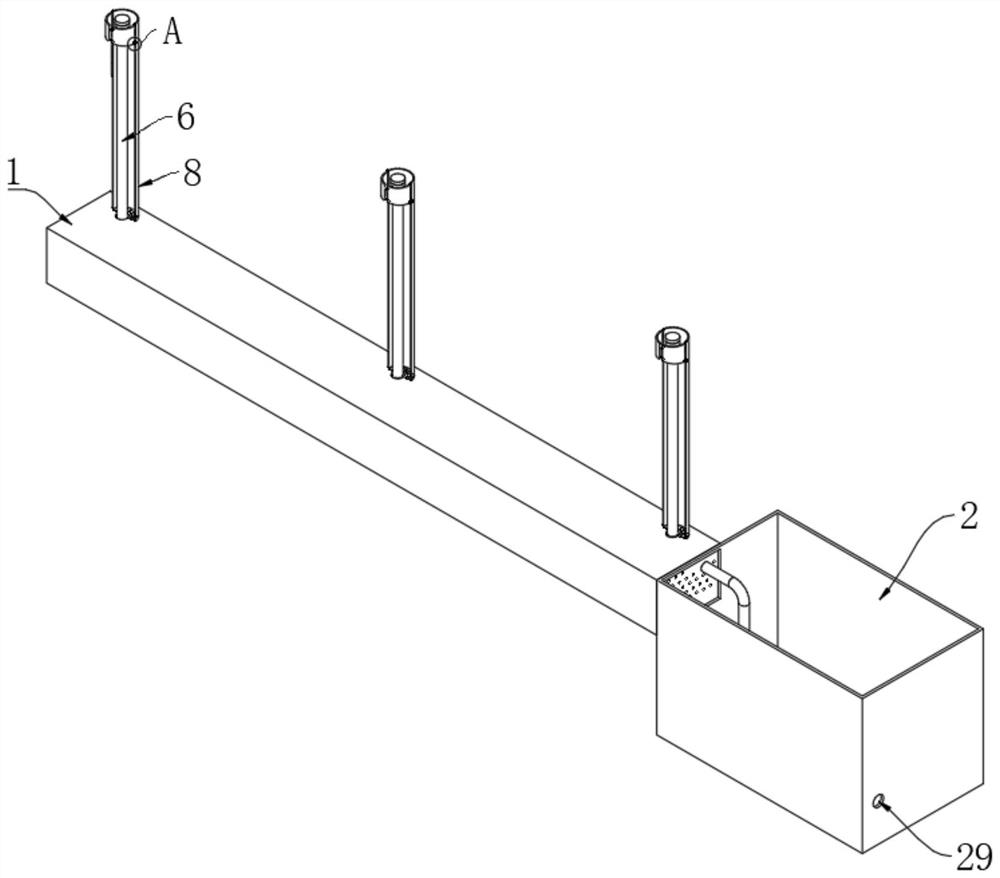

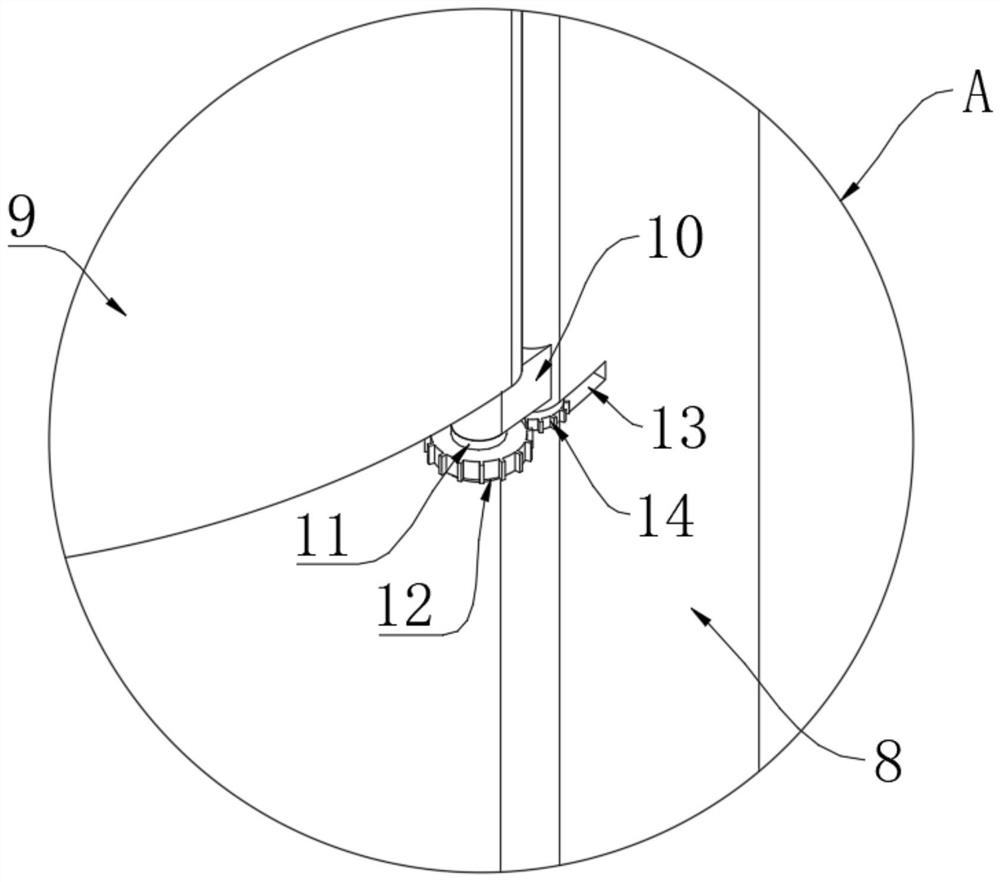

[0030] like Figure 1-7 The shown dust removal and spraying device for green building construction includes a collection box 1, the collection box 1 is a hollow structure, and a reservoir 2 is provided on one side of the collection box 1, and the reservoir 2 communicates with the interior of the collection box 1, and A filter screen 33 is fixed between the collection box 1 and the reservoir 2 .

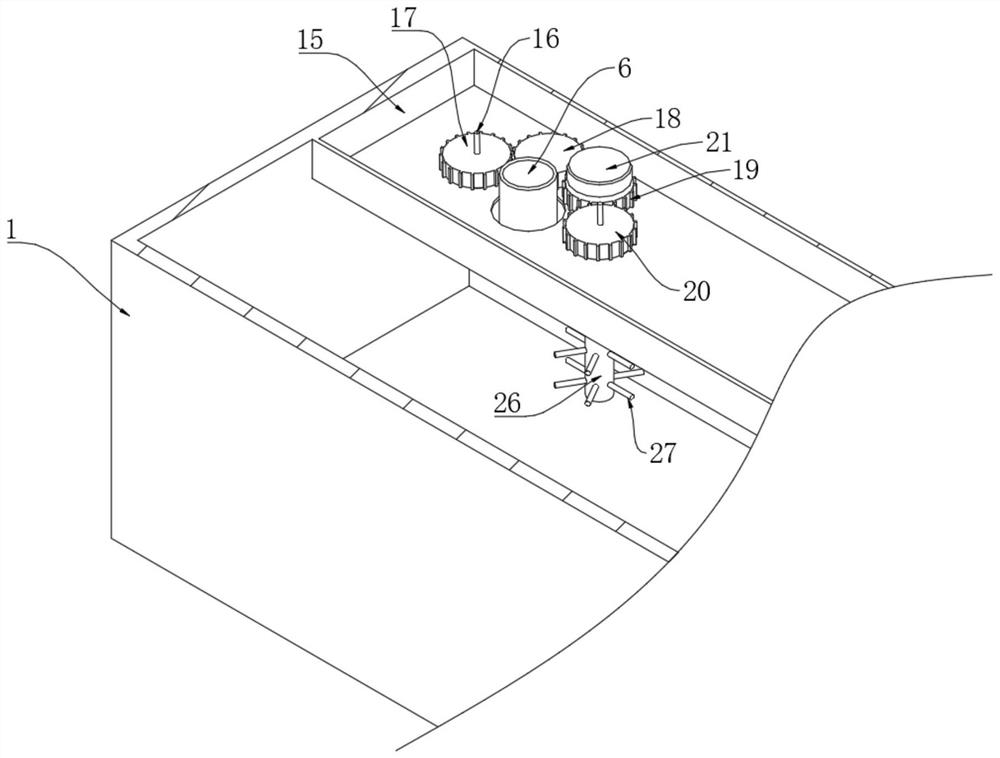

[0031] A drive box 15 is fixed on the top of the collection box 1, and a drive mechanism is arranged inside the drive box 15. A horizontal tube 5 is placed inside the collection box 1. One end of the horizontal tube 5 is fixed on the inner wall of the collection box 1, and the other end of the horizontal tube 5 run...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com