Graphene solar water cleaning foam and its preparation method and use

A technology of cleaning foam and solar energy, applied in the direction of graphene, chemical instruments and methods, energy input, etc., can solve the problems that graphene needs to be further studied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] 1. Prepare 2mg·mL by oxidized exfoliated graphite (Hummers) method -1 Graphene oxide aqueous solution;

[0068] 2. Mix 200 μL of ethanol with 20 mL of the graphene oxide aqueous solution prepared in step 1 and stir evenly to obtain a mixed solution;

[0069] 3. Freeze the mixed solution obtained in step 2 into blocks at -20°C, and then freeze-dry in a freeze dryer for 24 hours to obtain a graphene oxide foam;

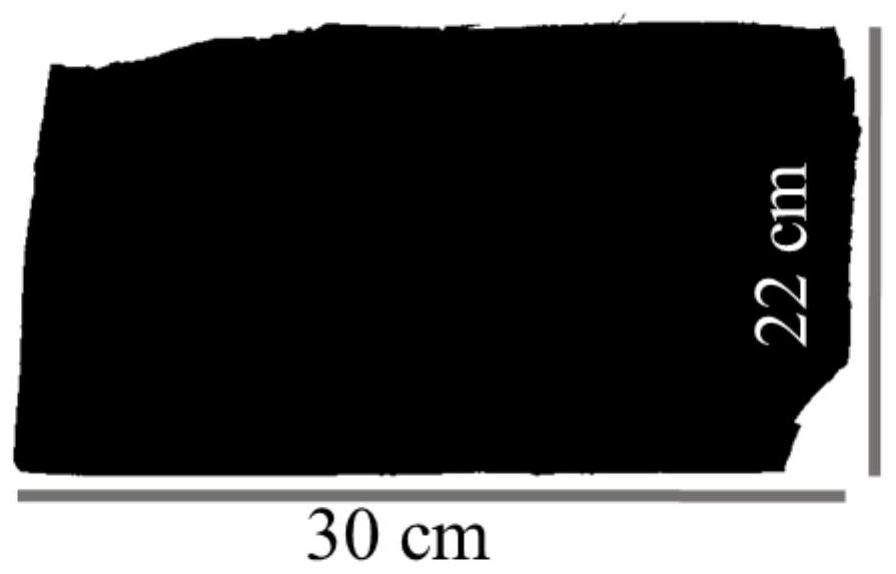

[0070] 4. the graphene oxide foam in step 3 is under argon protection, is heated to 500 ℃ and annealed for 2h to obtain graphene solar water cleaning foam (photo as figure 2 ), the density is 1mg·cm -3 :

[0071] Scanning electron microscope (JSM-7500F, Shimadzu Corporation, Japan) ( image 3 ) characterizes that the inside of the prepared graphene solar water cleaning foam is a three-dimensional porous structure;

[0072] Absorption test (Cary 5000, Varian, USA) absorption spectrum as shown in Figure 4 As shown, the prepared graphene solar water cleaning...

Embodiment 2

[0083] 1. Prepare 15mg·mL by oxidized exfoliated graphite (Hummers) method -1 Graphene oxide aqueous solution;

[0084] 2. Mix 100 μL of ethanol with 20 mL of the graphene oxide aqueous solution prepared in step 1 and stir evenly to obtain a mixed solution;

[0085] 3. Freeze the mixed solution obtained in step 2 into a block at -20°C, and then freeze-dry it in a freeze dryer for 72 hours to obtain a graphene oxide foam;

[0086] 4. Under the protection of argon, heat the graphene oxide foam in step 3 to 1000°C for annealing treatment for 4 hours, and then compress its volume to 1 / 2 of the original volume to obtain graphene solar water cleaning foam with a density of 30mg cm -3 ;

[0087] The inside of the prepared graphene solar water cleaning foam was characterized by scanning electron microscopy as a three-dimensional porous structure;

[0088] Absorption test (Cary 5000, U.S. Varian) characterizes the prepared graphene solar water cleaning foam in the ultraviolet regio...

Embodiment 3

[0093] 1. Prepare 8 mg·mL by oxidation exfoliated graphite (Hummers) method -1 Graphene oxide aqueous solution;

[0094] 2. Mix 200 μL of ethanol with 20 mL of the graphene oxide aqueous solution prepared in step 1 and stir evenly to obtain a mixed solution;

[0095] 3. Freeze the mixed solution obtained in step 2 into a block at -20°C, and then freeze-dry it in a freeze dryer for 72 hours to obtain a graphene oxide foam;

[0096] 4. The graphene oxide foam in step 3 is irradiated with a laser with a power of 1W for 1s to obtain a graphene solar water cleaning foam;

[0097] The inside of the prepared graphene solar water cleaning foam was characterized by scanning electron microscopy as a three-dimensional porous structure;

[0098] Absorption test (Cary 5000, U.S. Varian) characterizes the prepared graphene solar water cleaning foam in the ultraviolet region and about 99% of visible light, and near 100% absorption in near-infrared light;

[0099] Solar water evaporation a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com