Novel high-sealing-performance connecting gear

A technology of connecting gears and high sealing, applied in belts/chains/gears, components with teeth, portable lifting devices, etc. The problem of poor matching accuracy can achieve the effect of good shock absorption, good stability, and ensure the tightness of the connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

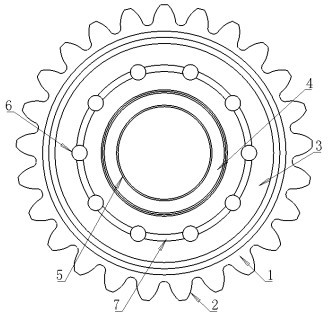

[0016] Such as Figure 1 to Figure 4 As shown, a new type of high-tightness connecting gear, its main structure adopts a symmetrical structure design up and down, and the assembly connection groove structure is set at its upper and lower ends respectively, so that the tightness of the assembly connection is better, so that Ensure that the connection stability during use is more reliable, and the locking assembly connection is performed by setting the locking connection assembly hole structure inside the assembly connection groove, so that the fastening connection effect during assembly is better, and the connection during use The safety is higher. It also sets a shock-absorbing sealing connection groove structure at the position of the locking connection assembly hole, so that it can be assembled and connected with a shock-absorbing washer structure during assembly, so that the stability of the assembly connection of the gear structure is better. , and can make the gear struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com