Preparation method of SUZ-4 molecular sieve

A SUZ-4, molecular sieve technology, applied in molecular sieve compounds, molecular sieve characteristic silicates, chemical instruments and methods, etc., can solve the problems of high price and unenvironmental protection, and achieve reduced preparation costs, low procurement costs, and mature synthesis technology. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

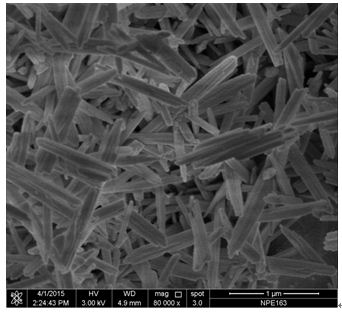

Image

Examples

Embodiment 1

[0027]Aluminum sheet, potassium hydroxide, silica sol (26.5% SIO2) And water according to the molar ratio SIO2: Al2O3: Koh: h2O = 16.5: 1: 11.5: 585.0 Add to the beaker, the HZSM-5 molecular sieve is added to 9% of the total mass of the initial gel mixture synthesized SUZ-4 molecular sieve, stirred for 2 hours, the solution is uniform, and the reaction reaction is loaded. The kettle was placed in a dynamic crystallization of 150 ° C for 3 days (rotational speed of 20R / min). After removing the reactor, it was quickly cooled to room temperature with cold water, and the resulting mixture was separated. The resulting solid sample was dried at 110 ° C for 24 hours to obtain a SUZ-4 molecular sieve, and no heterocrystallization, the relative crystallinity was 96%.

Embodiment 2

[0029]Example 1 was repeated, but with white carbon black as a silicon source, the amount of deionized water was reduced. In this embodiment, aluminum sheet, potassium hydroxide, silica sol and water are in accordance with the molar ratio SiO2: Al2O3: Koh: h2O = 27.5: 1.5: 12.8: 765.0 Add to the beaker, the HzSM-5 molecular sieve is added to 6.5% of the total mass of the initial gel mixture synthesizing the SUZ-4 molecular sieve, stirred for 2 hours, the solution is uniform, and the reaction reaction is loaded. Dynamic crystallization of 170 ° C for 2 days (20R / min) was placed. After removing the reactor, it was rapidly cooled to room temperature after removal of the reaction, and the resulting mixture was filtered to be separated, and the solid Suz-4 molecular sieve was obtained at 110 ° C for 24 hours, and did not contain a heteroid crystal, and the relative crystallinity was 98%.

Embodiment 3

[0031]Example 1 was repeated, but alumina as an aluminum source, alumina, potassium hydroxide, silica sol (26.5% SiO2) And water according to the molar ratio SIO2: Al2O3: Koh: h2O = 18.8: 1.8: 1: 6.5: 500.0 Add to the beaker, the HZSM-5 molecular sieve is added to 14% of the total mass of the initial gel mixture synthesized SUZ-4 molecular sieve, stirred for 2 hours, solution liquid into a uniform state, After the reactor was placed at 160 ° C for 3 days (20 r / min) to obtain a SUZ-4 molecular sieve containing no heterocrystalline, the relative crystallinity was 96%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com