Semi-rigid assembly type comprehensive pipe gallery and construction method thereof

A comprehensive pipe gallery and prefabricated technology, applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve the problems of closed deviation pipe gallery, groundwater leakage, short construction period, etc., to achieve short construction period and easy and precise construction , to avoid the effect of groundwater infiltration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Specific embodiments of the present invention are described in detail below, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

[0037] Unless expressly stated otherwise, throughout the specification and claims, the term "comprise" or variations thereof such as "includes" or "includes" and the like will be understood to include the stated elements or constituents, and not Other elements or other components are not excluded.

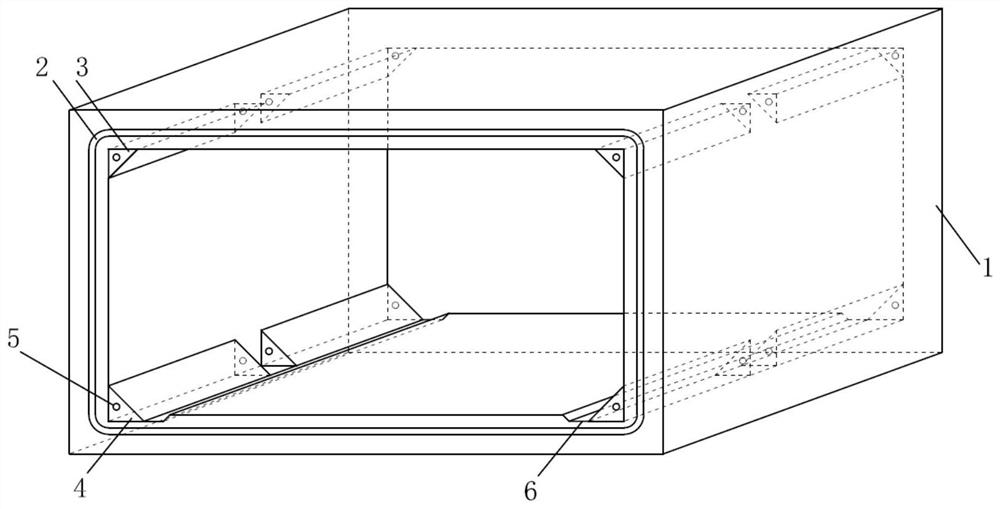

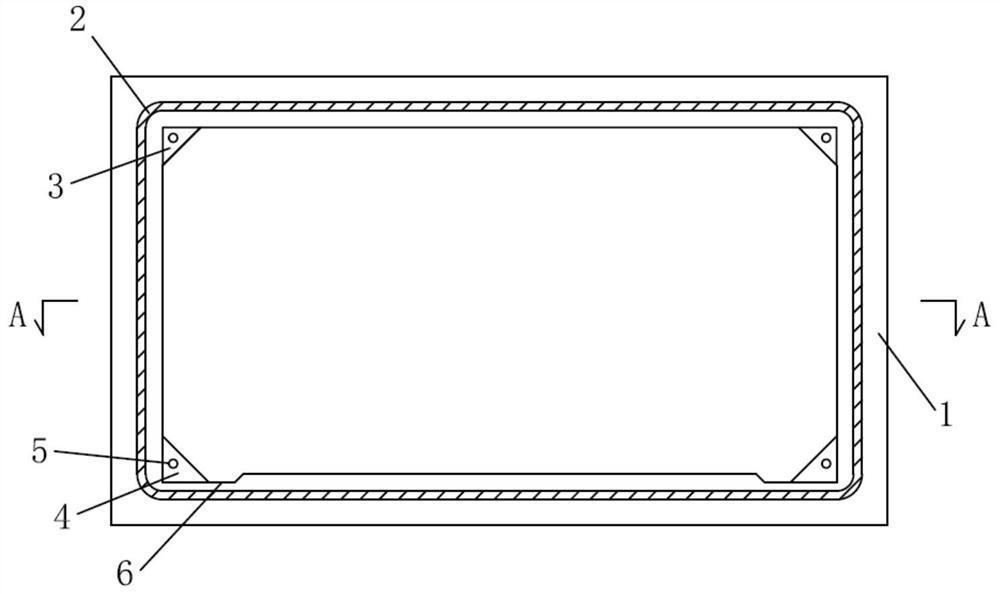

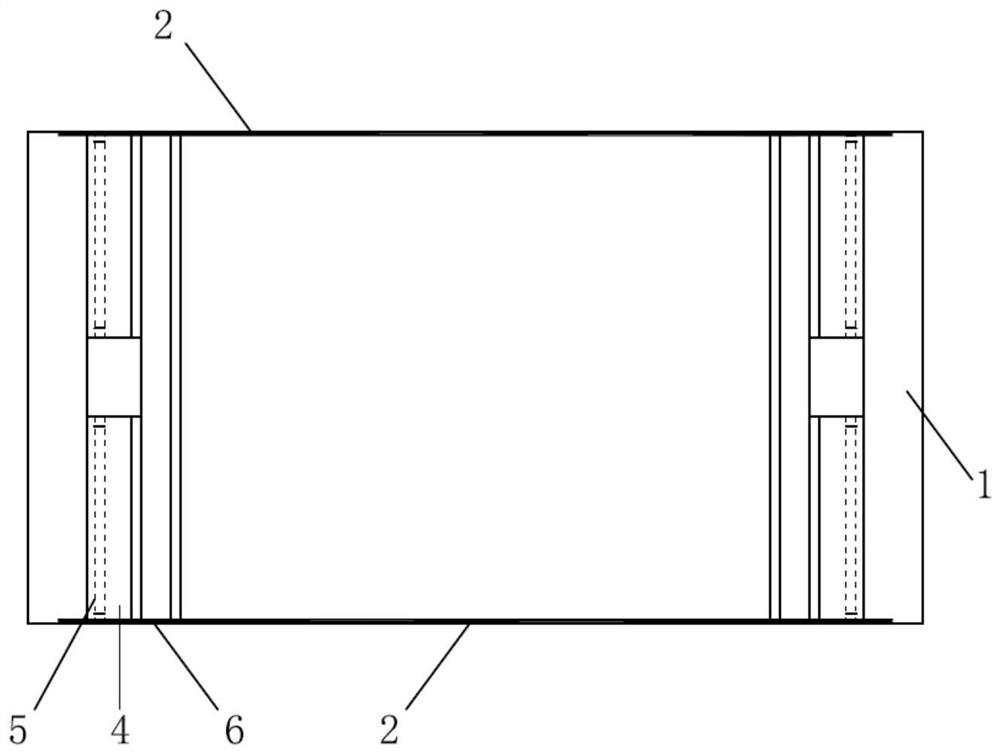

[0038] Figure 1~Figure 8 As shown, a semi-rigid assembled comprehensive pipe gallery is a prefabricated component of reinforced concrete. The main corridor body of the semi-rigid prefabricated integrated pipe gallery is transported to the construction site for assembly after prefabrication in the processing plant. Excavate a foundation pit of appropriate size at the construction site of the comprehensive pipe gallery and do a good job of supporting; carry out foundation tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com