Direct-current bushing voltage-sharing device based on low-conductivity temperature coefficient epoxy composite material

A temperature coefficient and composite material technology, applied in the direction of circuits, electrical components, lead-in/through-type insulators, etc., to achieve the effects of reducing electric field strength, reasonable design, and preventing abnormal discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

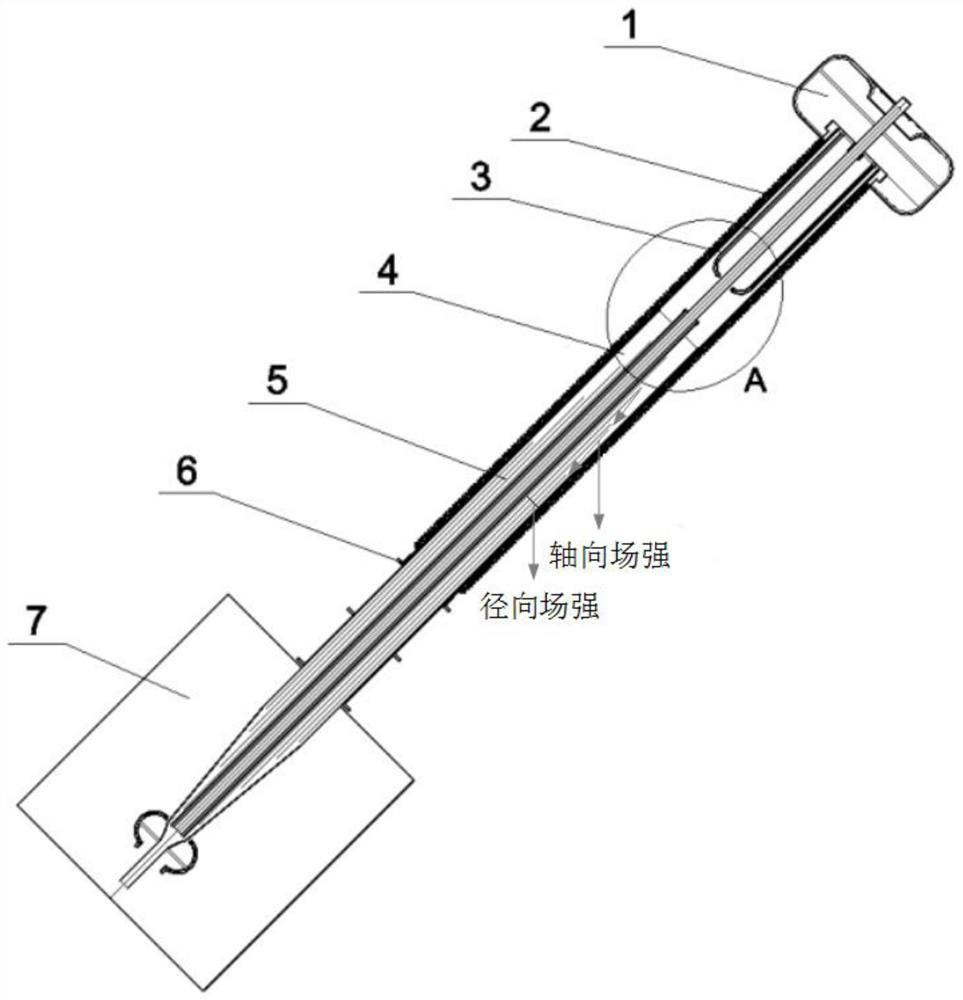

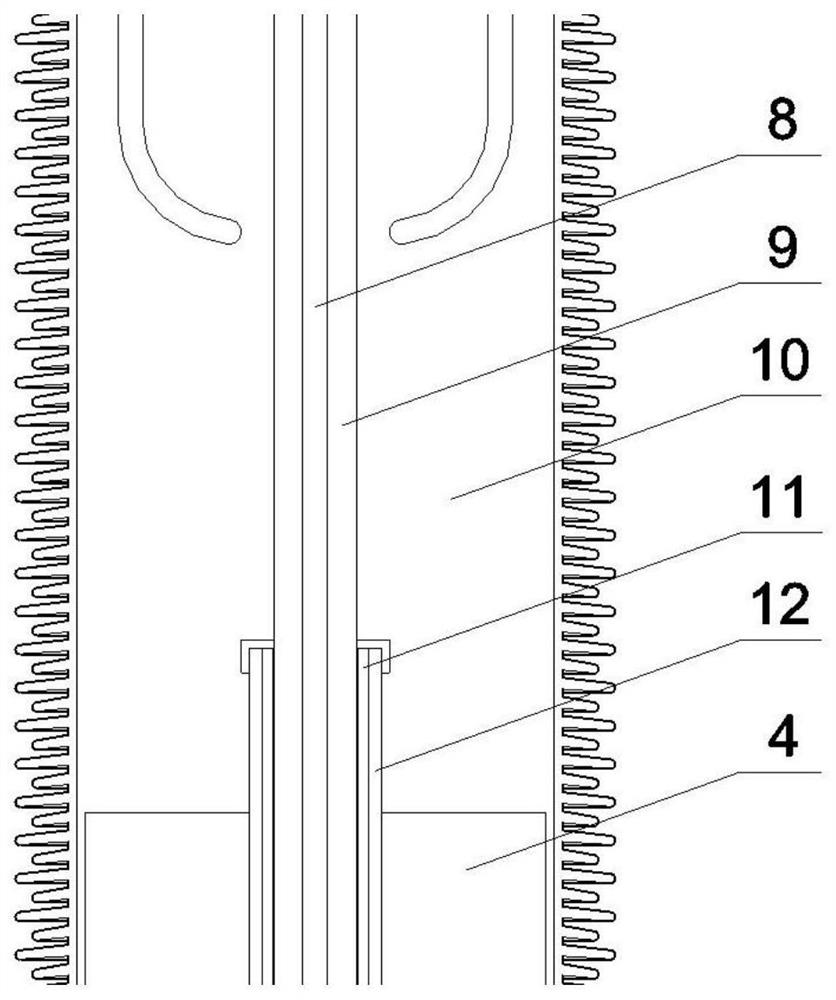

[0024] A DC bushing voltage equalization device based on epoxy composite material with low conductivity temperature coefficient, such as figure 1 and figure 2 As shown, it includes bushing 2 , bushing capacitor core 4 , metal flange 6 , current-carrying conductor 9 , and outer conductor 12 . The outside of the casing is an outer shed, and a pressure equalizing ring 1 is installed at the upper and lower ends of the casing, and an inner pressure equalizing ring 3 is installed inside the upper end of the casing, which can be used to prevent abnormal discharge. The current-carrying conductor is installed in the center of the bushing and its two ends are fixed together with the equalizing ring. The current-carrying conductor is a hollow structure with air 8 in the center, and epoxy impregnated paper is used to wrap around the current-carrying conductor. The out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com