Iron-silicon-aluminum magnetic powder core microwave insulation coating method and insulation coating magnetic powder core

An insulating coating and sendust technology, applied in the direction of magnetic materials, magnetic objects, inorganic materials, etc., can solve the problems of low efficiency and poor effect of magnetic powder core coating, and achieve stable molding strength and powder core sensitivity Sexuality, easy technology promotion, convenient and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

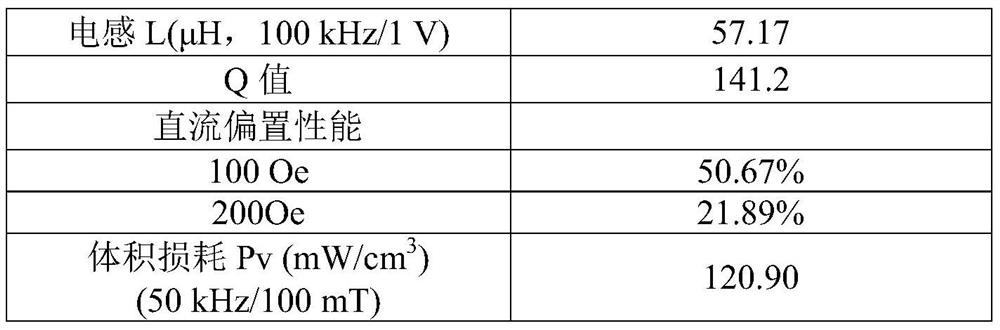

[0039] A microwave insulation coating method for sendust magnetic powder core, comprising the following steps:

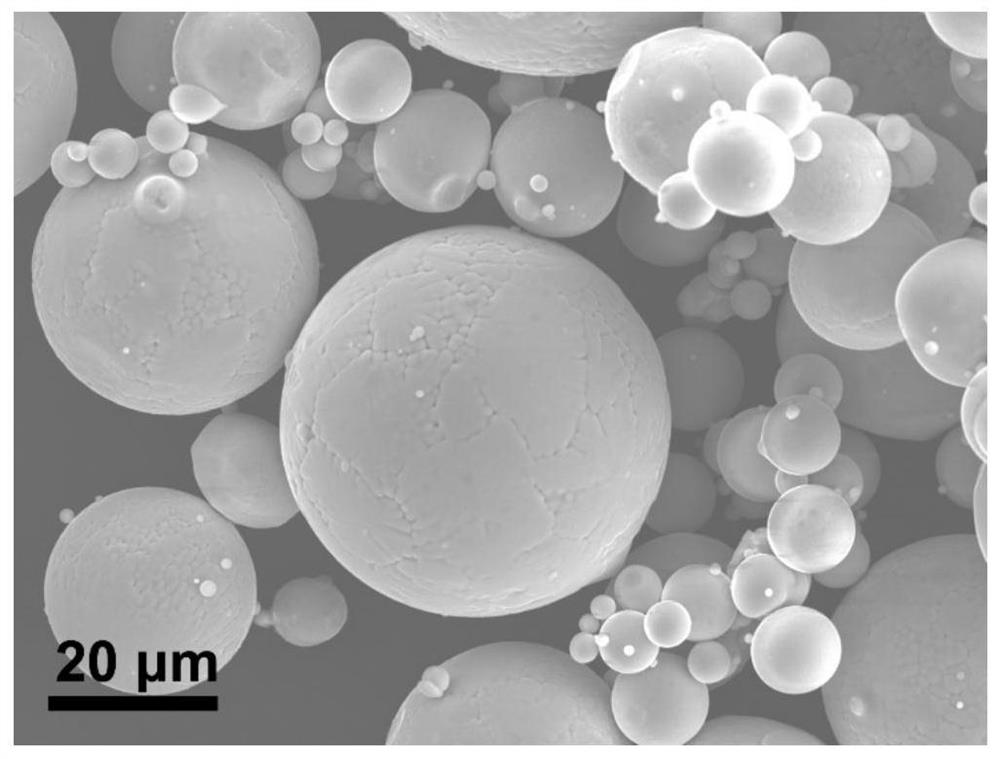

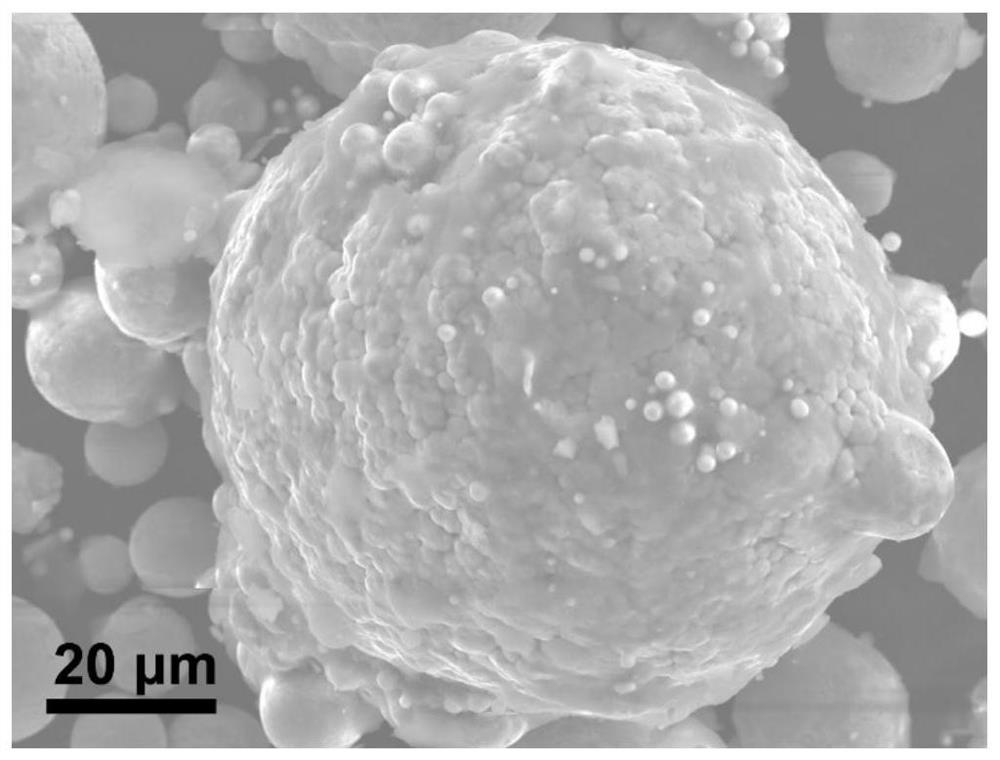

[0040] S1: Preparation of mixed slurry: use sendust magnetic powder with a particle size of less than 200 meshes prepared by gas atomization as raw material, the raw material is 1000 g, and based on the mass of the sendust magnetic powder, add polyvinyl alcohol with a concentration of 2.0% Solution 150g, SiO 2 5g powder, stirred at room temperature for 3 minutes, and stirred evenly to form a mixed slurry;

[0041] S2: Microwave heating: Put the mixed slurry into a microwave heater with a microwave frequency of 2000MHz, and microwave for 10 minutes to obtain dry magnetic powder; sieve the dry magnetic powder with a 100-mesh sieve to remove large particles;

[0042] S3: Prepare the magnetic powder to be formed: add 1 g of binder silicone resin powder and 1 g of release agent zinc stearate to the dried magnetic powder after sieving, and mix evenly to obtain the magnet...

Embodiment 2

[0049] A microwave insulation coating method for sendust magnetic powder core, comprising the following steps:

[0050] S1: Preparation of mixed slurry: use sendust magnetic powder with a particle size of less than 200 meshes prepared by the gas atomization method as raw material, the raw material is 1000 g, and based on the mass of the sendust magnetic powder, add polyvinyl alcohol with a concentration of 3.0% Solution 120g, SiO 2 Powder 10g, stirred at room temperature for 5 minutes, and stirred evenly to form a mixed slurry;

[0051] S2: Microwave heating: Put the mixed slurry into a microwave heater with a microwave frequency of 2200 MHz, and heat it with microwave for 8 minutes to obtain dry magnetic powder; sieve the dry magnetic powder with a 100-mesh sieve to remove large particles;

[0052] S3: Prepare the magnetic powder to be formed: add 2 g of binder silicone resin powder and 2 g of release agent zinc stearate to the dried magnetic powder after sieving, and mix ev...

Embodiment 3

[0059] A microwave insulation coating method for sendust magnetic powder core, comprising the following steps:

[0060] S1: Preparation of mixed slurry: use sendust magnetic powder with a particle size of less than 200 meshes prepared by gas atomization as raw material, the raw material is 1000 g, and based on the mass of the sendust magnetic powder, add polyvinyl alcohol with a concentration of 5.0% Solution 90g, SiO 2 15g powder, stirred at room temperature for 7 minutes, and stirred evenly to form a mixed slurry;

[0061] S2: Microwave heating: put the mixed slurry into a microwave heater with a microwave frequency of 2300MHz, and microwave for 6 minutes to obtain dry magnetic powder; sieve the dry magnetic powder with a 100-mesh sieve to remove large particles;

[0062] S3: Prepare the magnetic powder to be formed: add 2.5g of binder silicone resin powder and 3g of release agent zinc stearate to the dried magnetic powder after sieving, and mix evenly to obtain the magneti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com