Electromagnetic auxiliary laser welding method for pre-arranged powder on surface of aluminum alloy

An aluminum alloy surface, pre-powder technology, used in laser welding equipment, welding equipment, welding/welding/cutting items, etc., can solve problems such as easy generation of pores, reduce pores, reduce powder loss, and improve weld formation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

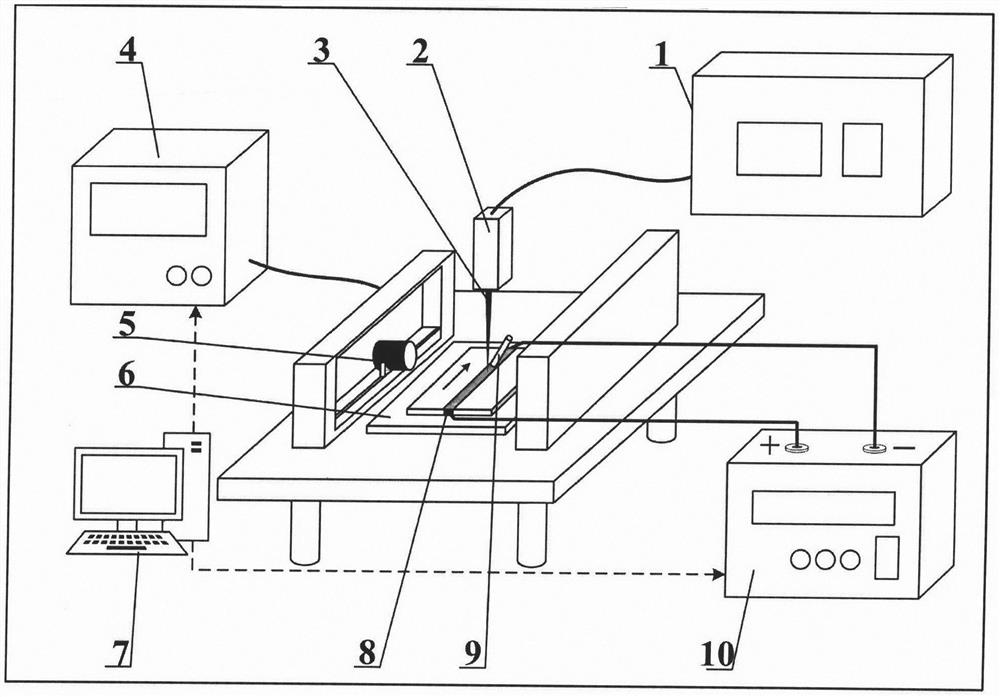

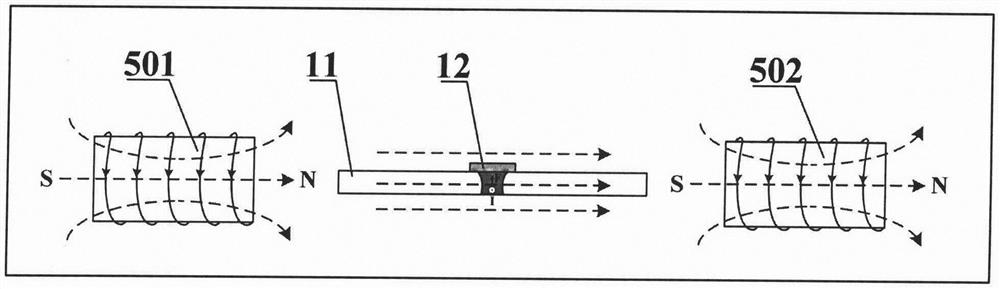

[0033] Combine below Figure 1-2 And example the present invention is described in further detail. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention.

[0034] An electromagnetic-assisted laser welding method for pre-preparing powder on the surface of an aluminum alloy of the present invention comprises the following steps:

[0035] 1) Selection of welding materials: 2219 aluminum alloy is selected, and its composition is: Si: ≤0.20%; Fe: ≤0.30%; Cu: 5.8-6.8%; Mn: 0.20-0.40%; Mg: ≤0.02%; V: 0.05-0.15%; Zr: 0.10-0.25%; Zn: ≤0.10%; Ti: 0.02-0.10%; Side thickness 6mm, spacing 0.8mm;

[0036] 2) Selection of welding equipment: a laser welding device consisting of KUKA robot KR30HA, TruDisc-12003 disc laser (1) and manipulator. The maximum laser power is 12kW, the wavelength is 1030nm, and the minimum diameter of the optical fiber is 300μm;

[0037] 3) Base material treatmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com