Quick-drying water-resistant exposed waterproof coating

A waterproof coating, exposed technology, applied in the direction of coating, etc., can solve the problems of slow reaction speed and general curing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

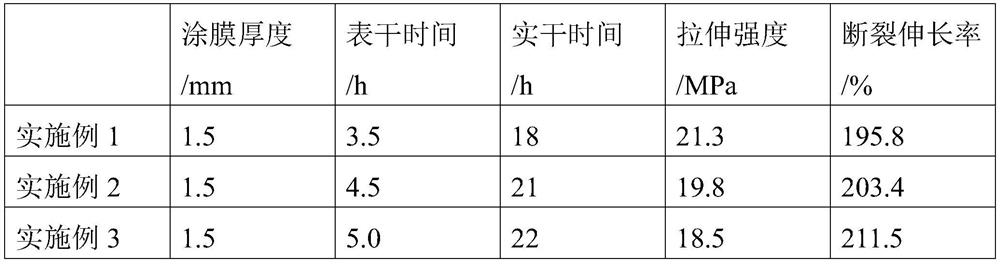

Embodiment 1

[0045] A kind of waterproof paint, comprises the raw material preparation of following weight part and obtains: Polyether polyol (purchased from Dow Chemical, product brand is SPECFLEX TM NC 138, the molecular weight is 5803, the hydroxyl value is 29mg KOH / g, the functionality is 3) 3 parts, polyethylene glycol (molecular weight is 3000, purchased from Jiangsu Haian Petrochemical Factory, specification PEG-3000) 12 parts, all Fluorohexyl ethyl acrylate (CAS No. 17527-29-6, purchased from Wuhan Fengtai Weiyuan Technology Co., Ltd., purity 98.0%) 5 parts, polyether ether ketone oligomer 6 parts, polyisocyanate 22 parts, catalyst two Dibutyltin laurate (purchased from Nantong Haotai Chemical Products Co., Ltd., tin content: 18.50±0.50%) 0.05 parts, acetone (commercially available industrial product) 0.03 part, ethylenediamine (commercially available industrial product) 1.6 part;

[0046] Described polyisocyanate is the mixture of isophorone diisocyanate (commercially available i...

Embodiment 2

[0051] This embodiment is basically the same as the waterproof coating in Example 1. The difference is that the waterproof coating comprises the following raw materials in parts by weight: TM NC 138, molecular weight is 5803, hydroxyl value is 29mg KOH / g, functionality is 3) 2 parts, polyethylene glycol (molecular weight is 3000, purchased from Jiangsu Province Haian Petrochemical Factory, specification PEG-3000) 6 parts, all Fluorohexyl ethyl acrylate (CAS No. 17527-29-6, purchased from Wuhan Fengtai Weiyuan Technology Co., Ltd., purity 98.0%) 5 parts, polyether ether ketone oligomer 6 parts, polyisocyanate 18 parts, catalyst two Dibutyltin laurate (purchased from Nantong Haotai Chemical Products Co., Ltd., tin content: 18.50±0.50%) 0.03 parts, acetone (commercially available industrial product) 0.03 part, ethylenediamine (commercially available industrial product) 2.2 parts;

[0052] With the rest unchanged, the waterproof coating was prepared according to the method of Exa...

Embodiment 3

[0054] This embodiment is basically the same as the waterproof coating in Example 1. The difference is that the waterproof coating comprises the following raw materials in parts by weight: TM NC 138, the molecular weight is 5803, the hydroxyl value is 29mg KOH / g, the functionality is 3) 4 parts, polyethylene glycol (molecular weight is 3000, purchased from Jiangsu Haian Petrochemical Factory, specification PEG-3000) 18 parts, all Fluorohexyl ethyl acrylate (CAS No. 17527-29-6, purchased from Wuhan Fengtai Weiyuan Technology Co., Ltd., purity 98.0%) 8 parts, 10 parts of polyether ether ketone oligomer, 30 parts of polyisocyanate, catalyst two Dibutyltin laurate (purchased from Nantong Haotai Chemical Products Co., Ltd., tin content: 18.50±0.50%) 0.1 part, acetone (commercially available industrial product) 0.04 part, ethylenediamine (commercially available industrial product) 2.8 parts;

[0055] With the rest unchanged, the waterproof coating was prepared according to the meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com