Electrical valve

An electric valve and valve body technology, applied in valve details, valve devices, engine components, etc., can solve the problems of manual switching, inconvenience in production and maintenance, and safety, and achieve the benefits of production and maintenance, standardization, and realization. generalized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

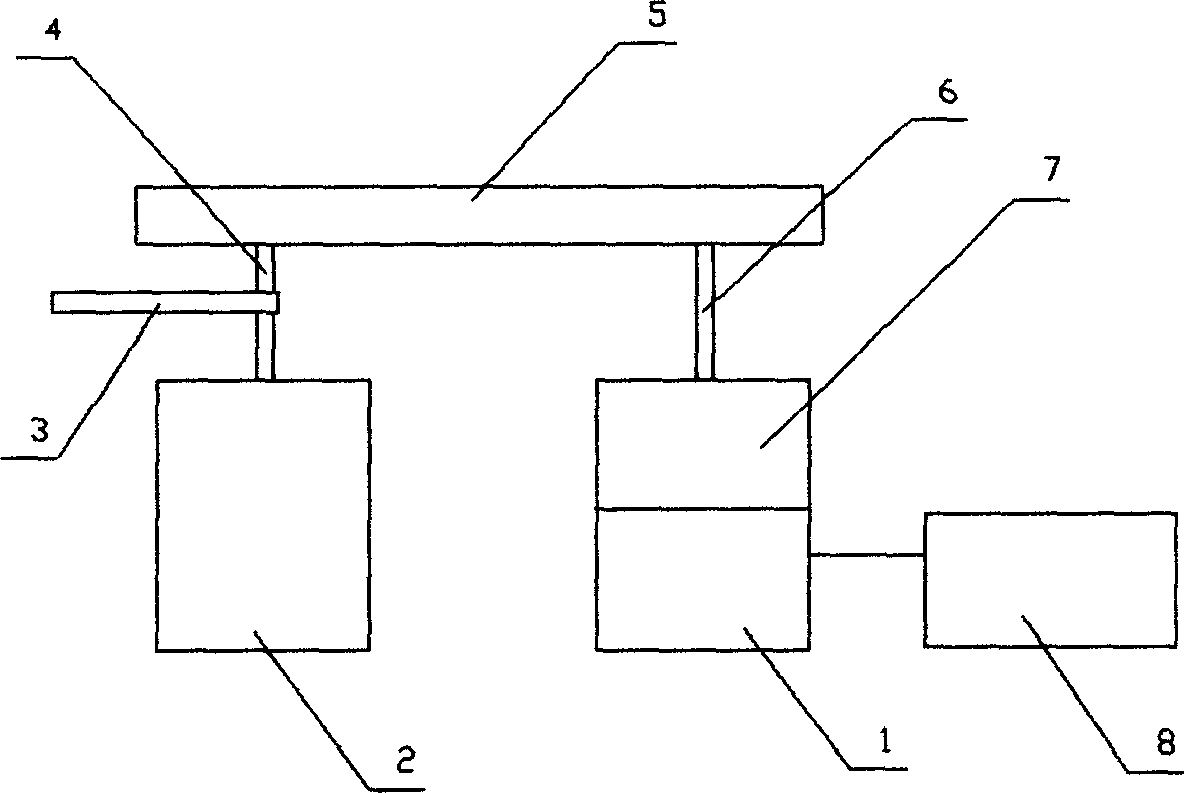

[0007] Referring to the accompanying drawings, the present invention relates to an electric valve, which includes a valve body 2 and a motor 1. The movable part in the valve body is provided with a valve stem 4 for controlling the opening and closing of the valve, and the valve stem extends from the top of the valve body to the outside of the valve body. , and is driven and connected to the motor through a transmission mechanism outside the valve body, and the motor is provided with a control device 8 for controlling its operation.

[0008] The present invention can be provided with a limiting device that limits the rotation range of the valve stem, so as to avoid damage to the internal structure of the valve body caused by excessive rotation of the valve stem.

[0009] Described position-limiting device can adopt any prior art, can comprise the position-limiting structure that is arranged on the rotating part (so-called position-limiting structure refers to a part or all on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com