Low-resistivity P-type 4H-SiC single crystal and preparation method thereof

A low-resistivity, 4h-sic technology, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of low success rate and long experiment period, achieve good quality and improve doping uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

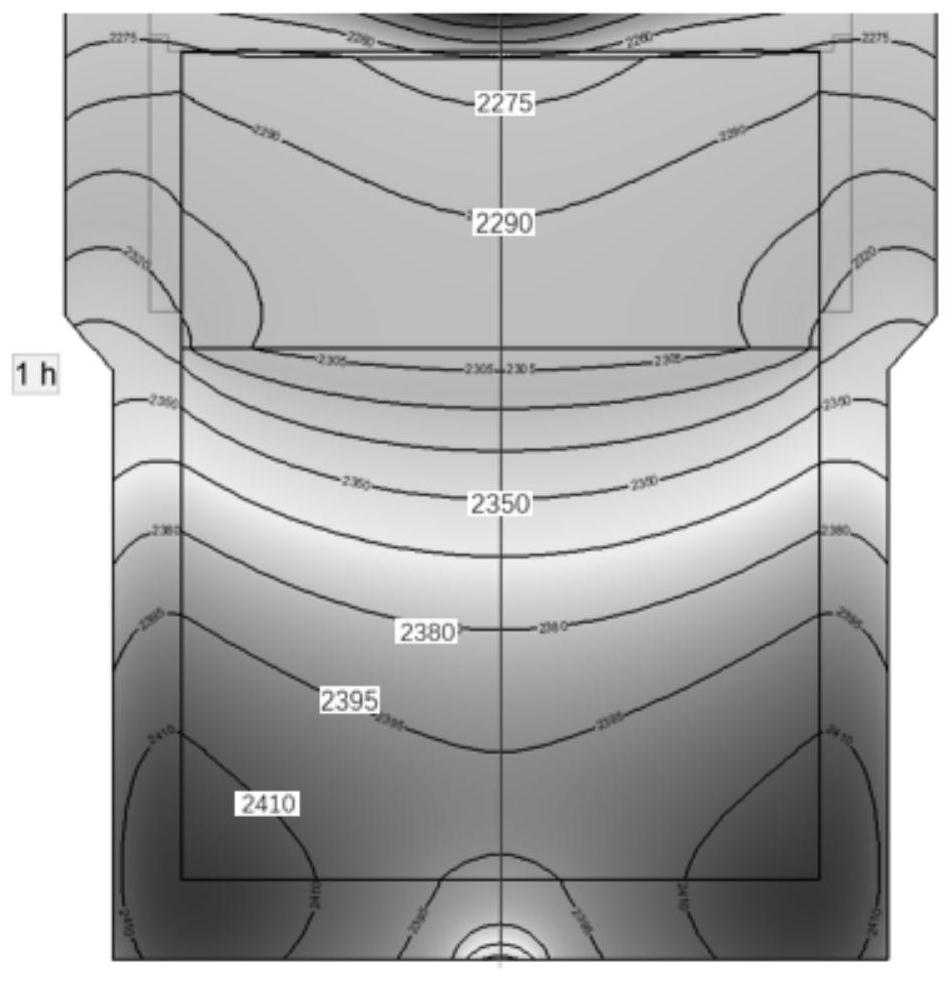

[0043] In this example, a growth pressure of 10 mbar is selected to ensure the growth rate of the crystal. The temperature at the center point of the upper lid of the crucible can be directly measured by an infrared thermometer during the actual growth of a single crystal, and the temperature change will have an important impact on the temperature field in the growth chamber. Combined with the temperature growth conditions of 4H-SiC single crystal, the temperature of the center point of the upper lid of the crucible was set to 2210 °C, 2230 °C, and 2250 °C, respectively, and the growth pressure was 10 mbar for temperature field simulation. Depending on the required calculation accuracy, in VR-PVT SiC TM The numerical simulation software is set to divide the calculation grid and optimize and adjust the grid. The heating method is radio frequency heating, and the heating power is set to follow the set temperature of the center point of the upper lid of the crucible for fitting,...

Embodiment 2

[0049] In this example, the growth simulation of 100mm p-type 4H-SiC single crystal is studied, the growth model is constructed according to the growth requirements, the material properties and boundary conditions of each module are defined, the calculation grid is divided and the grid is optimized and adjusted. Set the heating mode to select radio frequency heating, the heating power is fitted with the set temperature of the center point of the upper lid of the crucible, and the editing growth time is 24h. Firstly, the influence of different pressures on the temperature field was studied, and the center temperature of the upper lid of the crucible was defined as 2530℃, and the growth pressures in the cavity were changed to 10mbar, 50mbar, and 100mbar, respectively. The temperature field under different growth pressures in the cavity, the material transport path at each preset time node and the state diagram of SiC powder are obtained. The simulation results show that the chan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com