Uniform wooden stick polishing device

A uniform and stick technology, applied in the direction of grinding drive device, grinder, grinding frame, etc., can solve the problems that new employees are not easy to control the grinding allowance of wooden sticks, and the grinding efficiency is low, so as to achieve the convenient grinding allowance. , Improve the grinding effect, reduce the effect of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

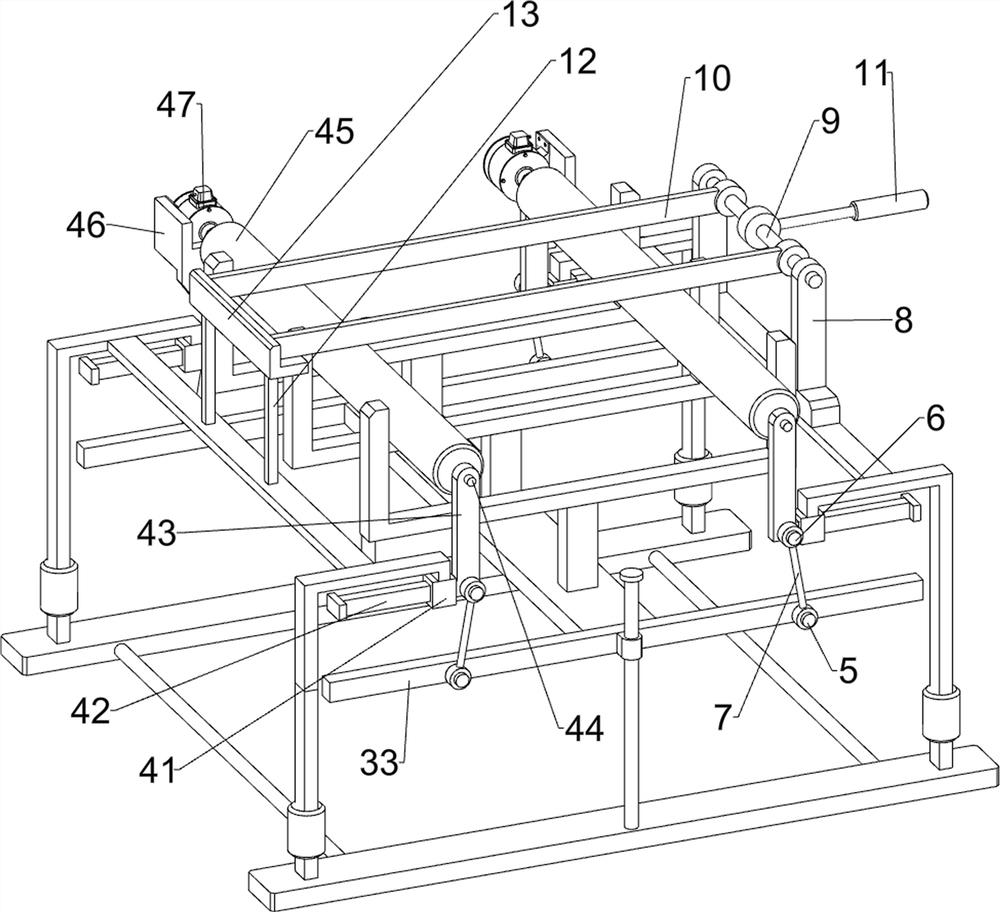

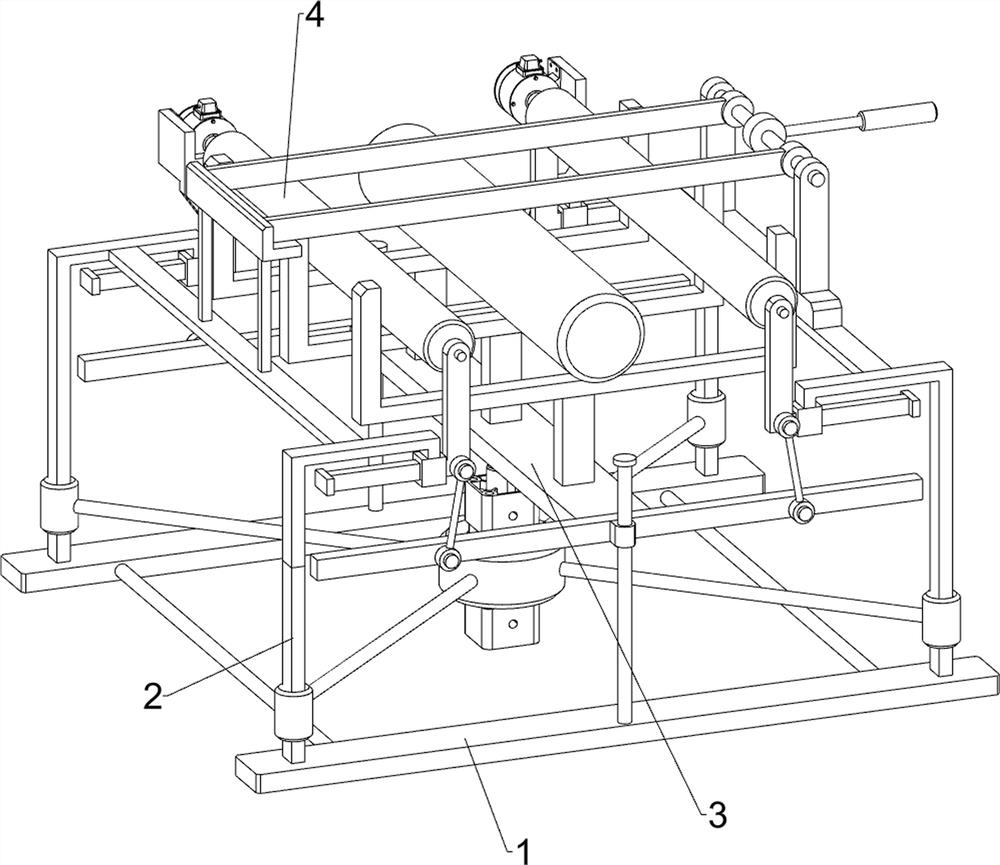

[0020] like figure 1 , figure 2 and image 3 As shown, a wooden stick uniform grinding device includes a base plate 1, a bracket 2, a lifting mechanism 3 and a grinding mechanism 4, a bracket 2 is evenly arranged around the top of the base plate 1, a lifting mechanism 3 is arranged in the middle of the top of the base plate 1, and a lifting mechanism 3 is arranged on the top of the bracket 2. A grinding mechanism 4 is provided.

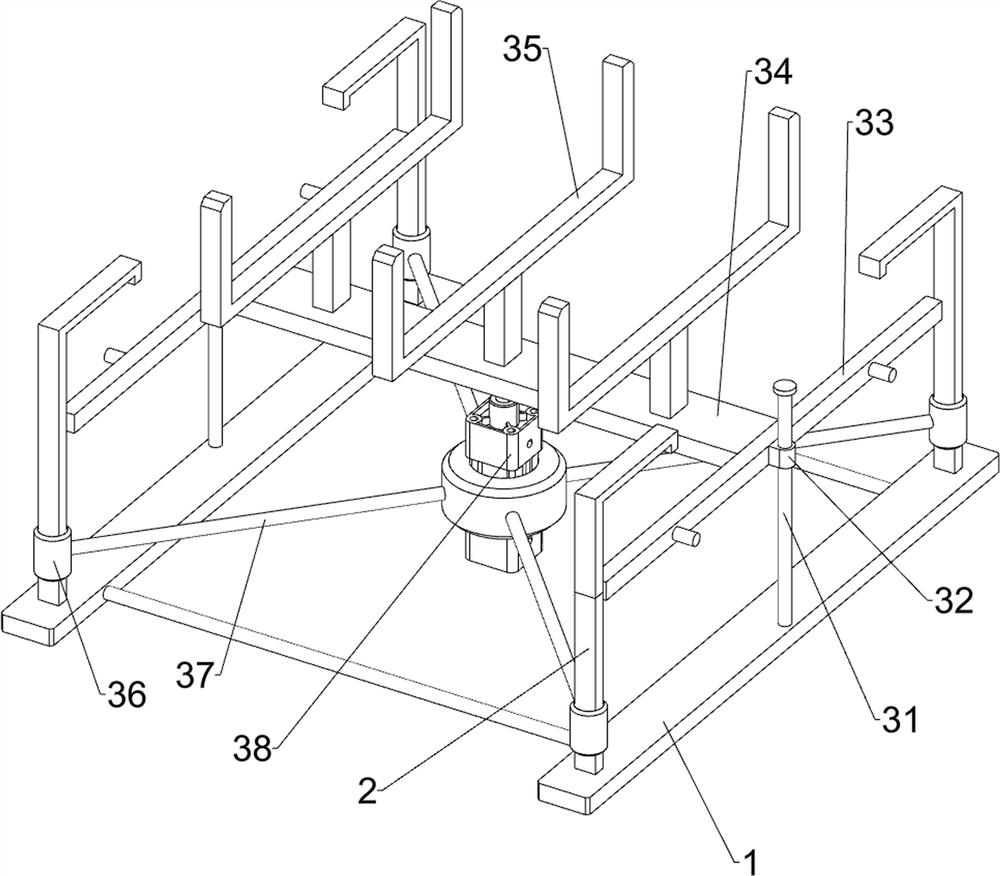

[0021] The lifting mechanism 3 includes a guide rod 31, a first slide block 32, a push rod 33, a connecting block 34, a first placing block 35, a first fixing block 36, a first fixing rod 37 and a hydraulic cylinder 38, and the bottom plate 1 is arranged symmetrically in the middle There are two guide rods 31, the guide rod 31 is provided with a first slide block 32, one side of the first slide block 32 is provided with a push rod 33, a connection block 34 is fixedly connected between the two push rods 33, and the top of the connection block 34 Th...

Embodiment 2

[0025] like image 3 As shown, on the basis of Embodiment 1, a second fixed rod 5, a third fixed rod 6 and a connecting rod 7 are also included, and the push rod 33 is symmetrically provided with the second fixed rod 5 near the side of the guide rod 31. The side of the second slider 42 close to the first bearing seat 43 is provided with a third fixed rod 6 , and the second fixed rod 5 and the third fixed rod 6 are hingedly connected by a connecting rod 7 .

[0026] In addition, when the hydraulic cylinder 38 drives the connecting block 34 to move upward, the push rod 33 drives the connecting rod 7 hinged therewith to move the first bearing seat 43 to move inward, and the two first bearing seats 43 drive the grinding mechanism respectively. 4. The overall movement is inward, which can fully meet the grinding needs of wooden sticks with different diameters, and at the same time, it is convenient to control the grinding allowance.

[0027] It also includes a second bearing seat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com