Impact-resistant and wear-resistant fabricated concrete road and construction method thereof

A concrete road, prefabricated technology, applied in the direction of roads, roads, climate change adaptation, etc., can solve the problems of long road construction period and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

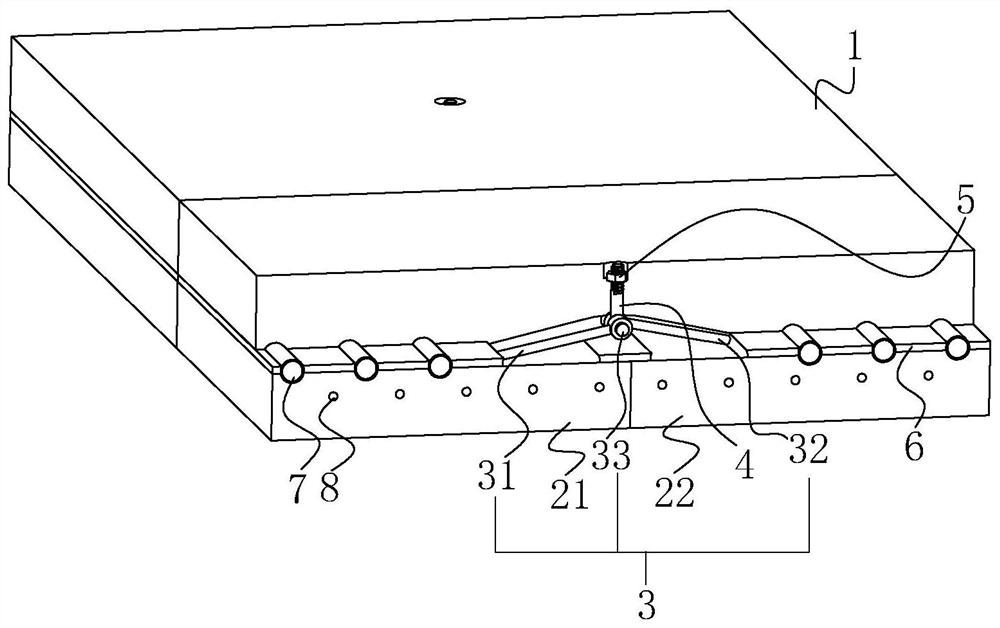

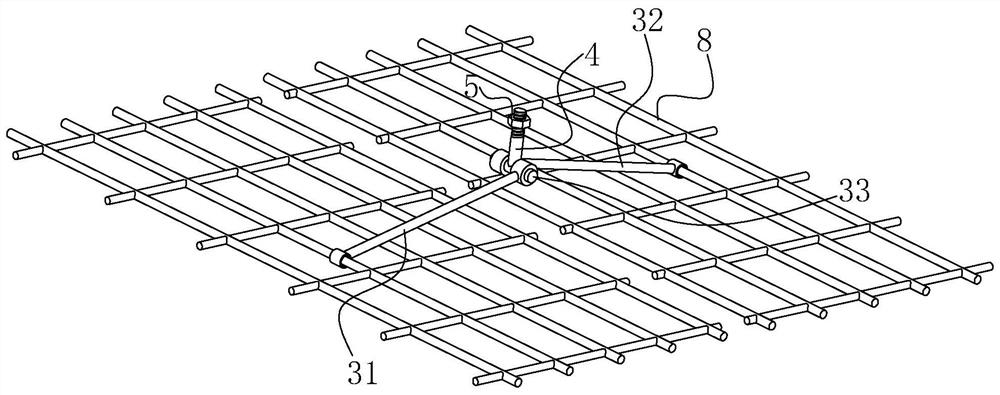

[0034] The following is attached Figure 1-2 The application is described in further detail.

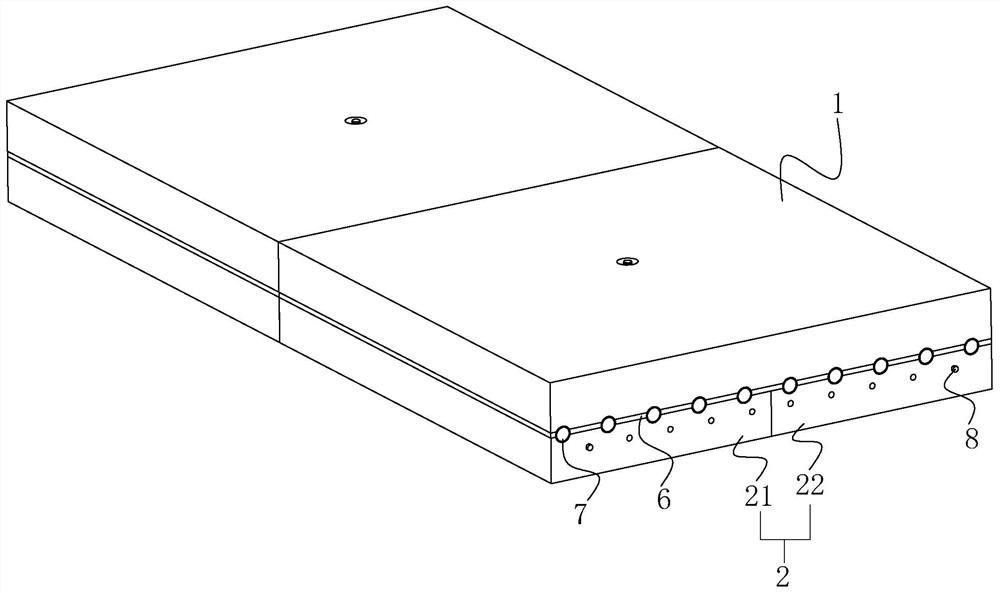

[0035] The embodiment of the present application discloses an impact-resistant and wear-resistant fabricated concrete road. refer to figure 1 The impact-resistant and wear-resistant assembled concrete road includes a number of concrete slabs laid on the roadbed, the concrete slabs include an upper road slab 1 and a lower road slab 2, and a number of grouting pipes 7 are placed between the upper road slab 1 and the lower road slab 2 , There are grouting holes (not shown in the figure) on the grouting pipe 7.

[0036] refer to figure 1, the upper road slab 1 and the lower road slab 2 are both reinforced concrete structures, the grouting pipe 7 is embedded in the side of the lower road slab 2 close to the upper road slab 1, part of the grouting pipe 7 is sunk into the lower road slab 2, and part of it protrudes from the lower road The surface of the panel 2 is embedded in the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com