Full-automatic plastic film capacitor metal spraying machine

A technology of plastic film and capacitor, which is applied in the manufacture of thin film/thick film capacitors, capacitors, capacitors, etc. It can solve the problems of waste of gold powder, time-consuming repeated gold spraying, and low quality, so as to improve production efficiency, uniform powder receiving, and facilitate collection of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025]Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

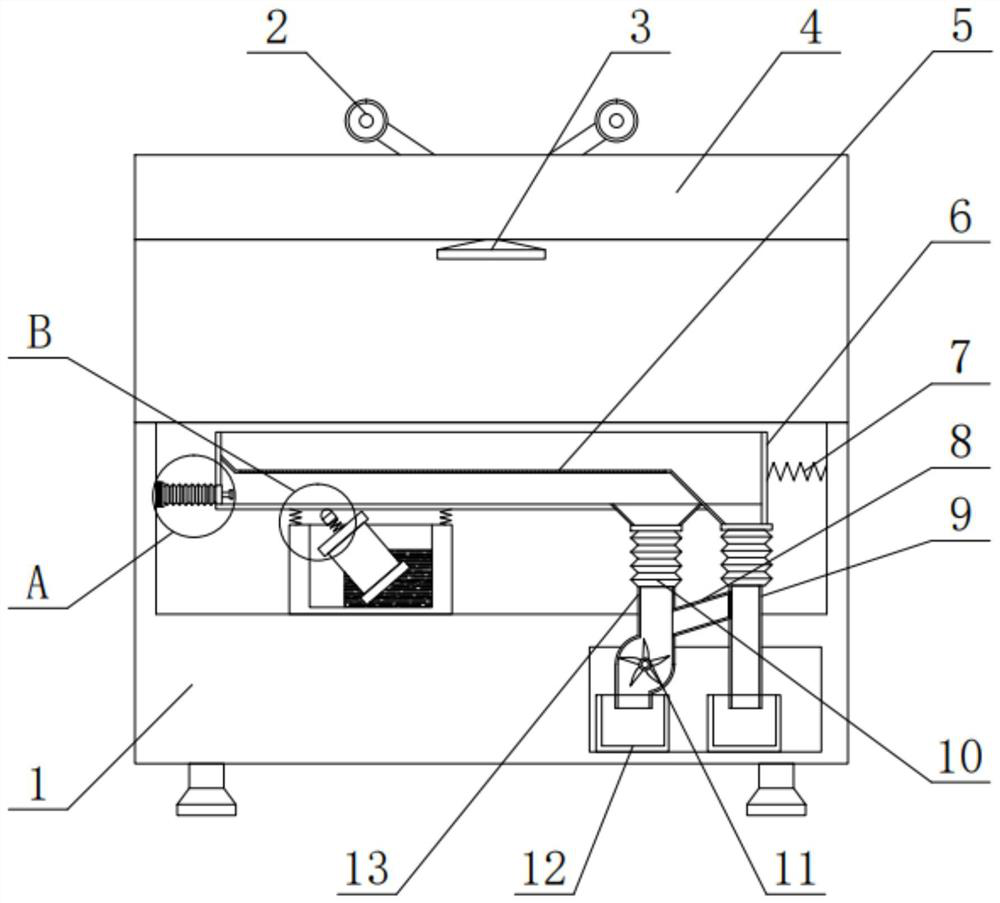

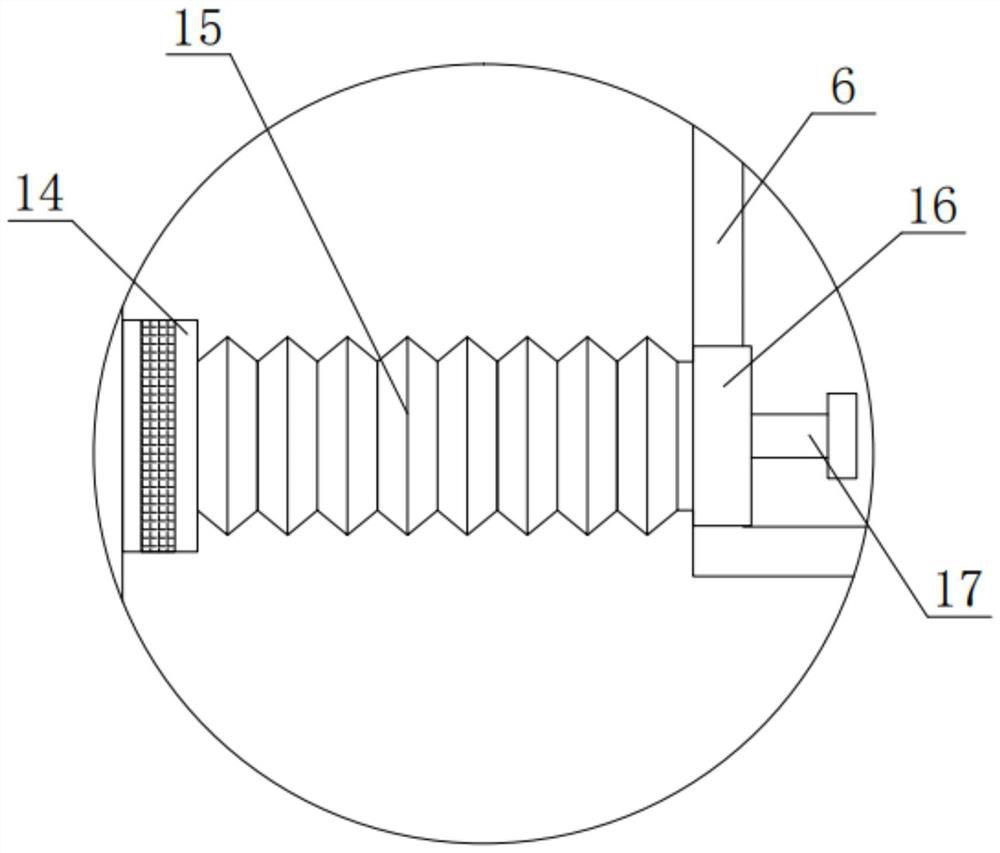

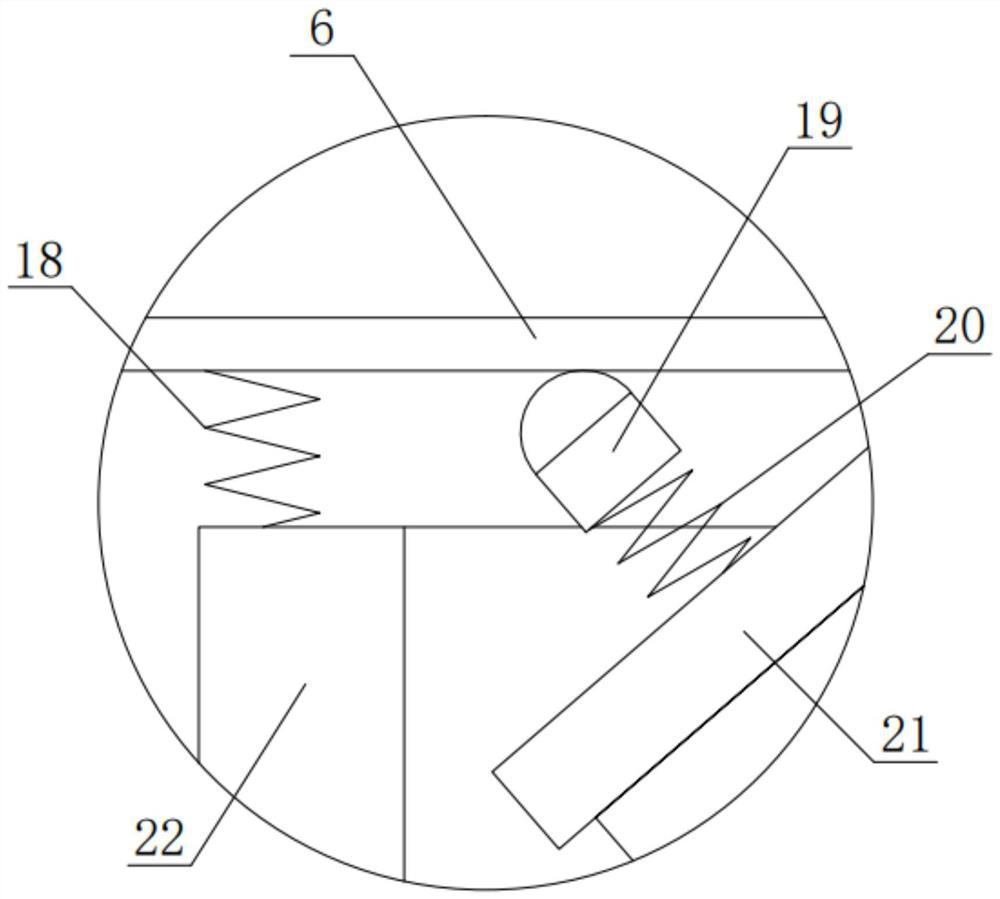

[0026]SeeFigure 1-3The present invention provides a technical solution: a fully automatic plastic thin film capacitor golness, including the automatic spray gold box 1 and the top frame 4, and two guide wheel 2 is disposed in the upper end of the top frame 4, Two wire sources are continuously transferred to the arc processing position by two wire sources 2, and then the two wire touches, and the two wires are in contact with the two wires. In an instant, an arc is generated, and a metal powder is generated at the time of discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com